I put this guide together to provide additional context for some of my recommendations when people contact me and ask advice on their single vessel brewing systems. I sell a custom system that employs these recommendations but the advice is just as relevant to owners of other brand name systems. I have run extensive trials with remote probe thermometers placed in various positions within the test brewing systems to back up the claims made about stratification and heat loss.

Questions and debate welcomed...

I'm just pasting all the text here to make it easier to search and quote since the above slides are pictures.

Single Vessel Brewing Systems

mash temp stability and homogeneity

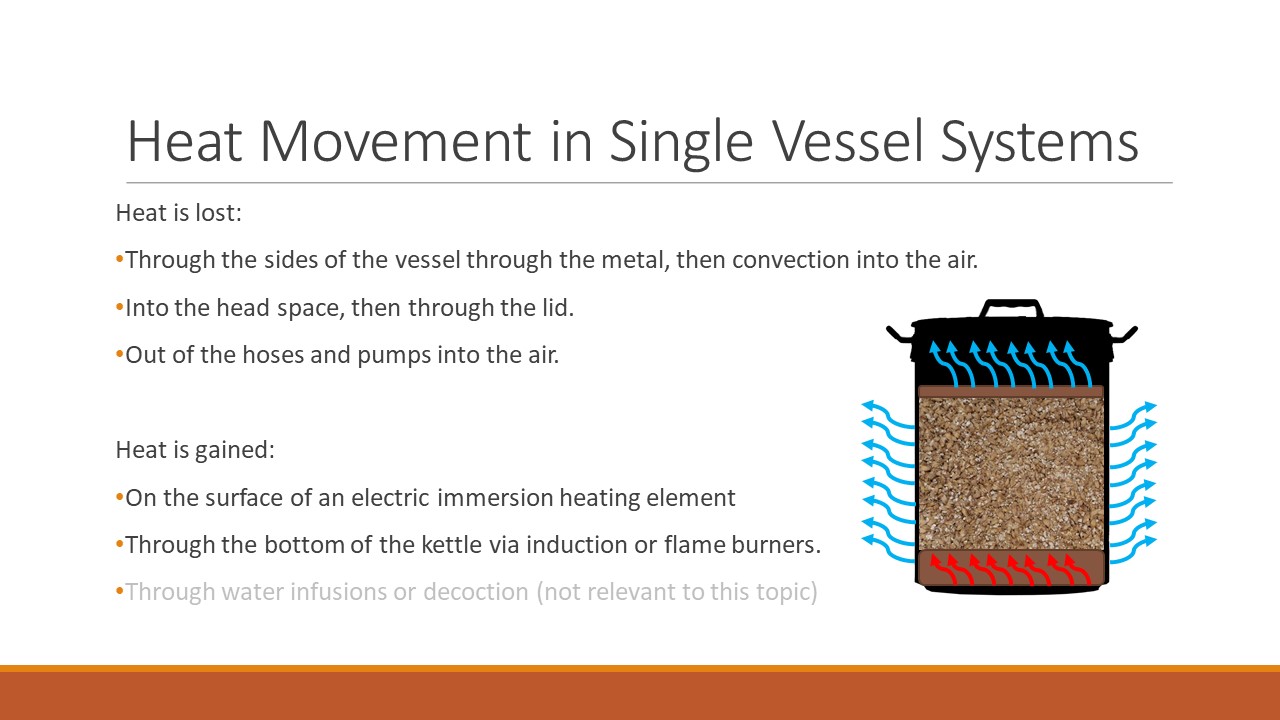

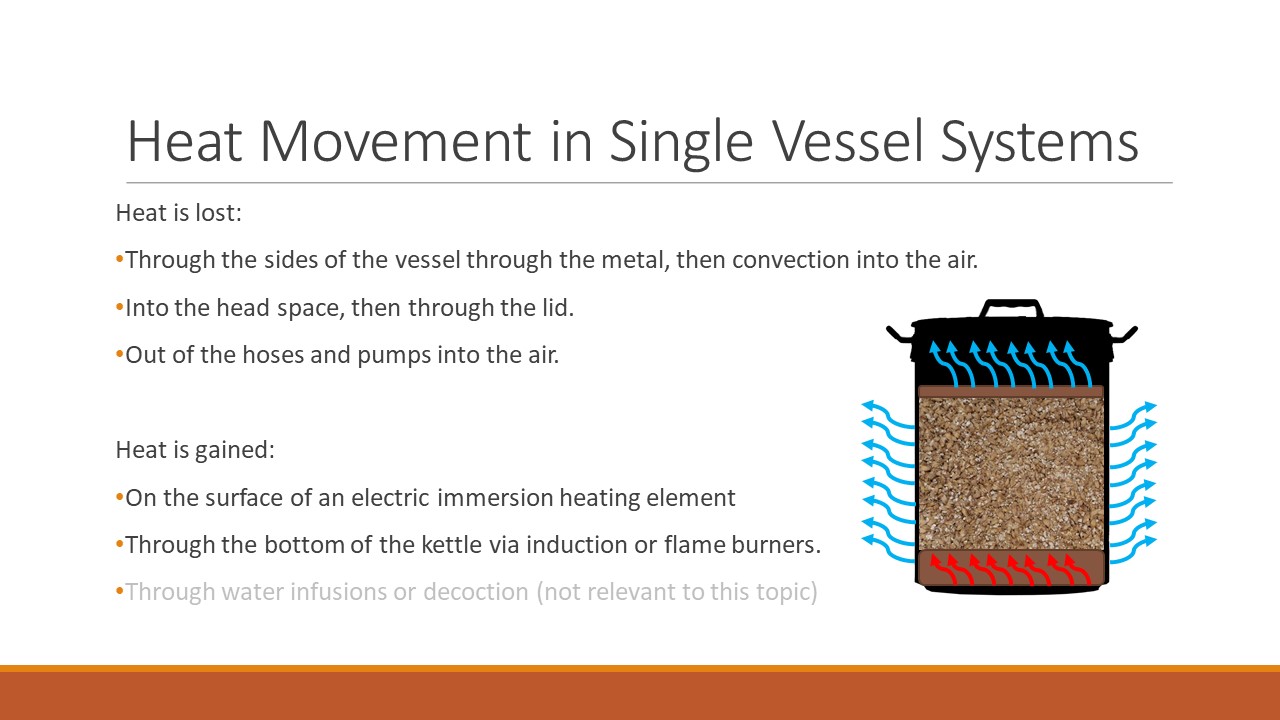

Heat Movement in Single Vessel Systems

Heat is lost:

•Through the sides of the vessel through the metal, then convection into the air.

•Into the head space, then through the lid.

•Out of the hoses and pumps into the air.

Heat is gained:

•On the surface of an electric immersion heating element

•Through the bottom of the kettle via induction or flame burners.

•Through water infusions or decoction (not relevant to this topic)

Does it matter?

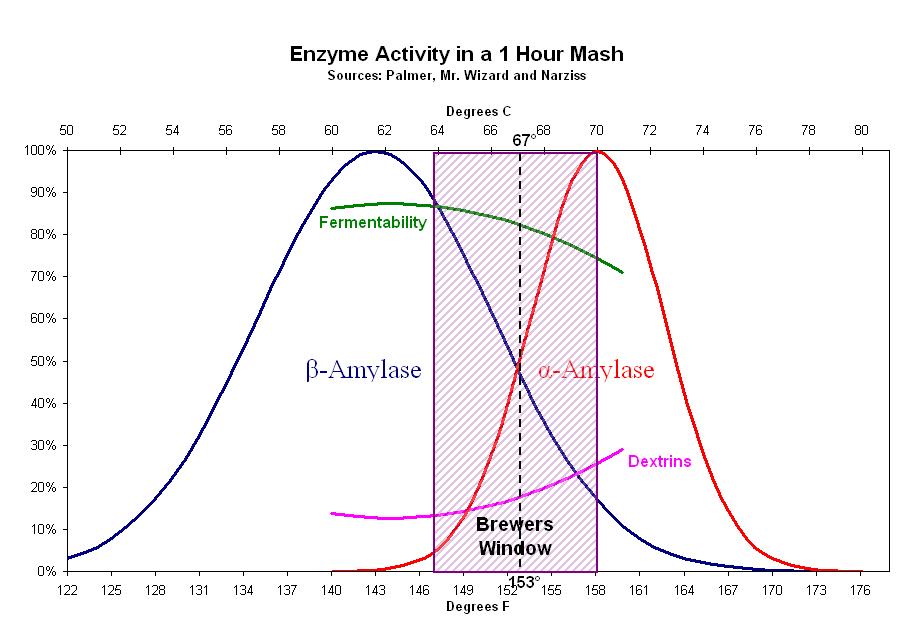

§Pockets of colder mash convert slower and make a different sugar than the recipe intended.

§You may never know what your effective or average mash temperature was, which makes recipe communication and repeatability difficult.

§Step mashing via direct heat input will require that heat to be distributed to make the step schedule effective and repeatable.

§Whether any of this matters is based on your desired level of precision and consistency in your own brewing. That is to say, a mash with wide variation in temperatures and lack of precision will almost always make wort for better or worse.

Combating Heat Instability

§Insulation (helps in cold ambient brewing environments)

§Active heating while the mash progresses

§Distributing newly heated wort to areas where heat is lost via:

◦Occasional stirring, or

◦Constant recirculation from the heated area to the top of the mash

◦Whirlpooling (stirring) Deadspace Wort

◦A combination of the aboveam Jacketing is typically done on larger commercial systems to add heat to a large surface area but is impractical on a homebrew scale.

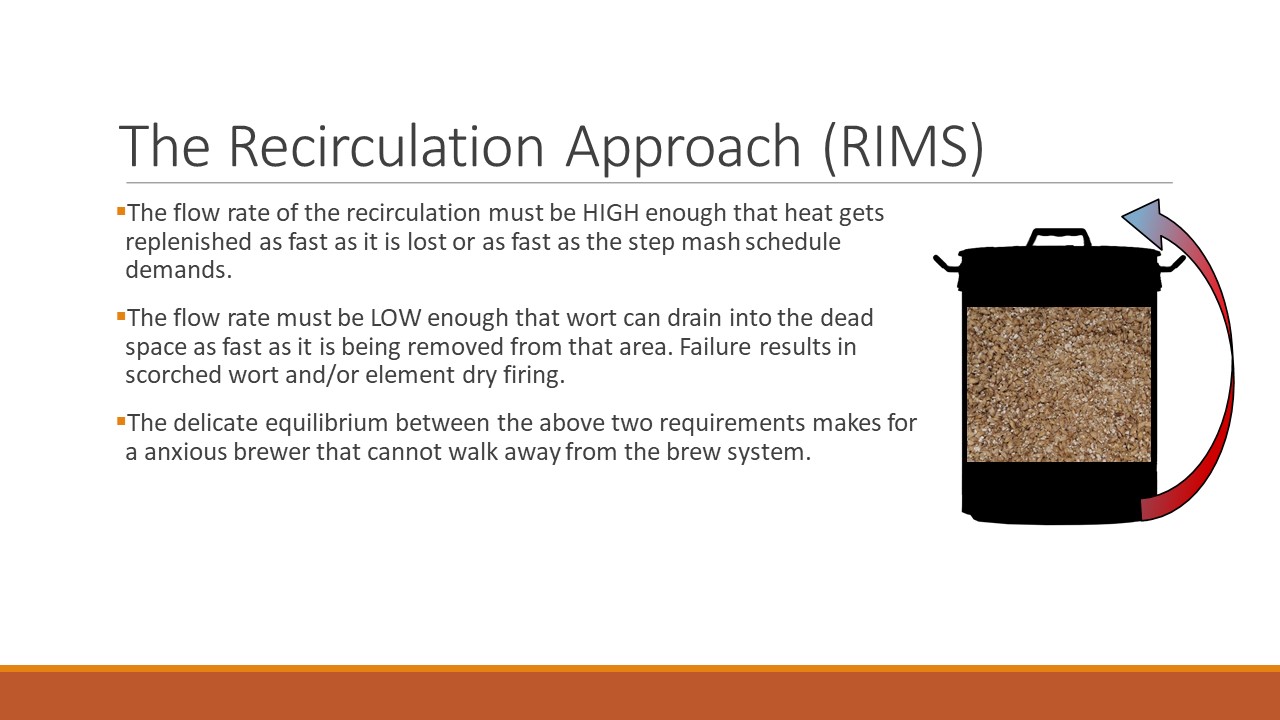

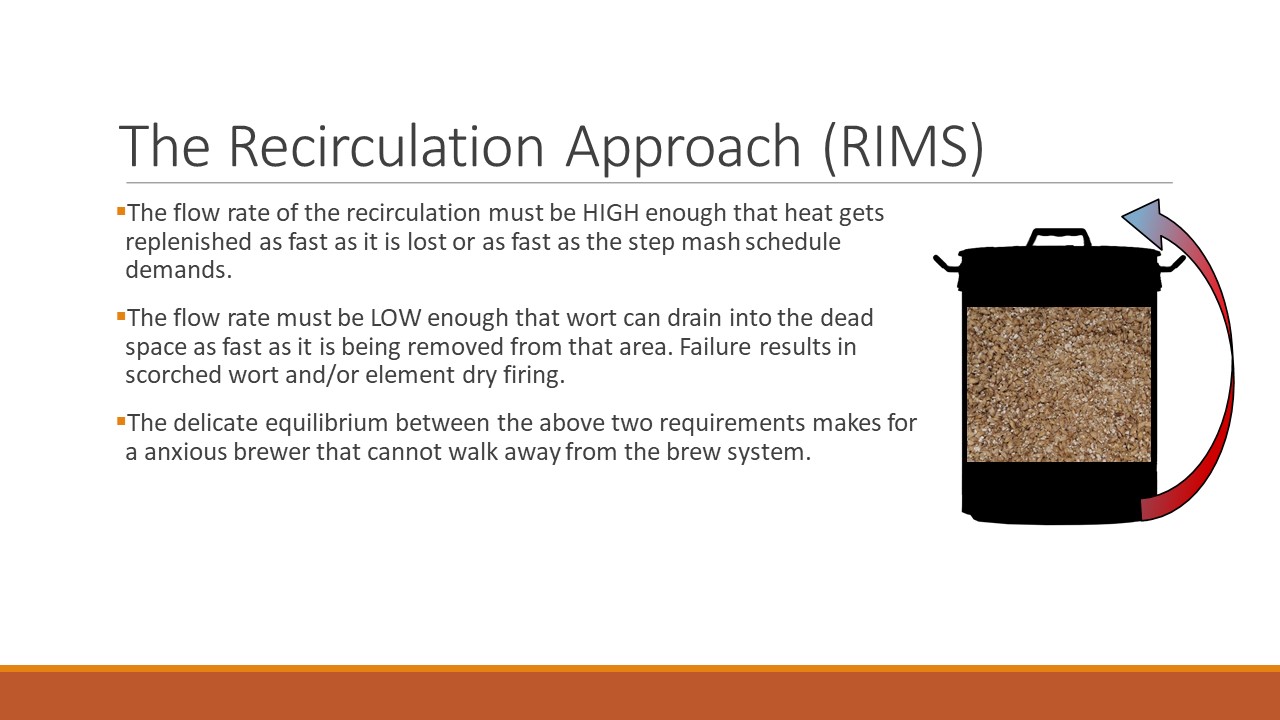

The Recirculation Approach (RIMS)

§The flow rate of the recirculation must be HIGH enough that heat gets replenished as fast as it is lost or as fast as the step mash schedule demands.

§The flow rate must be LOW enough that wort can drain into the dead space as fast as it is being removed from that area. Failure results in scorched wort and/or element dry firing.

§The delicate equilibrium between the above two requirements makes for a anxious brewer that cannot walk away from the brew system.

Constant Stirring

§An overhead view shows the stratification between the heat input (element) and the sensor location if the area below the mash is left static.

§Some Heat will migrate towards the drain if a pump is drawing.

§Without stirring this lower area:

§The sensor (and controller) will never know the true average temperature of the wort due to the stratification.

§During longer heating cycles, such as step mashing, the wort nearest the element will be overheated contributing to enzyme denaturing and unnecessary caramelization (potentially even scorching).

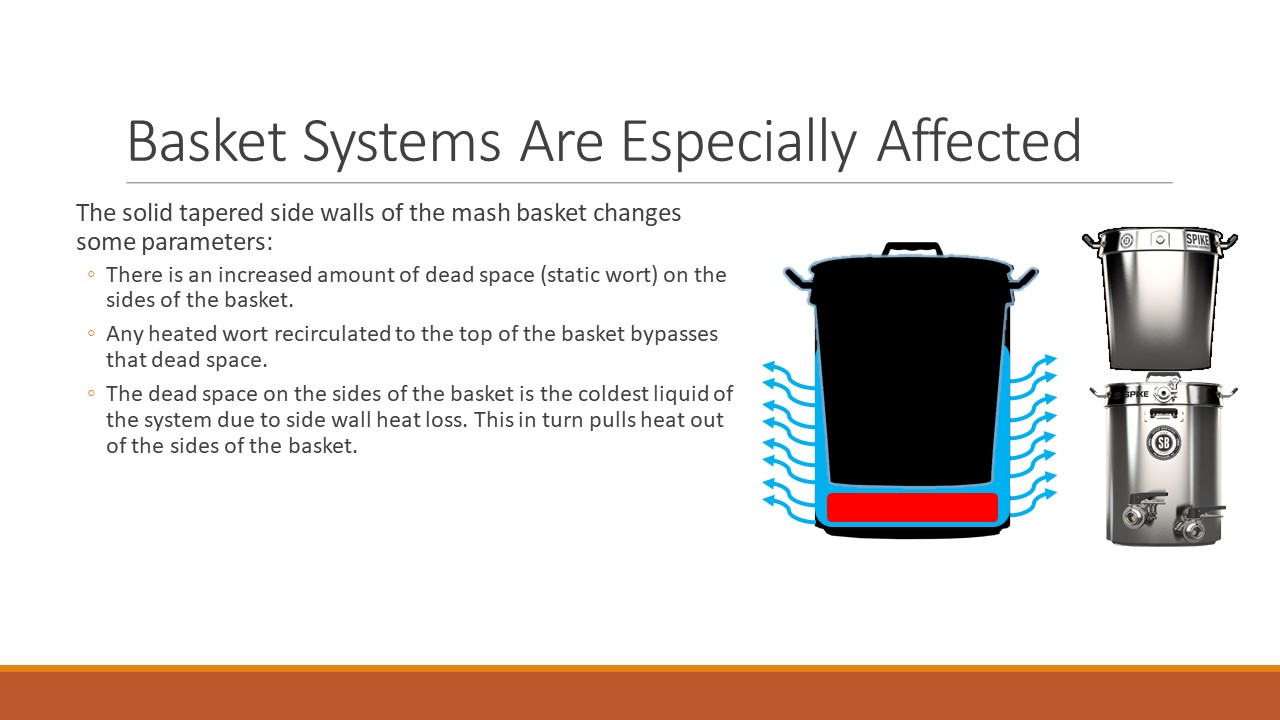

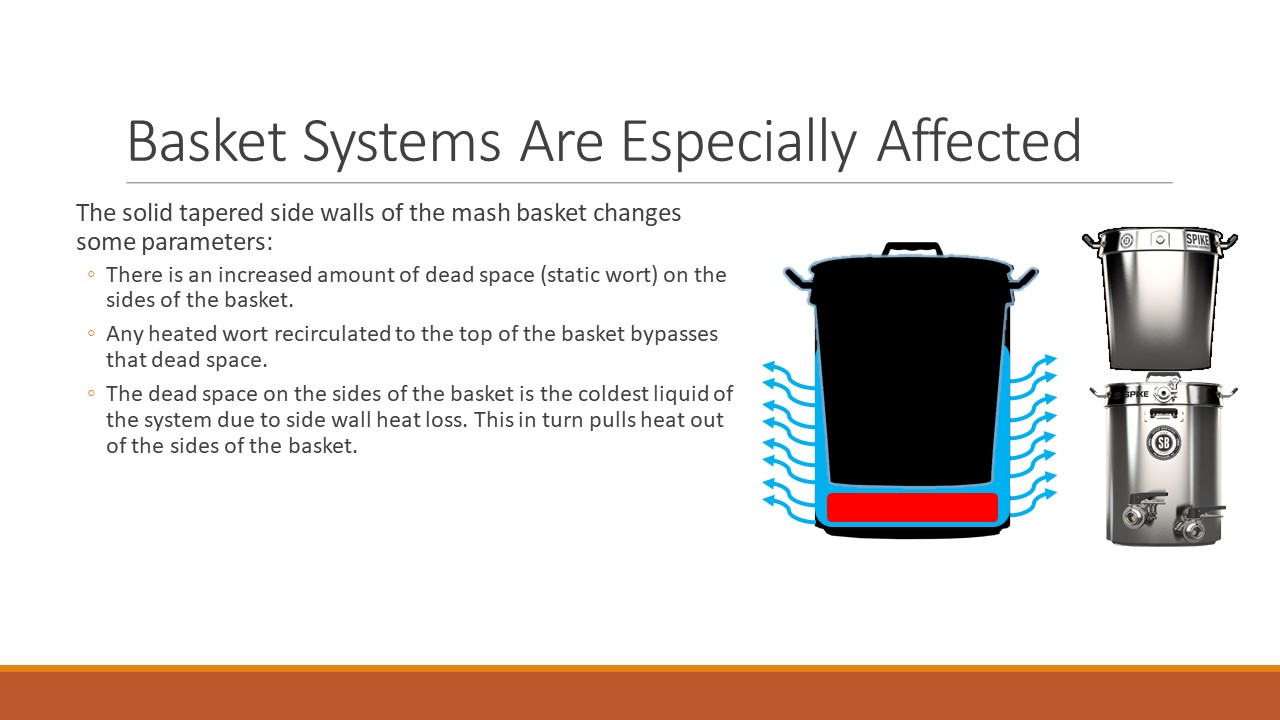

Basket Systems Are Especially Affected

The solid tapered side walls of the mash basket changes some parameters:

◦There is an increased amount of dead space (static wort) on the sides of the basket.

◦Any heated wort recirculated to the top of the basket bypasses that dead space.

◦The dead space on the sides of the basket is the coldest liquid of the system due to side wall heat loss. This in turn pulls heat out of the sides of the basket.

◦

The Recommended Solution

Splitting the pump output and sending heated wort to both the whirlpool port and the top of the mash fixes several problems.

◦The flow to the whirlpool stirs the entire dead space and if the arm is tilted up it will exchange the wort trapped on the sides of the basket. The result is better temp stability overall. The reduces the need for a very fast mash recirculation flow.

◦The flow to the whirlpool port acts as a pump bypass and allows for a much finer control of the mash recirculation flow rate, which should be 1 to 2 liters per minute to avoid dry firing the element upon a stuck mash drainage.

How the split is physically achieved is very system dependent but the main requirement is that each of the flows can be completely shut off or throttled to any flow rate. The whirlpool port will usually already have a valve in place.

Questions and debate welcomed...

I'm just pasting all the text here to make it easier to search and quote since the above slides are pictures.

Single Vessel Brewing Systems

mash temp stability and homogeneity

Heat Movement in Single Vessel Systems

Heat is lost:

•Through the sides of the vessel through the metal, then convection into the air.

•Into the head space, then through the lid.

•Out of the hoses and pumps into the air.

Heat is gained:

•On the surface of an electric immersion heating element

•Through the bottom of the kettle via induction or flame burners.

•Through water infusions or decoction (not relevant to this topic)

Does it matter?

§Pockets of colder mash convert slower and make a different sugar than the recipe intended.

§You may never know what your effective or average mash temperature was, which makes recipe communication and repeatability difficult.

§Step mashing via direct heat input will require that heat to be distributed to make the step schedule effective and repeatable.

§Whether any of this matters is based on your desired level of precision and consistency in your own brewing. That is to say, a mash with wide variation in temperatures and lack of precision will almost always make wort for better or worse.

Combating Heat Instability

§Insulation (helps in cold ambient brewing environments)

§Active heating while the mash progresses

§Distributing newly heated wort to areas where heat is lost via:

◦Occasional stirring, or

◦Constant recirculation from the heated area to the top of the mash

◦Whirlpooling (stirring) Deadspace Wort

◦A combination of the aboveam Jacketing is typically done on larger commercial systems to add heat to a large surface area but is impractical on a homebrew scale.

The Recirculation Approach (RIMS)

§The flow rate of the recirculation must be HIGH enough that heat gets replenished as fast as it is lost or as fast as the step mash schedule demands.

§The flow rate must be LOW enough that wort can drain into the dead space as fast as it is being removed from that area. Failure results in scorched wort and/or element dry firing.

§The delicate equilibrium between the above two requirements makes for a anxious brewer that cannot walk away from the brew system.

Constant Stirring

§An overhead view shows the stratification between the heat input (element) and the sensor location if the area below the mash is left static.

§Some Heat will migrate towards the drain if a pump is drawing.

§Without stirring this lower area:

§The sensor (and controller) will never know the true average temperature of the wort due to the stratification.

§During longer heating cycles, such as step mashing, the wort nearest the element will be overheated contributing to enzyme denaturing and unnecessary caramelization (potentially even scorching).

Basket Systems Are Especially Affected

The solid tapered side walls of the mash basket changes some parameters:

◦There is an increased amount of dead space (static wort) on the sides of the basket.

◦Any heated wort recirculated to the top of the basket bypasses that dead space.

◦The dead space on the sides of the basket is the coldest liquid of the system due to side wall heat loss. This in turn pulls heat out of the sides of the basket.

◦

The Recommended Solution

Splitting the pump output and sending heated wort to both the whirlpool port and the top of the mash fixes several problems.

◦The flow to the whirlpool stirs the entire dead space and if the arm is tilted up it will exchange the wort trapped on the sides of the basket. The result is better temp stability overall. The reduces the need for a very fast mash recirculation flow.

◦The flow to the whirlpool port acts as a pump bypass and allows for a much finer control of the mash recirculation flow rate, which should be 1 to 2 liters per minute to avoid dry firing the element upon a stuck mash drainage.

How the split is physically achieved is very system dependent but the main requirement is that each of the flows can be completely shut off or throttled to any flow rate. The whirlpool port will usually already have a valve in place.