I am always fascinated by the innovations that Bobby comes up with. Most of you know similar products have been done before, but I think there are probably even more ideas waiting to be "tapped." I'm not sure there is enough room on the TC plate, but if you were to put a few of these on there: http://www.chicompany.net/index.php?main_page=product_info&cPath=376_1_3_260&products_id=3276, I could see people interested in an easy way to convert to ball lock without using a tall sanke coupler + expensive fittings and such. Obviously you would need to find room for a prv as well. You could maybe even use that setup as the racking cane and blow off by hooking up ball lock disconnects to it, then hooking up co2 to transfer. The idea isn't necessarily fleshed out to its entirety with benefits/pitfalls, but thought I might throw it out there. There are a lot of creative people here and someone might be able to build upon it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sanke Fermenter Prototypes

- Thread starter Bobby_M

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Photopilot

Well-Known Member

I'm not sure there is enough room on the TC plate, but if you were to put a few of these on there: http://www.chicompany.net/index.php?main_page=product_info&cPath=376_1_3_260&products_id=3276, I could see people interested in an easy way to convert to ball lock without using a tall sanke coupler + expensive fittings and such. Obviously you would need to find room for a prv as well.

The beauty of this setup is you don't need to add a thing to the TC. By adding a T-Fitting cross to the male thread of this cap, you have the option to add 2-3 different fittings on to this unit. The same unit could be used to make a pressure fermenter vessel and then be used to debe beer from a sanke, without the need of a sanke coupler.

Sure, mine are bore-thru as well. I just realized the page didn't say anything about it so I just added a note:

http://brewhardware.com/fittings-75/103-tubecompression

Excellent news -I was wondering why you didnt have those... Gald I could help.

The beauty of this setup is you don't need to add a thing to the TC. By adding a T-Fitting cross to the male thread of this cap, you have the option to add 2-3 different fittings on to this unit. The same unit could be used to make a pressure fermenter vessel and then be used to debe beer from a sanke, without the need of a sanke coupler.

Bingo - that is what makes it such a great piece. The flexibility.

The only problem with it so far is that you have to watch and test many more areas for pressure leaks... patience and water testing are necessary here.

I do agree that this is a very flexible setup, but by the time you get all the extra fittings and parts, it isn't much of a savings compared to the competing product, and is a much bulkier design. With that said, I do see some very compelling qualities. Any idea if you were to attach the cross/tee fitting using a camlock, the cane would still be able to fit freely? I would personally rather not have it connected at all times if you could just swap out the blow off and pop the assembly on in a matter of seconds. This would also mean you could have one racking attachment for use of multiple fermenters. This would really peek my interest as the price per fermenter would go down considerably if you didn't have redundant equipment. It also makes it less tall which is another big bonus.

And before anyone points it out, yes I realize the weld in corny post idea wouldn't be that cheap in the end once you factor in everything needed, but I thought maybe someone else would be inspired with other uses and setups.

I'm trying to rationalize going this route over my current setup of the rubber carboy caps, but it might be a little while before I decide to appropriate money for this upgrade. My want list has a waiting list!

And before anyone points it out, yes I realize the weld in corny post idea wouldn't be that cheap in the end once you factor in everything needed, but I thought maybe someone else would be inspired with other uses and setups.

I'm trying to rationalize going this route over my current setup of the rubber carboy caps, but it might be a little while before I decide to appropriate money for this upgrade. My want list has a waiting list!

Is there enough room on the cap to drill a hole for corny style pressure safety?

I'd love to be able to put a ball valve on the threaded part and still have a diptube. I wonder if there is room for welded liquid corny post as well?

Or perhaps there is a good way to cap off a racking cane for pressure ferment?

I'd love to be able to put a ball valve on the threaded part and still have a diptube. I wonder if there is room for welded liquid corny post as well?

Or perhaps there is a good way to cap off a racking cane for pressure ferment?

Is there enough room on the cap to drill a hole for corny style pressure safety?

I'd love to be able to put a ball valve on the threaded part and still have a diptube. I wonder if there is room for welded liquid corny post as well?

Or perhaps there is a good way to cap off a racking cane for pressure ferment?

you just need to add a threaded tee or cross to add more flexibility and options.

I could add the pressure relief that way.

I guess my main concern is with pressure fermenting. I would like to leave the diptube in while fermenting to %100 avoid air exposure. If it doesn't hold (let's say it accidentally creeps to 70 psi ) I don't want the diptube to leak and allow the whole keg (12 gallons) to squirt out through the diptube onto the floor.

I like the looks of the way Maierhof did it (post #9), but would just like to hear If Bobby had any kit plans for welded corny posts.

I don't know the psi rating of compression fittings. Swagelok seems to mention 15000 psi which seems high to me. And what if I constantly loosen and re-tighten the fitting to adjust dip tube length to accommodate trub level or use keg for serving?

I guess my main concern is with pressure fermenting. I would like to leave the diptube in while fermenting to %100 avoid air exposure. If it doesn't hold (let's say it accidentally creeps to 70 psi ) I don't want the diptube to leak and allow the whole keg (12 gallons) to squirt out through the diptube onto the floor.

I like the looks of the way Maierhof did it (post #9), but would just like to hear If Bobby had any kit plans for welded corny posts.

I don't know the psi rating of compression fittings. Swagelok seems to mention 15000 psi which seems high to me. And what if I constantly loosen and re-tighten the fitting to adjust dip tube length to accommodate trub level or use keg for serving?

Awesome stuff there BobbyM. I'm awaiting my garage to be cleaned to reach my equipment and start brewing again. It's been awhile now but, I'm going to precision machining school and making gadgets is all I've been thinking about while attending. Great work! I can't believe keg fermenting has grown the way it has and my little thread is still going as well. I love this forum and how ideas expand into things like this. Keep it up guys, and BobbyM... you fricken rock dude.

Sent from my iPhone using Home Brew

Sent from my iPhone using Home Brew

srice

Well-Known Member

- Joined

- Oct 21, 2012

- Messages

- 262

- Reaction score

- 58

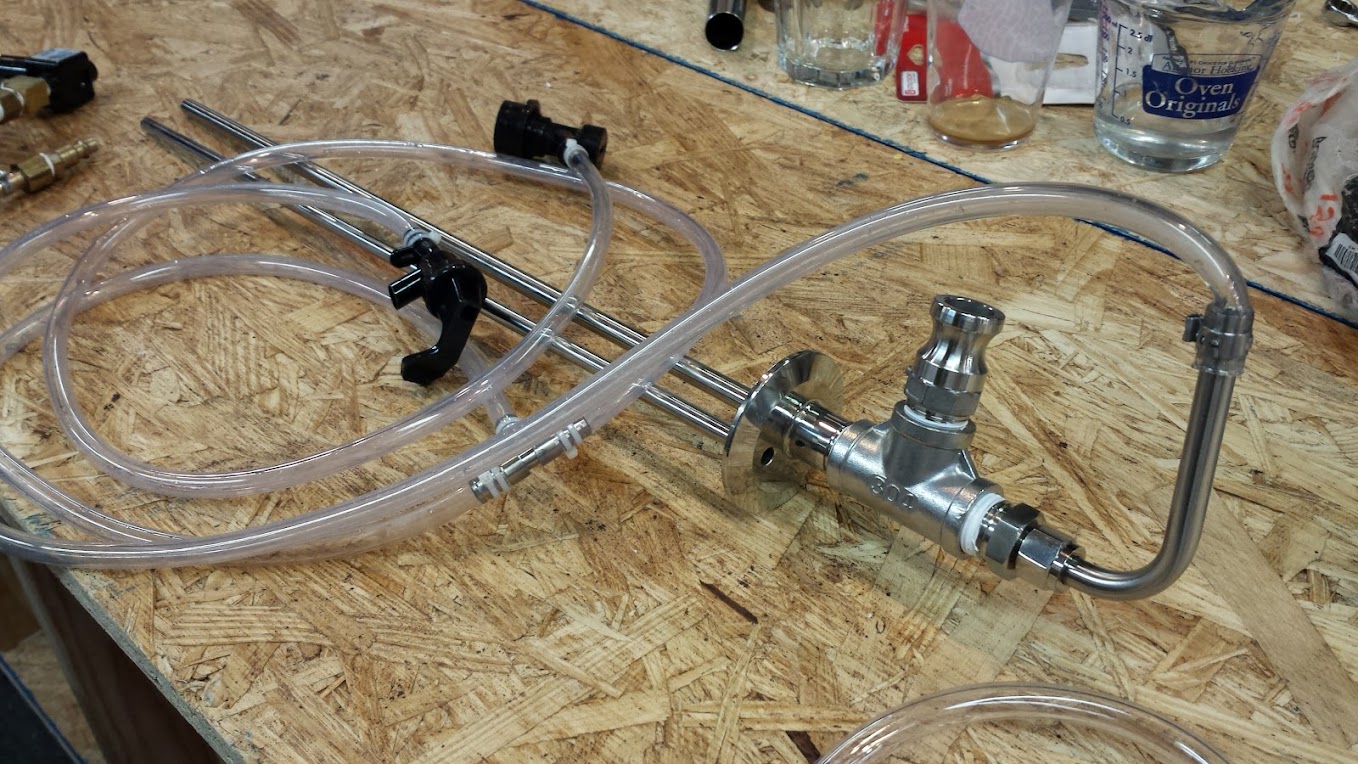

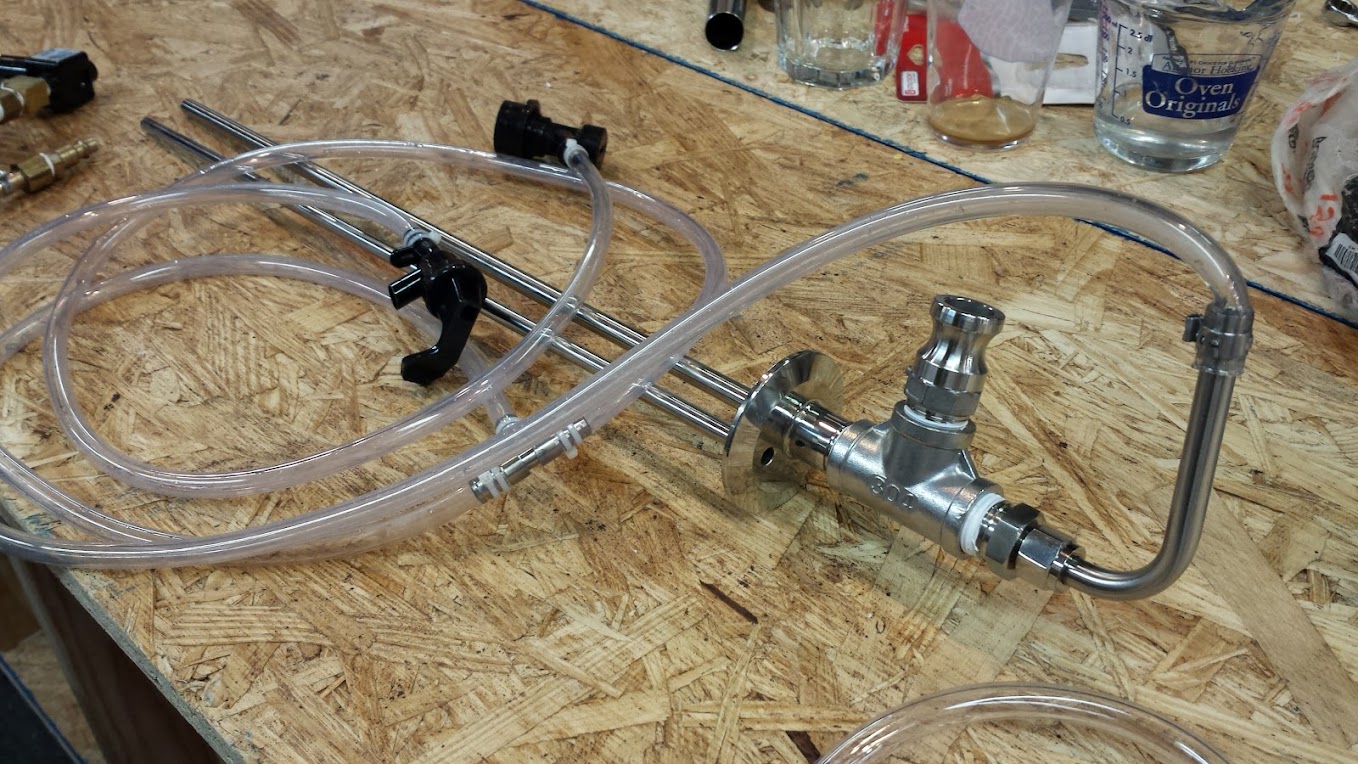

Thanks to Bobby and Wortmomger I am pretty close to finishing my closed pressure fermentation using a Sanke. Need to order a SS ball valve and put my liquid corny post on it and it's complete. Thanks to both of you!

View attachment 202327View attachment 202328

Sent from my iPhone using Home Brew

What size (OD) is that racking cane and are you going to just use a 1/2" MPT to corny post thread adapter to a liquid post on the output of the valve?

3/8" (I had a couple in stock here) and yes, I still need to change the brass ball valve to a SS for consistency and do the same thing that I did with the gas QD.

haeffnkr

Well-Known Member

Hello All,

I have been pressure fermenting in Sankes for a while now.

I have been using the sanke spear and couplers and even though I believe I have all the hardware clean I am still getting some funkiness/infections in some of my beer and want to try one of these sanke kits to simplify the hardware and make sure there are no nasties hiding in the spear/coupler/etc.

So... with all the gas and liquid side hardware hanging off some of these very cool setups, how do you clean these once the beer is transferred into serving kegs?

You have to pull all the gas side fittings off and dis assemble it all after every ferment or?

Edit -

I guess after looking at this again... assuming ample headspace in the keg, the only thing touching the beer is the racking cane and the thermowell.... so a quick cleaning and spritz with starsan on the outside and a line brush/pbw blast with pressure and starsan on the inside of the racking cane and it should be clean?

Do you all use clean these in place with the keg and use the keg cleaning solution also?

thanks Kevin

I have been pressure fermenting in Sankes for a while now.

I have been using the sanke spear and couplers and even though I believe I have all the hardware clean I am still getting some funkiness/infections in some of my beer and want to try one of these sanke kits to simplify the hardware and make sure there are no nasties hiding in the spear/coupler/etc.

So... with all the gas and liquid side hardware hanging off some of these very cool setups, how do you clean these once the beer is transferred into serving kegs?

You have to pull all the gas side fittings off and dis assemble it all after every ferment or?

Edit -

I guess after looking at this again... assuming ample headspace in the keg, the only thing touching the beer is the racking cane and the thermowell.... so a quick cleaning and spritz with starsan on the outside and a line brush/pbw blast with pressure and starsan on the inside of the racking cane and it should be clean?

Do you all use clean these in place with the keg and use the keg cleaning solution also?

thanks Kevin

I'm still learning to tig weld so I haven't pressure fermented yet. Though I would wash everything. The vapor leaving the fermentation vent is bound to have some degree of wort attached.

My plan to clean once ready would be

1.) 2-3 day oxiclean soak, this would be filling the keg right to the brim and also submerging the other parts, except the pressure gauge and pressure valve, perhaps these can be lightly misted with star san spray bottle?

2. rinse everything out and then cip recirc a fresh batch of heated oxy-clean using a keg wash style pump for an hour. flush with water, then flush with star san.

Maybe get a mirror and flashlight to do an inspection the first couple times cleaning.

My plan to clean once ready would be

1.) 2-3 day oxiclean soak, this would be filling the keg right to the brim and also submerging the other parts, except the pressure gauge and pressure valve, perhaps these can be lightly misted with star san spray bottle?

2. rinse everything out and then cip recirc a fresh batch of heated oxy-clean using a keg wash style pump for an hour. flush with water, then flush with star san.

Maybe get a mirror and flashlight to do an inspection the first couple times cleaning.

haeffnkr

Well-Known Member

I am thinking about using a tee with a compression/racking cane and the middle tee port would have a cam lock male fitting with this sanke setup.

With a barbed female camlock fitting I would have a gas side hose and my spunding valve.

For cleaning -

Pull off the camlock and gas side then soak/spray/wash it all up, sanitize and ready for the next batch.

thoughts?

thanks Kevin

With a barbed female camlock fitting I would have a gas side hose and my spunding valve.

For cleaning -

Pull off the camlock and gas side then soak/spray/wash it all up, sanitize and ready for the next batch.

thoughts?

thanks Kevin

Awesome thread. Thanks to all for the never ending ideas and things to make/get.

30Bones

Well-Known Member

I really wish I had kept one of my old 1/2 barrel kegs as I am now doing more and more 10 gallon batches and this would be a nice space saver on top of being super trick!

haeffnkr

Well-Known Member

Hello,

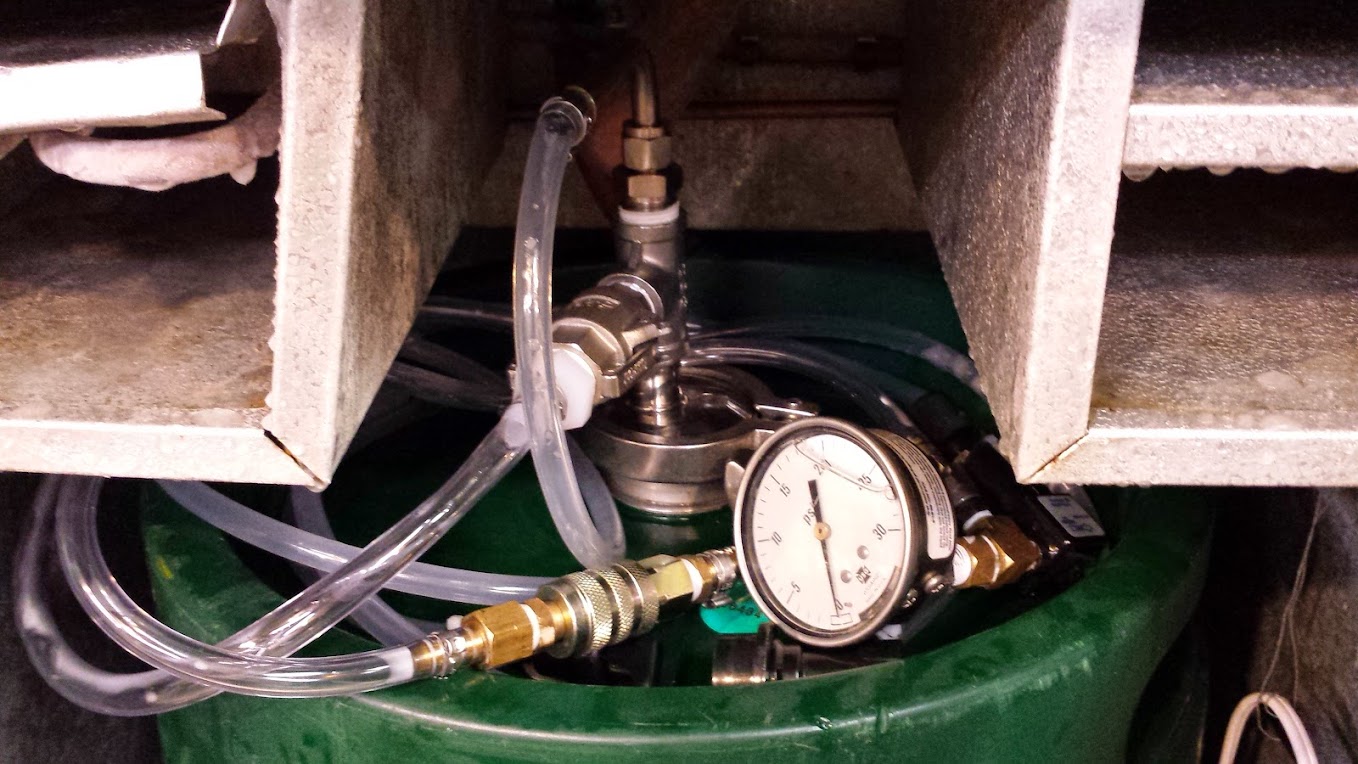

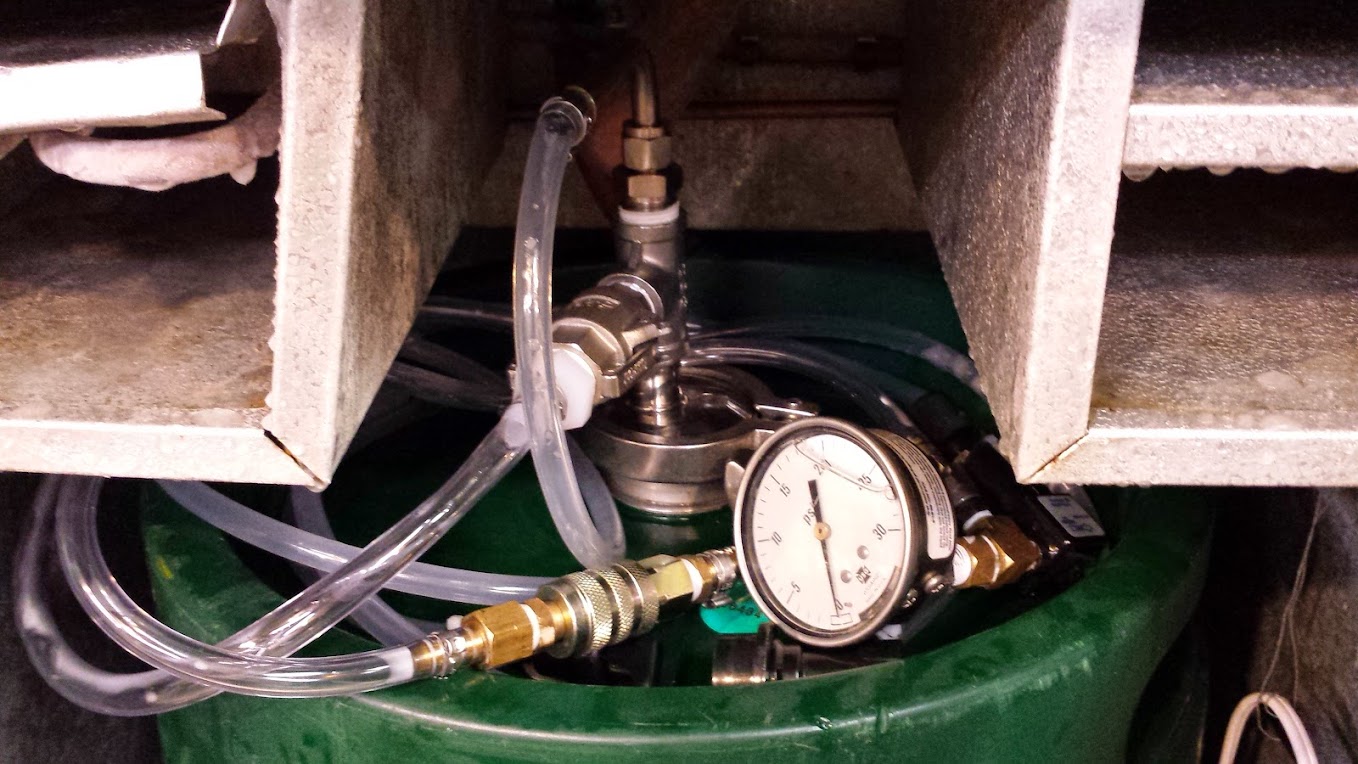

Thanks to you all I came up with my "coupler" design.

I will let you know how it works, this morning it was holding at 5 pounds.

Also - the first time I used the thermowell, I did not have to get tape to stick to the cold wet sides of the keg, It was worth the added expense to get the units from Bobby_M.

It was awesome.

Thanks again for all the tips and pics.

Comments welcome

Kevin

Thanks to you all I came up with my "coupler" design.

I will let you know how it works, this morning it was holding at 5 pounds.

Also - the first time I used the thermowell, I did not have to get tape to stick to the cold wet sides of the keg, It was worth the added expense to get the units from Bobby_M.

It was awesome.

Thanks again for all the tips and pics.

Comments welcome

Kevin

haeffnkr

Well-Known Member

How many PSI have people been getting when using the orings and/or the delrin compression fittings?

I have only seen about 8 psi, not sure if I missed the window and my yeast is done or if I have a leak at the compression fitting.

thanks Kevin

I have only seen about 8 psi, not sure if I missed the window and my yeast is done or if I have a leak at the compression fitting.

thanks Kevin

Since this app wont let me add photos to private msgs - here you go haff (sp)

The first is with the cap on, the second is with the cap off.

It is basically a spare piece of ss (hammered shut then silver soldered closed) I use a ss washer on the full bore compression top to my piece as a I never could hold any pressure for long term via the delrin or orings.

Hope this helps!

The first is with the cap on, the second is with the cap off.

It is basically a spare piece of ss (hammered shut then silver soldered closed) I use a ss washer on the full bore compression top to my piece as a I never could hold any pressure for long term via the delrin or orings.

Hope this helps!

cjever19

Well-Known Member

Here is the sanke setup with spunding valve, pressure gauge, safety valve, and gas connector.

View attachment 175888

This is fantastic! Great design, you must have thought of everything! I'm inspired, thanks!

SilverZero

Well-Known Member

Hi friends, sorry to bring up an old-ish thread but I'm looking for a bit of guidance. Let's say I plan to use a 1/2" OD SS racking cane. What I'm hearing is that a 1/2" compression fitting won't seal it under pressure, so people are replacing the compression ferrule with o-rings.

Is that right? I'd like to keep the racking cane adjustable at least until I know what my final height will be to minimize trub while racking.

Is that right? I'd like to keep the racking cane adjustable at least until I know what my final height will be to minimize trub while racking.

Where did you hear that a nylon compression ferrule will not hold under pressure?

SilverZero

Well-Known Member

Where did you hear that a nylon compression ferrule will not hold under pressure?

I didn't say nylon, but I assumed SS compression fittings would use SS ferrules, and I was basing my question on this post.

I'm putting together a parts list now and I'm actually going to use a 3/8" OD racking cane, with a 1/2" NPT cross at the keg and a 1/2" NPT ball valve on the end of the cane. But my question is the same - will the included ferrules with a standard 1/2" MPT x 3/8" bore compression fitting hold pressure even if I undo and redo the height of the cane at least once or twice? I would have guessed there was no problem, but I wanted to make sure based on that post I linked above.

Get Bobby's ss 1/2 cane with his bore through compression fitting and call it a day. Seals just fine, I push with gas and it works like a charm. Side note, Bobby, if you wanted to make a nut that fits on that that had some wings on it so I wouldn't have to use a wrench when racking...I would buy one!

Islandboy85

Well-Known Member

You won't have any issue sealing if you use the regular parts from the compression fitting. You will however have a lot more trouble trying to slide the tubing through it. I'd reconnect the bored through compression fitting with o-rings as well.

If you buy the setup from me, or even just the bore through compression fittings, you have a choice of SS or Nylon Ferrule. The latter will seal just fine with light torque on the nut and will allow you to slide the cane to any depth over and over without hard setting SS ferrules. A pair of orings work the same way but you have to keep them well lubed to not destroy them when setting depths.

SilverZero

Well-Known Member

Got it, thanks for the advice!

Similar threads

- Replies

- 39

- Views

- 1K

- Replies

- 9

- Views

- 392