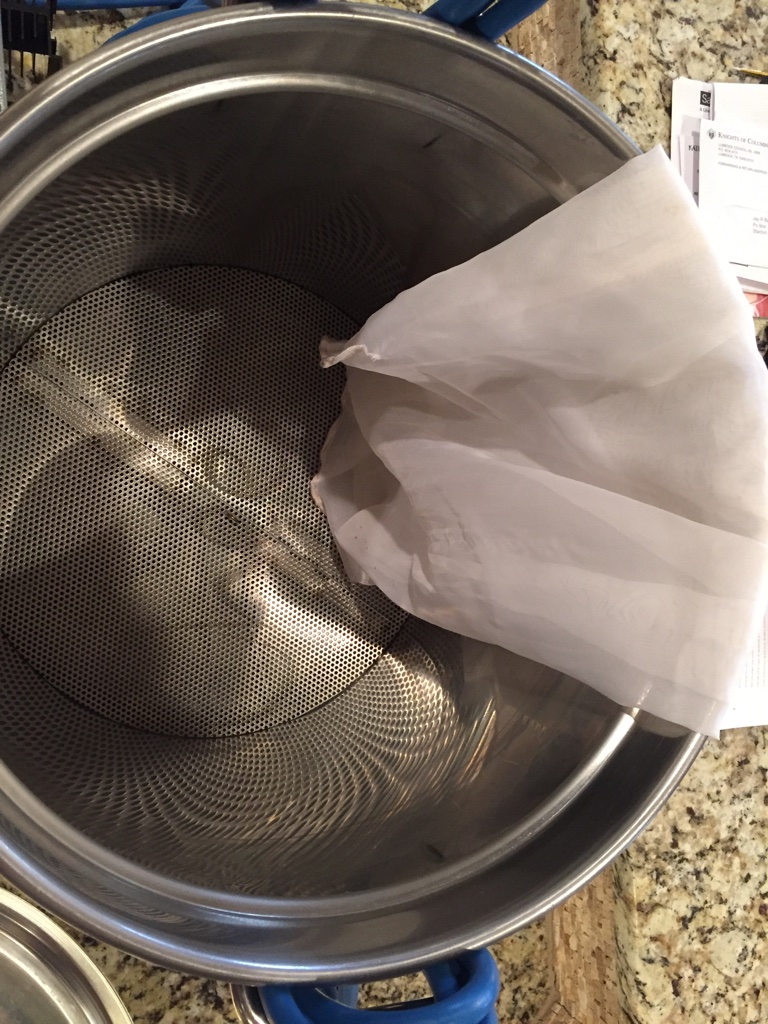

I'm building a basket... I work in a fabrication shop. The issue I had with traditional voile bags was even in my steam basket with feet, if I ran the pump it clogged the bag and turned it into a waterballoon. I eventually had to switch to a more course material similar to a paint strainer bag, but I get a bunch more drain matter in my wort then I would like. Just wondering how the baskets prevail.

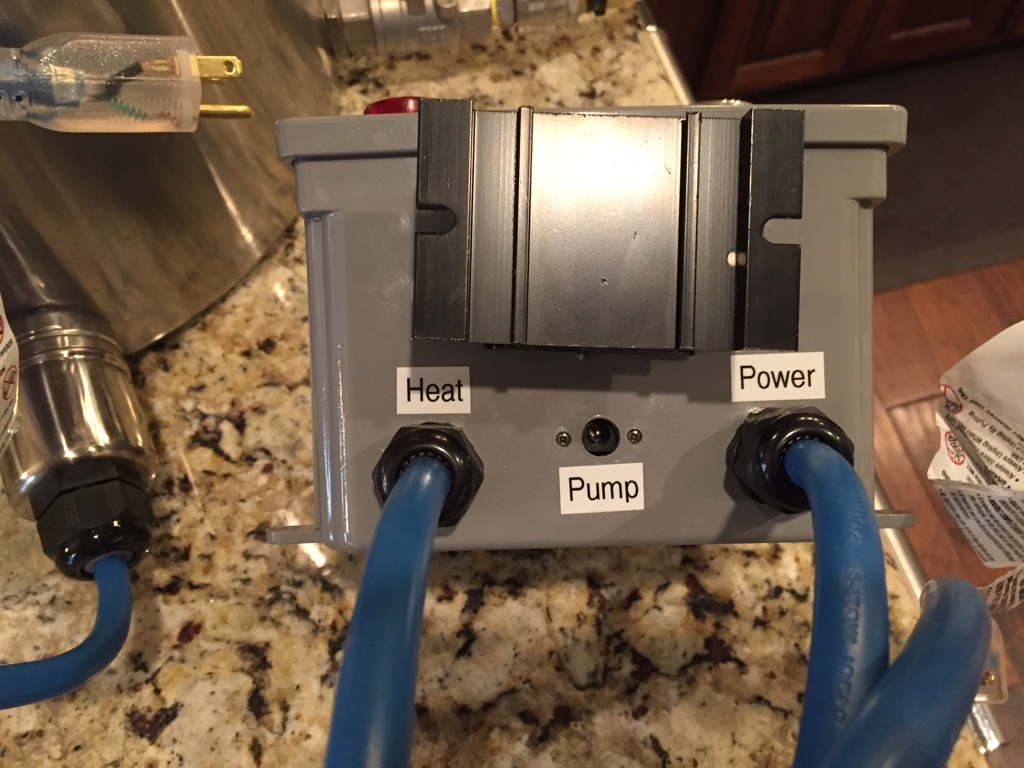

Hmmm, I use a Wilser bag with my BB system/false bottom and never had it completely clog. On my very first brew with it, a Rye PA it did pull with enough force to dent the bottom of the kettle where the four silicone feet for the false bottom were, but I never lost flow or pumped it dry. The pump output was throttled back about half.

I'm reasonably certain that the COFI filters are 800 micron, so keep that in mind when comparing notes.