You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spike Conical- observations and best practices

- Thread starter sheikyerbouti

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Just not gonna do it. It may even be 20 feet. I’m just not gonna deal with all that hose and the sanitation n cleaning that comes with it.

I’ll figure something out. I always do. Last time I had an issue about lifting my brew in a basket filled with wet grain I built a unistrut lift and trolley mechanism on my ceiling using a hoist.

2 min mark in my vid here:

I’m sure if it comes down to it I can built another lifting mechanism to wrap around the bottom of the cone and gently raise it into

The fridge.

Did you see how mongoose’s fermentor shook when he thumped the valve adding his dry hops? I don’t believe these are designed to be mobile when full.

Cleaning and Sanitizing a 20 foot line is really not really any more work than sanitizing a 5’ line. Connect it to a pump and circulate PBW. Run sanitizer through it before use.

I clean it well, then put it back in the box. I sanitize it before i fill it on brew day

you put the conical back in the box? to each their own but seems like overkill (unless you don't have a 'permanent' brew space). after a pbw cleaning, i spray with starsan, put the domed lid/gasket on (barely clamped), set the 4" gasket/cover (no clamp) and set the 90 degree blowoff gasket/fitting (no clamp). this is more or less to keep any falling dust out, all the other ports are open. before filling with wort, i give it another good starsan spray. the starsan after cleaning is probably unnecessary but that's just me being over cautious (plus i always have about 5 gal of starsan around so why not).

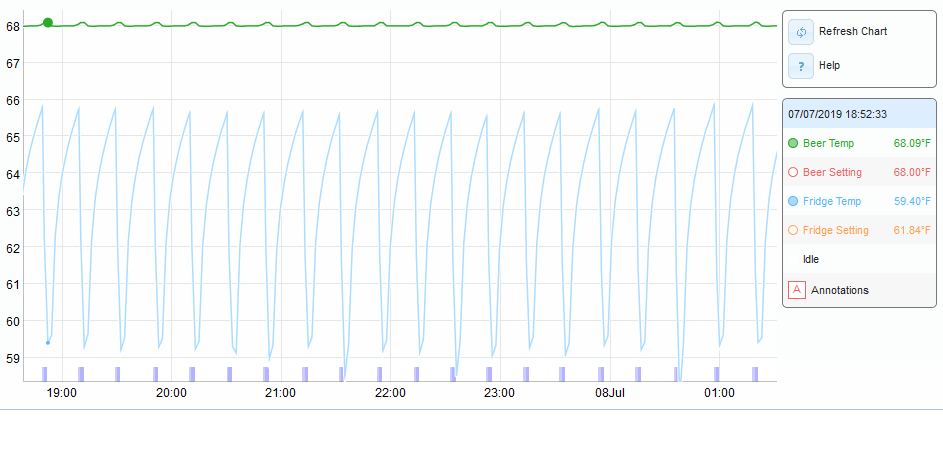

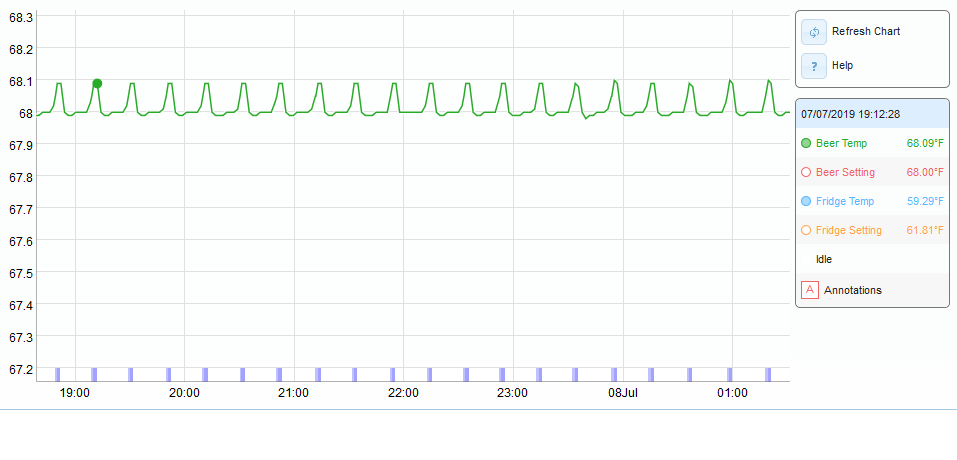

Here's my fridge based system. Precise enough?

I get that your temp control is an order of magnitude better than what I can do. It’s impressive for sure and provides solid data to answer question about whether glycol is inherently more precise than fridge/freezer chiller based system.

My guess is with Brewpi you could achieve similar control with a glycol chiller in your loop instead of a freezer. Is that reasonable?

I’m fascinated by the brewpi idea as I get the power of PID, but as much as I like DIY...even built a controller for my mash tun modeled off blichman tower of power ...every time I try to read the instructions about how to DIY Brewpi my head actually explodes. Sorry about the rant but I’d surely appreciate it if someone would post a Brewpi DIY for non engineers thread.

Also. Your temp control is about an order of magnitude better than mine. You are controlling within 0.1F and I’m controlling within 1.0F. I suspect this actual difference may not really matter. Not sure where the boundary is but most yeast strains I’ve seen post optimal temperature ranges of about 10F. That’s an order of magnitude wider than my +/- 1.0F system...I’m really on board with upgrading, its a hobby and this stuff is fun, but do you think +/-0.1F is worth chasing when I’m already at +/-1.0F?

So you are managing overshoot the same way I am...by manually moderating the temp differences. I believe it works well as it does for me but aren’t you limiting one of the key advantages of a glycol system ... being able to provide chilling to multiple fermentors ... when you do this? Say you wanted to cold crash fermentor A while maintaining 65F in fermentor B?

Oh sure...pick on the guy with only one fermenter.

If and when I get a second--it's on my dream list, of course--I'll have to figure a workaround for it. Or drop the temp on the glycol chiller not to 28 but maybe to....40? I have never gone colder than about 45 degrees, but maybe colder would work.

Or I'll have to deal with a little bit of ping-ponging.

As a side note--the recovery of the Penguin is rather impressive. I don't know what it would be running 2, or 3, or even 4 fermenters. Probably still pretty good but who knows.....

you put the conical back in the box? to each their own but seems like overkill (unless you don't have a 'permanent' brew space). after a pbw cleaning, i spray with starsan, put the domed lid/gasket on (barely clamped), set the 4" gasket/cover (no clamp) and set the 90 degree blowoff gasket/fitting (no clamp). this is more or less to keep any falling dust out, all the other ports are open. before filling with wort, i give it another good starsan spray. the starsan after cleaning is probably unnecessary but that's just me being over cautious (plus i always have about 5 gal of starsan around so why not).

I do more or less the same thing. Once it's sanitized (I also spray down mine), I close it up, and that is fine. A quick squirt of Star-San before filling and I'm good. I usually cover up the tri-clamp ports with the plastic covers that came with it or with other parts, to keep flies and such from landing on them and spreading bacteria that way.

I can't imagine why repacking it in the box would be better than that--you'd still have to sanitize it. Maybe it's a storage thing.

ZmannR2

Well-Known Member

Cleaning and Sanitizing a 20 foot line is really not really any more work than sanitizing a 5’ line. Connect it to a pump and circulate PBW. Run sanitizer through it before use.

You may be right. I just went and measured how deep the fridge is, it will come too close to my truck if I put it by my BK.

So if I run that long ass hose, do I put my pump closest to the fermenter? Way I figure is, there’s much less line losses because the pump will “suck” wort all the way too the CF10 therein emptying most of the line completely upon running out. I know I would have to prime it, but the BK is up high and I can lay the hose on the ground

I get that your temp control is an order of magnitude better than what I can do. It’s impressive for sure and provides solid data to answer question about whether glycol is inherently more precise than fridge/freezer chiller based system.

My guess is with Brewpi you could achieve similar control with a glycol chiller in your loop instead of a freezer. Is that reasonable?

I’m fascinated by the brewpi idea as I get the power of PID, but as much as I like DIY...even built a controller for my mash tun modeled off blichman tower of power ...every time I try to read the instructions about how to DIY Brewpi my head actually explodes. Sorry about the rant but I’d surely appreciate it if someone would post a Brewpi DIY for non engineers thread.

Also. Your temp control is about an order of magnitude better than mine. You are controlling within 0.1F and I’m controlling within 1.0F. I suspect this actual difference may not really matter. Not sure where the boundary is but most yeast strains I’ve seen post optimal temperature ranges of about 10F. That’s an order of magnitude wider than my +/- 1.0F system...I’m really on board with upgrading, its a hobby and this stuff is fun, but do you think +/-0.1F is worth chasing when I’m already at +/-1.0F?

I think I have heard of people using brewpi with glycol systems even though it wasn't designed for them, but you would have to look around to make sure. And yeah, the brewpi setup made my head explode several times, but somehow I got through it. I think there might be turn-key systems available now.

I think tighter temp control may be worth it, but there are other advantages to brewpi like data logging, setting ramp ups and downs, and super simple viewing progress or changing temps from your phone or computer.

You may be right. I just went and measured how deep the fridge is, it will come too close to my truck if I put it by my BK.

So if I run that long ass hose, do I put my pump closest to the fermenter? Way I figure is, there’s much less line losses because the pump will “suck” wort all the way too the CF10 therein emptying most of the line completely upon running out. I know I would have to prime it, but the BK is up high and I can lay the hose on the ground

My pump is close to my BK. I think you are overly concerned about line losses.

You may be right. I just went and measured how deep the fridge is, it will come too close to my truck if I put it by my BK.

So if I run that long ass hose, do I put my pump closest to the fermenter? Way I figure is, there’s much less line losses because the pump will “suck” wort all the way too the CF10 therein emptying most of the line completely upon running out. I know I would have to prime it, but the BK is up high and I can lay the hose on the ground

I would put the pump close to the BK. When the BK is empty, disconnect the hose at the pump and raise it higher than the fermenter. The wort in the hose will gravity drain into the fermenter.

My pump is close to my BK. I think you are overly concerned about line losses.

But I get the concern. So found an online calc ... 1/2 inch x 20 ft = 0.2 gallons. 3/8 inch x 20 ft = 0.086 gallons. I’d go with the 3/8” line (I do) for wort savings and cause the line is less expensive. But really understand the difference is between 1% and 2% of your 10 gallon batch. Vs hurting either your conical or your back the line loss is just not something to sweat. Also FWIW I tend to use the wort in the line for my OG sample.

you put the conical back in the box? to each their own but seems like overkill (unless you don't have a 'permanent' brew space). after a pbw cleaning, i spray with starsan, put the domed lid/gasket on (barely clamped), set the 4" gasket/cover (no clamp) and set the 90 degree blowoff gasket/fitting (no clamp). this is more or less to keep any falling dust out, all the other ports are open. before filling with wort, i give it another good starsan spray. the starsan after cleaning is probably unnecessary but that's just me being over cautious (plus i always have about 5 gal of starsan around so why not).

Correct... no permanent brew space. We sold the house to move for my job (gotta pay for this hobby) and the house we just started renting does not have the third room so i was kicked out to the garage. The 80 year old non insualted garage. Since i had the box i figured why not store in it? (I dont brew weekly). I figure it keeps spiders and dust out. Agree it is overkill.

My understanding is as long as you clean it first ( aka pbw or oxiclean) then you can sanitize right before use. Worked for me so far.

I throw the thing in a box up high in the rafters so i like having the box. Keeps it from getting dents dings scratches etc.

ZmannR2

Well-Known Member

I throw the thing in a box up high in the rafters so i like having the box. Keeps it from getting dents dings scratches etc.

And garage dust/dirt. I park two full sized vehicles, 3 dirt bikes, a golf cart, and a zero turn in my garage. My brewery gets dirty. Bout to start tarping it. Dirt sucks! Lol

3 dirt bikes AND a golf cart?!?!? Dang i would never have time to brew with those toys!!! LolAnd garage dust/dirt. I park two full sized vehicles, 3 dirt bikes, a golf cart, and a zero turn in my garage. My brewery gets dirty. Bout to start tarping it. Dirt sucks! Lol

ITV

Well-Known Member

Just not gonna do it. It may even be 20 feet. I’m just not gonna deal with all that hose and the sanitation n cleaning that comes with it.

I have taken my plastic fermenter (one with a spigot) and lifted it on top of my fridge and gravity feed it into my conical. For a 10 gallon batch I would fill the fermenter twice.

- Joined

- Aug 8, 2017

- Messages

- 1,509

- Reaction score

- 1,781

What's the fan for in front of your DIY glycol chiller? DO you need to help the chiller cool or is just to keep your garage/ brew room cool?

MS summer in July, gotta stay cool! I usually keep my glycol cooler at 40-60deg just depends on what I’m fermenting. I can get it down to about 28deg when cold crashing. Really surprising how little it runs to keep cool.

ZmannR2

Well-Known Member

You know that gives me an idea. Instead of moving the fermenter to my BK to fill it, move the BK to the fermenter. Maybe find me a cart with casters to wheel it over.I have taken my plastic fermenter (one with a spigot) and lifted it on top of my fridge and gravity feed it into my conical. For a 10 gallon batch I would fill the fermenter twice.

Edit: I’ve got it!!! Purchase universal casters to go on my stainless table. Unbolt it from the wall and wheel that bastard to my fridge with the boil kettle still sitting on it after it’s chilled to ferm temps

Last edited:

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

I would suggest moving it prior to chilling to avoid disturbing all the crap. CheersYou know that gives me an idea. Instead of moving the fermenter to my BK to fill it, move the BK to the fermenter. Maybe find me a cart with casters to wheel it over.

Edit: I’ve got it!!! Purchase universal casters to go on my stainless table. Unbolt it from the wall and wheel that bastard to my fridge with the boil kettle still sitting on it after it’s chilled to ferm temps

ZmannR2

Well-Known Member

Ok onto OXYGENATING YOUR WORT in Conicals.

For the last several years I’ve simply held my hose really high and let it “splash” it’s way into the fermenter always causing tons of bubbles as it fills up. And that method has never let me down. However I never had all these handy ports at my expense. Is the carb stone attachment sold by Spike worth the cost just for oxygenating? How is everyone oxygenating your wort in your CF?

Also, what kinda air pump would y’all suggest if I did grab the carb stone?

However Brülosophy did this experiment in 4 different ways and never found oxygenating the wort to cause any kid of distinguishable difference in the beer:

http://brulosophy.com/2015/05/25/wort-aeration-pt-1-shaken-vs-nothing-exbeeriment-results/

For the last several years I’ve simply held my hose really high and let it “splash” it’s way into the fermenter always causing tons of bubbles as it fills up. And that method has never let me down. However I never had all these handy ports at my expense. Is the carb stone attachment sold by Spike worth the cost just for oxygenating? How is everyone oxygenating your wort in your CF?

Also, what kinda air pump would y’all suggest if I did grab the carb stone?

However Brülosophy did this experiment in 4 different ways and never found oxygenating the wort to cause any kid of distinguishable difference in the beer:

http://brulosophy.com/2015/05/25/wort-aeration-pt-1-shaken-vs-nothing-exbeeriment-results/

Last edited:

I have an oxygin wand i use from before the cf5. I use the disposable tanks from hardware store. Get about 3 batches or so per tank.Ok onto OXYGENATING YOUR WORT in Conicals.

For the last several years I’ve simply held my hose really high and let it “splash” it’s way into the fermenter always causing tons of bubbles as it fills up. And that method has never let me down. However I never had all these handy ports at my expense. Is the carb stone attachment sold by Spike worth the cost just for oxygenating? How is everyone oxygenating your wort in your CF?

Also, what kinda air pump would y’all suggest if I did grab the carb stone?

I think i will do the carb stone for that reason- so i can carb the tank.

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

I use the carb stone to both aerate and carbonate. I use the red oxygen tanks to aerate. Carbing with the stone is great. It fully carbs your beer *precisely* in 24 hours. It's one of my favorite parts. CheersOk onto OXYGENATING YOUR WORT in Conicals.

For the last several years I’ve simply held my hose really high and let it “splash” it’s way into the fermenter always causing tons of bubbles as it fills up. And that method has never let me down. However I never had all these handy ports at my expense. Is the carb stone attachment sold by Spike worth the cost just for oxygenating? How is everyone oxygenating your wort in your CF?

Also, what kinda air pump would y’all suggest if I did grab the carb stone?

ITV

Well-Known Member

Ok onto OXYGENATING YOUR WORT in Conicals.

For the last several years I’ve simply held my hose really high and let it “splash” it’s way into the fermenter always causing tons of bubbles as it fills up. And that method has never let me down. However I never had all these handy ports at my expense. Is the carb stone attachment sold by Spike worth the cost just for oxygenating? How is everyone oxygenating your wort in your CF?

Also, what kinda air pump would y’all suggest if I did grab the carb stone?

I recently bought the carb stone. I use a 20 cu ft oxygen tank (got tired of spending $10/each for the disposable tanks) to oxygenate and I plan on using it to carbonate with CO2.

Ok onto OXYGENATING YOUR WORT in Conicals.

For the last several years I’ve simply held my hose really high and let it “splash” it’s way into the fermenter always causing tons of bubbles as it fills up. And that method has never let me down. However I never had all these handy ports at my expense. Is the carb stone attachment sold by Spike worth the cost just for oxygenating? How is everyone oxygenating your wort in your CF?

Also, what kinda air pump would y’all suggest if I did grab the carb stone?

However Brülosophy did this experiment in 4 different ways and never found oxygenating the wort to cause any kid of distinguishable difference in the beer:

http://brulosophy.com/2015/05/25/wort-aeration-pt-1-shaken-vs-nothing-exbeeriment-results/

I have the carb stone for my Spike CF10. I've never used it, not for oxygenating, not for carbonation. I have a long O2 wand that I've used, and it seems to work just the same as with my bigmouth bubblers.

Is it worth getting it? Maybe i'll sell you mine?

If you're going to use the carb stone, I'd suggest using oxygen, not an air pump.

And FWIW: you have to be careful with the Brulosophy stuff. Their testing is suspect, i.e., you can't tell when they don't find a difference if there's really no discernable difference, or if everyone doing the tests have their taste buds fried by drinking IPAs or whatever earlier in the evening.

I think Brulosophy is more credible when there is a significant difference, as whatever the test variable, it overcame the limitations in testing. And I have to give them credit for doing some pretty decent experiments, but I don't have much confidence in the "there's no difference" results.

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

I agree on the brulosophy stuffs. Don't take any of it to heart. It all adds up.I have the carb stone for my Spike CF10. I've never used it, not for oxygenating, not for carbonation. I have a long O2 wand that I've used, and it seems to work just the same as with my bigmouth bubblers.

Is it worth getting it? Maybe i'll sell you mine?

If you're going to use the carb stone, I'd suggest using oxygen, not an air pump.

And FWIW: you have to be careful with the Brulosophy stuff. Their testing is suspect, i.e., you can't tell when they don't find a difference if there's really no discernable difference, or if everyone doing the tests have their taste buds fried by drinking IPAs or whatever earlier in the evening.

I think Brulosophy is more credible when there is a significant difference, as whatever the test variable, it overcame the limitations in testing. And I have to give them credit for doing some pretty decent experiments, but I don't have much confidence in the "there's no difference" results.

My aerator is dis ....dis spoon haha. Mix it up good . It foams up good then pitch. Never had an issue one.

If you selling for real i am interested. Pm sent.I have the carb stone for my Spike CF10. I've never used it, not for oxygenating, not for carbonation. I have a long O2 wand that I've used, and it seems to work just the same as with my bigmouth bubblers.

Is it worth getting it? Maybe i'll sell you mine?

If you're going to use the carb stone, I'd suggest using oxygen, not an air pump.

And FWIW: you have to be careful with the Brulosophy stuff. Their testing is suspect, i.e., you can't tell when they don't find a difference if there's really no discernable difference, or if everyone doing the tests have their taste buds fried by drinking IPAs or whatever earlier in the evening.

I think Brulosophy is more credible when there is a significant difference, as whatever the test variable, it overcame the limitations in testing. And I have to give them credit for doing some pretty decent experiments, but I don't have much confidence in the "there's no difference" results.

Stand

Well-Known Member

I have a port on the lid to my kettle, so after cooling I run my chugger pump and shoot a jet of beer down the center of my kettle to oxygenate.

If I let it go more than a minute or two the entire headspace will fill with foam.

I just let it sit in conical for about 10 minutes and then dump the sludge there rather than whirlpooling which never worked that well for me anyway.

If I let it go more than a minute or two the entire headspace will fill with foam.

I just let it sit in conical for about 10 minutes and then dump the sludge there rather than whirlpooling which never worked that well for me anyway.

ZmannR2

Well-Known Member

For everyone that owns a conical do you feel all the extra effort that goes into it is worth the $$? The 20+ parts that goes on it and all the fittings and the cleaning and sanitizing of everything.

I’m coming off a twin set of 5g SS Brewtech Brew buckets and I’m just hoping the extra options I’ll now have like harvesting yeast and pressurized fermention and so on is worth it. Thoughts on your purchase??

I’m coming off a twin set of 5g SS Brewtech Brew buckets and I’m just hoping the extra options I’ll now have like harvesting yeast and pressurized fermention and so on is worth it. Thoughts on your purchase??

ZmannR2

Well-Known Member

I have a port on the lid to my kettle, so after cooling I run my chugger pump and shoot a jet of beer down the center of my kettle to oxygenate.

If I let it go more than a minute or two the entire headspace will fill with foam.

I just let it sit in conical for about 10 minutes and then dump the sludge there rather than whirlpooling which never worked that well for me anyway.

That’s a great idea. I also use a port on my lid to recirculate. Never thought of using it for aeration!

Stand

Well-Known Member

For everyone that owns a conical do you feel all the extra effort that goes into it is worth the $$? The 20+ parts that goes on it and all the fittings and the cleaning and sanitizing of everything.

I’m coming off a twin set of 5g SS Brewtech Brew buckets and I’m just hoping the extra options I’ll now have like harvesting yeast and pressurized fermention and so on is worth it. Thoughts on your purchase??

I'm on my 3rd brew in my CF10, and it's a pain to clean and sanitize all of those pieces for sure. That said, I'd way rather do that than deal with a carboy brush and the 2x 6.5g carboys I was using before. Those things scared the poo out of me.

I'm sure someone here has worked out a better process than me for cleaning, but I just fill a bucket with PBW and throw everything in the bucket. I bought the CIP, but I'm only using it to sanitize. It's just so easy to use a brush, a garden hose and a bucket with some PBW to clean the conical body.

I'd be interested in hearing it if anyone has worked out a good procedure.

For everyone that owns a conical do you feel all the extra effort that goes into it is worth the $$? The 20+ parts that goes on it and all the fittings and the cleaning and sanitizing of everything.

I’m coming off a twin set of 5g SS Brewtech Brew buckets and I’m just hoping the extra options I’ll now have like harvesting yeast and pressurized fermention and so on is worth it. Thoughts on your purchase??

That's a tough question. I've brewed some pretty excellent beer just using my Bigmouth Bubbler fermenters.

I long for the days of simple BIAB and a plastic fermenter.

*********

You have to decide what you're after and whether a conical will serve that purpose for you. My goal has been to brew the best beer possible. I've been exploring low oxygen brewing (LODO) and my Spike CF10 was part of that process. I brew mostly 5-gallon batches, but wanted the ability to do 10-gallon batches if the mood struck.

No doubt about it--it's more involved to clean a fermenter like this. I've never timed it exactly, as I'm not racing to see how fast I can do it, but it's probably an hour to clean it, more or less. I'll dump yeast and trub, and open it up and spray down the inside to get as much gunk out as I can. Like @Stand, I'll take off the valves and such and put them in a tub of hot PBW solution to clean while I work on the body of the fermenter. I'll put a couple of TC caps on the now-exposed ports where I took off the valve, and do a CIP with hot PBW. I let it run for 15 minutes or so (this is why I can't tell you how long it takes) and do some other cleaning/organizing while that is going.

Then I'll switch the hose to the CIP ball to the sink to pump that cleaning solution down the drain, pour some more clean water into the top through the 4" hole, let it rinse, dump to sink, do that again a couple more times. I'll open it up, spray it down on the inside until I'm satisfied it's clean, then using a simple sprayer with Star-San, spray down the inside. I'll reattach the now-clean valves, spray down one more time, and seal it up for the next time.

****

The trick has been...well, learning the tricks to speed things up. I have a sink with a sink sprayer and I can attach a short hose to the faucet so it's easy to spray the thing down. If I didn't have that...well, it would be a pain. Early on, I was recirculating Sani-clean using the CIP ball, which is a low-foam sanitizer. Well, didn't take me long to realize I can A) dunk the temp control coil in a bucket of star-san to sanitize that, and B) spray down everything with Star-San. Faster.

****

So...is it worth it? I've had a LOT of fun with this, figuring things out, making some great beer. And i can do things with this I cannot with a normal plastic fermenter.

I have never harvested yeast from it. I will, eventually. I have...something like 22 fermentations in this now, and it's a very interesting system. I have a closed system, can do oxygen-free pressure transfers to kegs, can self-carbonate (to some degree, I can only achieve about 7psi at serving temp, have to add CO2 to finish it), I even have figured out a way to dry hop and keep oxygen away while doing that.

My whole system is now much more fiddly than it used to be, but that's the nature of that system. I do RIMS control of my mash temps, which is terrific. I can easily do step mashes if I want. But all that is more fiddly, and there's more to clean. Most of that is done during the boil, so it doesn't make the day longer. But there's more. I do electric brewing which I much prefer over propane, but cleanup? More fiddly. I use a counterflow chiller so I need to run cleaning solution through that, and clean the kettle in place. Takes more time, is more fiddly. But it's necessary to use the system I'm using.

Same with the fermenter. If you want the ability to absolutely keep oxygen away from your beer, this will do it.

****

Some pics showing how I manage cleaning issues:

Last edited:

I am 100% happy with my spike cf5 . No regrets.

can self-carbonate (to some degree, I can only achieve about 7psi at serving temp, have to add CO2 to finish it)

Hey @mongoose33 I've heard you mention this a few times and understand the difficulty. You can ferment/spund at 13 PSI at room temperature in the CF10 to get to 1.5 volumes but, when chilled to serving temp this is like carbonating with 7psi and need to make up another volume in the beer after transfering to kegs.

Why not fill those kegs and while still cold and then inject priming sugar with a syringe through the gas in port? Then let them warm back up to room temperature, spund at 29 pSI at 70F for a week and then chill them back down. Prior to adding the priming sugar you could add about 1 gram of rehydrated bottling yeast (something like F-2 or S-04 which will ferment the priming sugar fast, floc completely and stick to the keg bottom). This should get you to a nearly perfectly oxygen free keg with minimal residual yeast.

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

It takes me less than 15 mins hands on to clean my cf15. Cleaning 3 carboys even with the carboy washer was a bigger pain for me. Cheers

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

I'm surprised so few use the carb stone to carb. It makes things alot easier and quicker. It's possibly my favorite part. You do need to be able to get down to 35f min however so not all can do that.That said I'm often dealing with 3 kegs. I like that once I rack to kegs I'm completely done with the correct carbonation rate and can then store at room temperature if needed until I'm ready to tap or give it away. CheersHey @mongoose33 I've heard you mention this a few times and understand the difficulty. You can ferment/spund at 13 PSI at room temperature in the CF10 to get to 1.5 volumes but, when chilled to serving temp this is like carbonating with 7psi and need to make up another volume in the beer after transfering to kegs.

Why not fill those kegs and while still cold and then inject priming sugar with a syringe through the gas in port? Then let them warm back up to room temperature, spund at 29 pSI at 70F for a week and then chill them back down. Prior to adding the priming sugar you could add about 1 gram of rehydrated bottling yeast (something like F-2 or S-04 which will ferment the priming sugar fast, floc completely and stick to the keg bottom). This should get you to a nearly perfectly oxygen free keg with minimal residual yeast.

Hey @mongoose33 I've heard you mention this a few times and understand the difficulty. You can ferment/spund at 13 PSI at room temperature in the CF10 to get to 1.5 volumes but, when chilled to serving temp this is like carbonating with 7psi and need to make up another volume in the beer after transfering to kegs.

Why not fill those kegs and while still cold and then inject priming sugar with a syringe through the gas in port? Then let them warm back up to room temperature, spund at 29 pSI at 70F for a week and then chill them back down. Prior to adding the priming sugar you could add about 1 gram of rehydrated bottling yeast (something like F-2 or S-04 which will ferment the priming sugar fast, floc completely and stick to the keg bottom). This should get you to a nearly perfectly oxygen free keg with minimal residual yeast.

One reason why I've resisted spunding in the keg--I'm spunding in the fermenter, though not at high enough pressure--is the dregs that end up in the keg after spunding.

Probably THE major reason I moved from bottles to kegging was to eliminate the dregs. Finishing in the keg puts a layer of yeast trub at the bottom of the keg and I don't want to draw that up into the beer.

I know there are ways around this, and all are fiddly ways to deal with something that can be addressed by just carbonating w/ CO2. I know that sounds weird coming from someone who's been implementing LODO techniques, but at least at this point, I don't see a lot of degradation due to oxidation from impure CO2.

I even have the ClearBeer system, but I've never used it. Maybe at some point I'll fiddle with that, but for now, it seems to work fairly good as it is.

I just wish Spike had engineered their conicals to handle 20psi.

@ZmannR2 - in a word- YES! It is SO worth it!! The first time I cleaned, sanitized, and put it together, I spent like an hour. I am on my 4th or 5th batch now- and now that I now what goes where, I am down to like 10 mins or so.For everyone that owns a conical do you feel all the extra effort that goes into it is worth the $$? The 20+ parts that goes on it and all the fittings and the cleaning and sanitizing of everything.

I’m coming off a twin set of 5g SS Brewtech Brew buckets and I’m just hoping the extra options I’ll now have like harvesting yeast and pressurized fermention and so on is worth it. Thoughts on your purchase??

If your kitchen sink has a removable spray wand, it is a breeze. I even left it to sit for 4 days after I racked a keg from it. Hot water and PBW (or whatever you use instead of PBW), a little elbow grease, and you are good to go.

+1 to the bucket- drop the parts in, let them soak for 5 mins, use a soft sponge, and rinse.

I have the cf5- so I do not think CIP is even worth it. I can see it for the cf15 or cf30 maybe. Scroll up- you can see us debate this like 2 weeks ago or so.

Probably THE major reason I moved from bottles to kegging was to eliminate the dregs. Finishing in the keg puts a layer of yeast trub at the bottom of the keg and I don't want to draw that up into the beer.

That is why I was suggesting bottling yeast. Bottling yeast is designed to floc completely and stick tightly to the bottom of the vessel. Pitching 1 gram of this yeast fresh at the time of kegging should allow them to outcompete the residual primary yeast and give you a product similar to a properly refermented commercial beer--Sierra Nevada Pale Ale is a prime example of what can be obtained bottle conditioning beer in terms of quantity of yeast in the final package. As far as I know they do not use a special bottling yeast and welcome the slight haze (extremely slight by today's standards) from the residual yeast but others use yeasts such as CBC-1 or F2 which flock hard and stick to the bottom.

I'm going to throw this in here for those looking for ways to integrate pumps into their brewing and cleaning setup.

I use the CIP ball on my conical to clean it. I'd been diddling with my Riptide pump (good pump, that), but it's not that easy to get it all hooked up and such.

Eventually, I mounted it to the front of my brewing bench and it allows me to swap hoses between the BK and the Mash Tun, without a lot of diddling. Even though the Riptide has a switch, it's not that easy nor convenient to operate, especially if one is, well, "in a hurry" if you know what I mean.

I used a normal 2-gang residential switch, wiring each to a separate outlet in the same box, and then the power is supplied from a GFCI outlet.

What I finally figured out today is how to use a smaller Mark II pump and mount it such that it can be fed directly off the bottom of the conical using a 2" barbed TC fitting.

This may give others ideas on how to set up their own area. I have certain space and other limitations that may not be relevant in another context.

This first pic shows how the Mk II pump is set up. I mounted it to a small L-shaped stand, and the power is plugged into the switch setup. I recirculate PBW solution through this for 10 minutes or so after rinsing out the conical and dumping the trub and stuff into a 5-gallon bucket.

Closeup of the pump arrangement. I have camlock connections between the pump and the hoses.

The pump/hose setup for the kettle and mash tun.

The mash tun is to the left just on the edge of the pic. The liquid is recirculated through the counterflow chiller which I use to reduce temp from boiling to strike temperature (I'm pre-boiling strike water to remove oxygen for LODO purposes). Then I take the hose to which the black arrow on the right is pointing, close the kettle valve and use forceps to seal the hose, and move it to the mash tun where the arrow on the left points. The mash tun has a valve and sight glass on it, so that hose will just reach. Thus I can move water from the BK (now cooled to strike temp) to underlet the grain in the mash tun.

Then, when time to pump the wort back to the BK, I take the short hose off the riptide and connect it to the mash tun, and swap the longer hose back to the lower ball valve on the BK.

The red arrow shows the two switches. I just wanted something easier to hit when the time comes. I'll use CO2 to push water, and later, wort, through the system and I need an easy way to control both. This does it

The switch on the left controls the mounted Riptide; the switch on the right controls the Mk II for cleaning the conical.

Hope this gives you all some ideas.

I use the CIP ball on my conical to clean it. I'd been diddling with my Riptide pump (good pump, that), but it's not that easy to get it all hooked up and such.

Eventually, I mounted it to the front of my brewing bench and it allows me to swap hoses between the BK and the Mash Tun, without a lot of diddling. Even though the Riptide has a switch, it's not that easy nor convenient to operate, especially if one is, well, "in a hurry" if you know what I mean.

I used a normal 2-gang residential switch, wiring each to a separate outlet in the same box, and then the power is supplied from a GFCI outlet.

What I finally figured out today is how to use a smaller Mark II pump and mount it such that it can be fed directly off the bottom of the conical using a 2" barbed TC fitting.

This may give others ideas on how to set up their own area. I have certain space and other limitations that may not be relevant in another context.

This first pic shows how the Mk II pump is set up. I mounted it to a small L-shaped stand, and the power is plugged into the switch setup. I recirculate PBW solution through this for 10 minutes or so after rinsing out the conical and dumping the trub and stuff into a 5-gallon bucket.

Closeup of the pump arrangement. I have camlock connections between the pump and the hoses.

The pump/hose setup for the kettle and mash tun.

The mash tun is to the left just on the edge of the pic. The liquid is recirculated through the counterflow chiller which I use to reduce temp from boiling to strike temperature (I'm pre-boiling strike water to remove oxygen for LODO purposes). Then I take the hose to which the black arrow on the right is pointing, close the kettle valve and use forceps to seal the hose, and move it to the mash tun where the arrow on the left points. The mash tun has a valve and sight glass on it, so that hose will just reach. Thus I can move water from the BK (now cooled to strike temp) to underlet the grain in the mash tun.

Then, when time to pump the wort back to the BK, I take the short hose off the riptide and connect it to the mash tun, and swap the longer hose back to the lower ball valve on the BK.

The red arrow shows the two switches. I just wanted something easier to hit when the time comes. I'll use CO2 to push water, and later, wort, through the system and I need an easy way to control both. This does it

The switch on the left controls the mounted Riptide; the switch on the right controls the Mk II for cleaning the conical.

Hope this gives you all some ideas.

Stand

Well-Known Member

I'm surprised so few use the carb stone to carb. It makes things alot easier and quicker. It's possibly my favorite part. You do need to be able to get down to 35f min however so not all can do that.That said I'm often dealing with 3 kegs. I like that once I rack to kegs I'm completely done with the correct carbonation rate and can then store at room temperature if needed until I'm ready to tap or give it away. Cheers

I don't have the carb stone because I bought a spunding valve. I just set it to 15PSI when I get close to the end of fermentation. I set my regulator to around 10PSI during cold-crash since I'm going to take it down to 32 degrees. By the time I'm done I am ready to keg I am very close to the right carbonation.

If all that doesn't get me where I want to be I'll burst carbonate. It's cool, but it's a neat solution to a problem I don't have.

Now if I made high gravity beers it would be a great way to deliver O2, but I don't.

Similar threads

- Replies

- 2

- Views

- 730

- Replies

- 26

- Views

- 597

- Replies

- 1

- Views

- 377