kokonutz

Well-Known Member

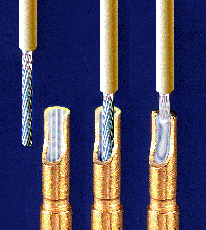

Hi - I have this thermocouple (image below...2 blue, one red) - I was reading this post and realize I need some more clarity. Both my XLR female connector and male receptacle have labels 1,2, and 3 respectively for each prong. My plan is/was:

- snip off red, blue and blue connectors

- solder newly snipped wires to female XLR connector (see question below)

- solder 3 wires onto a male receptical that leads to the PID