You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sam's Brew Box

- Thread starter sam

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

sam

Well-Known Member

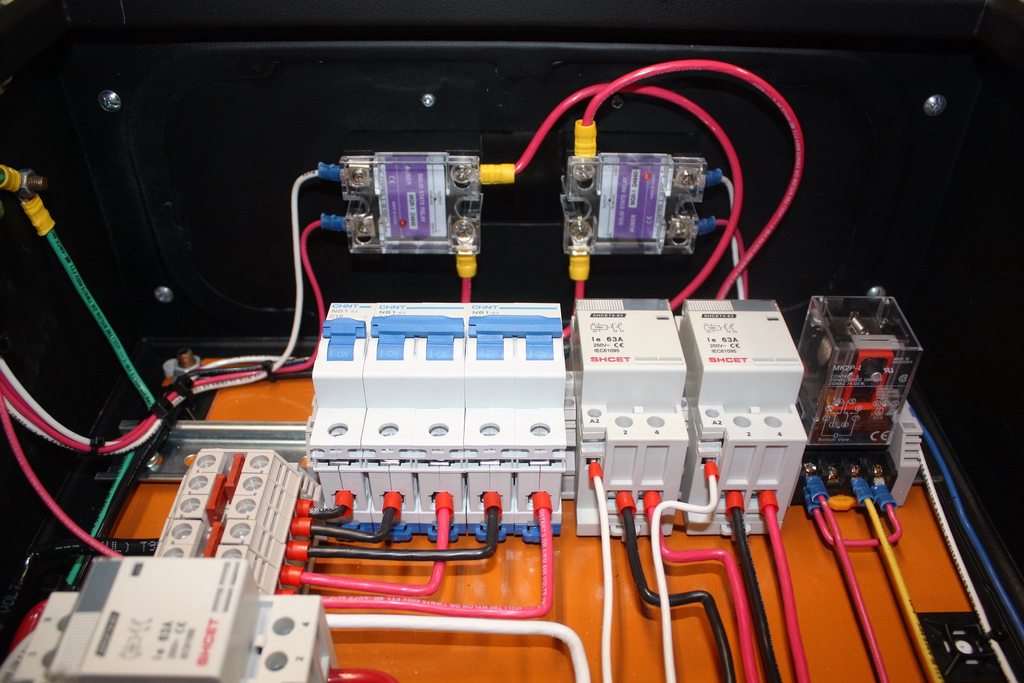

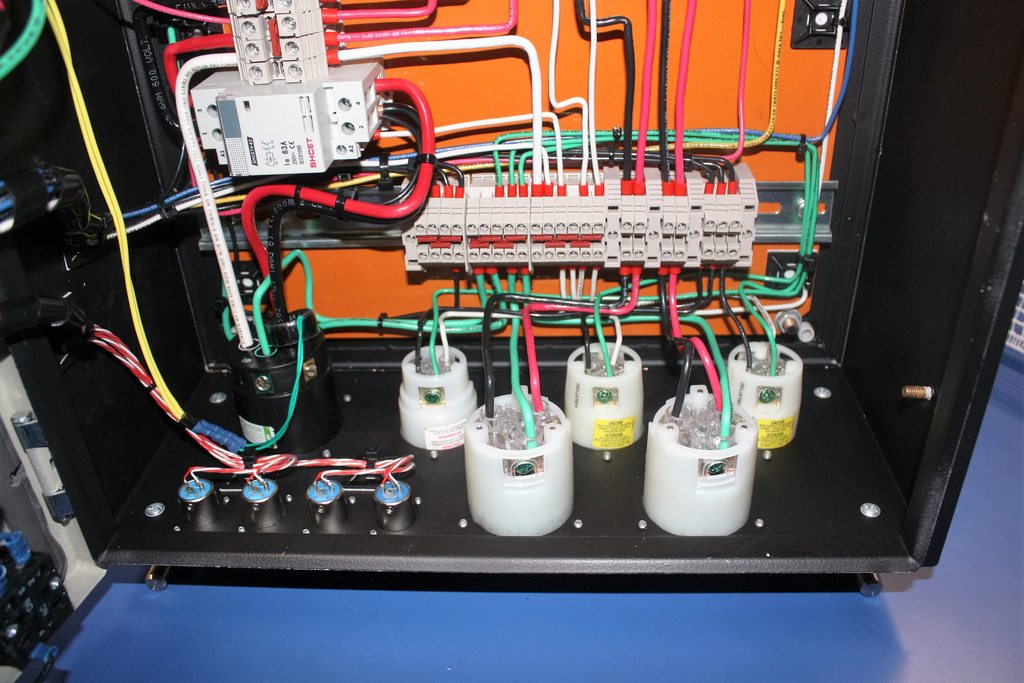

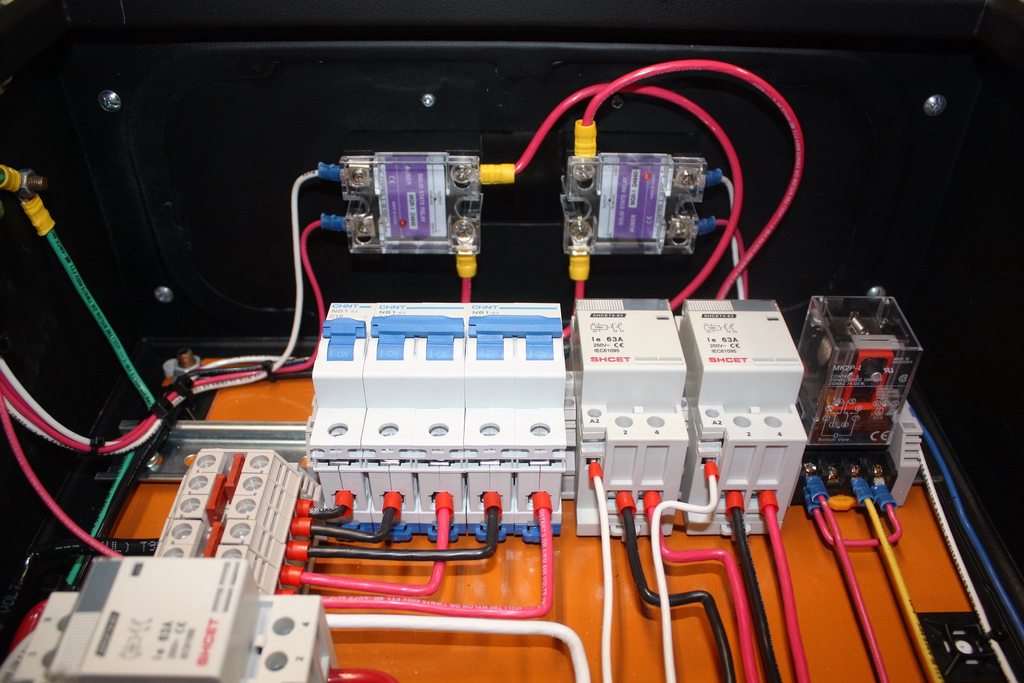

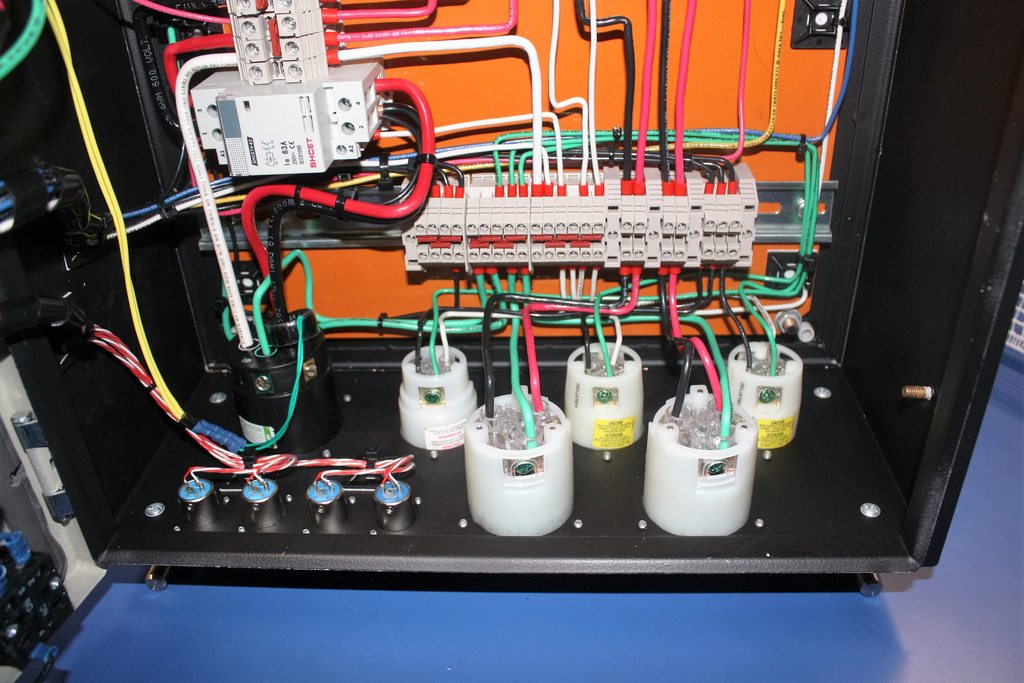

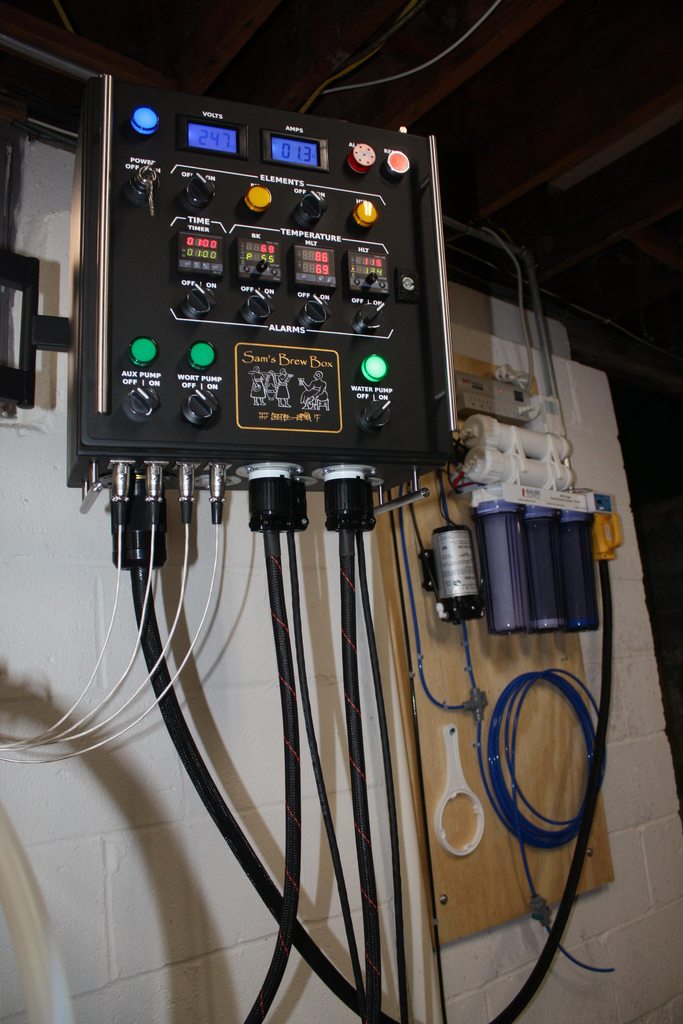

Progress...

That's some clean wiring!

You do know sharp 90 degree bends slows the electricity down, right?!? [emoji12]

You do know sharp 90 degree bends slows the electricity down, right?!? [emoji12]

sam

Well-Known Member

haha, thanks! I wonder how many g-forces those little electrons pull as they round the corners at that speed...

That's some clean wiring!

You do know sharp 90 degree bends slows the electricity down, right?!? [emoji12]

sam

Well-Known Member

I've been debating over where/how to mount the box. The wall probably would have been easiest but, when I was picking up the conduit for the outlet, I noticed the unistrut in the same aisle. Since my stand already resembles a big erector set...

sam

Well-Known Member

Oh, and by the way... pulling 6-gauge wire through 3/4 inch conduit is not easy.

sam

Well-Known Member

I'm getting close... did some tests with just water.

The 50 feet of herms coil definitely slows the flow down quite a bit. The mini ball valves I have are not full port and don't help but I really like them. I did some flow tests with and without them and didn't see much of a difference. With the mini ball valves I think it took about 10 more seconds to move 8 gallons of water from the boil kettle, through the herms coil and into the mash tun.

To help things, I upgraded the impeller on both pumps. Flow is much better through the coil now; still slow, but back to what I would consider normal (comparable to when I was direct firing the mash tun with propane during recirc).

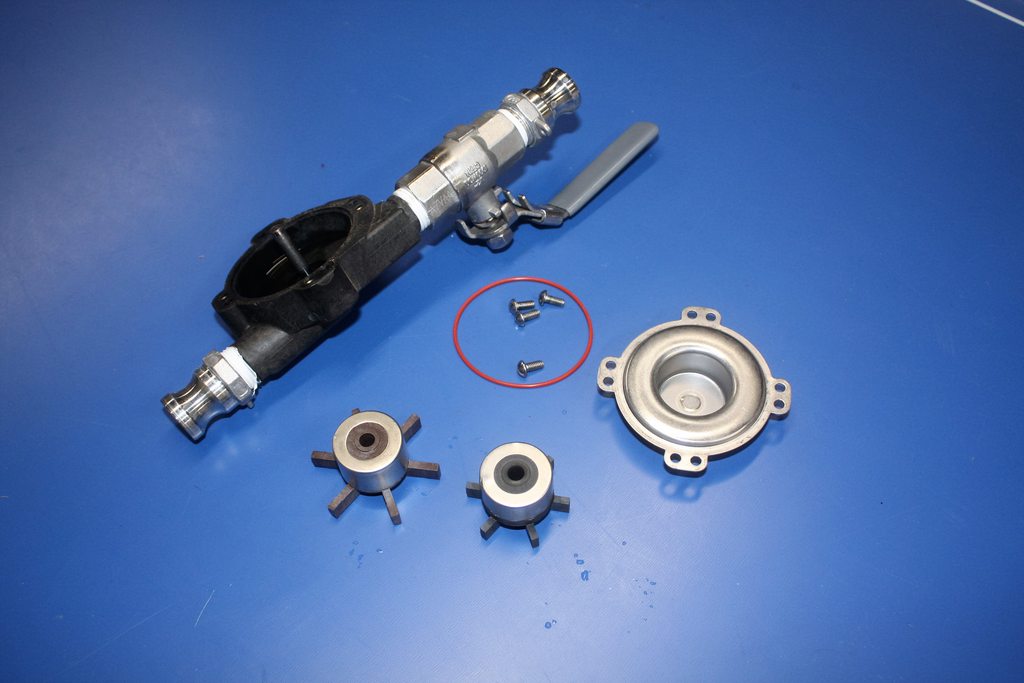

New impeller on the left... quite a difference in size. Note: apparently, this impeller upgrade is only worth it if your pump operates at 3000 RPM or higher (mine were both 3500 RPM). The 809 pumps that operate at 1750 rpm won't see any gains.

.

The 50 feet of herms coil definitely slows the flow down quite a bit. The mini ball valves I have are not full port and don't help but I really like them. I did some flow tests with and without them and didn't see much of a difference. With the mini ball valves I think it took about 10 more seconds to move 8 gallons of water from the boil kettle, through the herms coil and into the mash tun.

To help things, I upgraded the impeller on both pumps. Flow is much better through the coil now; still slow, but back to what I would consider normal (comparable to when I was direct firing the mash tun with propane during recirc).

New impeller on the left... quite a difference in size. Note: apparently, this impeller upgrade is only worth it if your pump operates at 3000 RPM or higher (mine were both 3500 RPM). The 809 pumps that operate at 1750 rpm won't see any gains.

.

sam

Well-Known Member

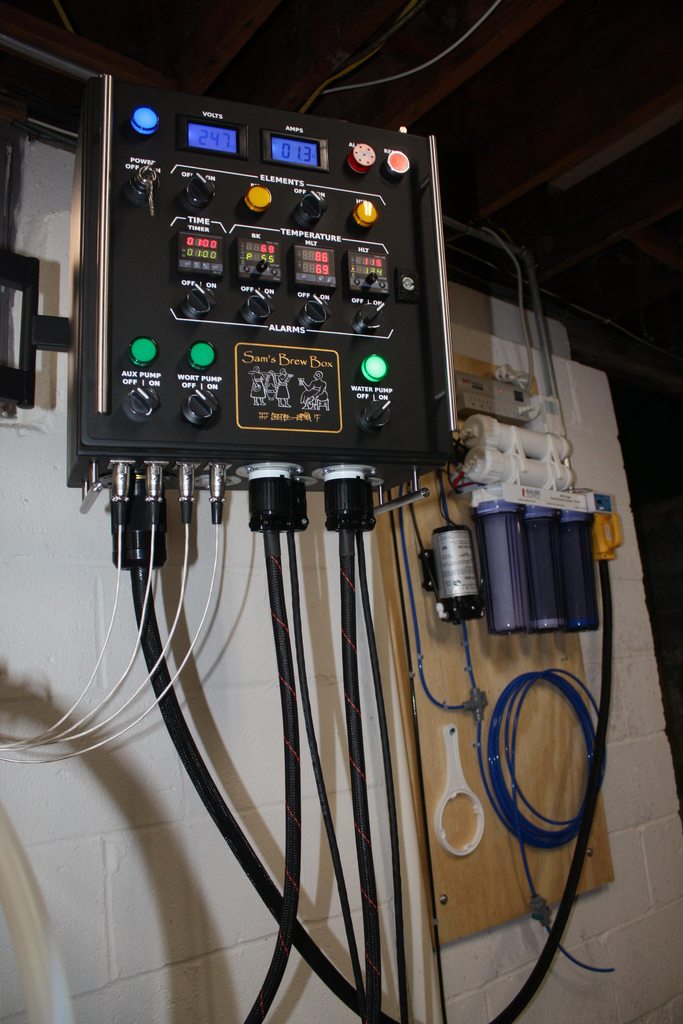

Finished!

I still need mark volumes on my sight glasses but, other than that, I think all I have left to do is brew.

Replaced all my tubing...

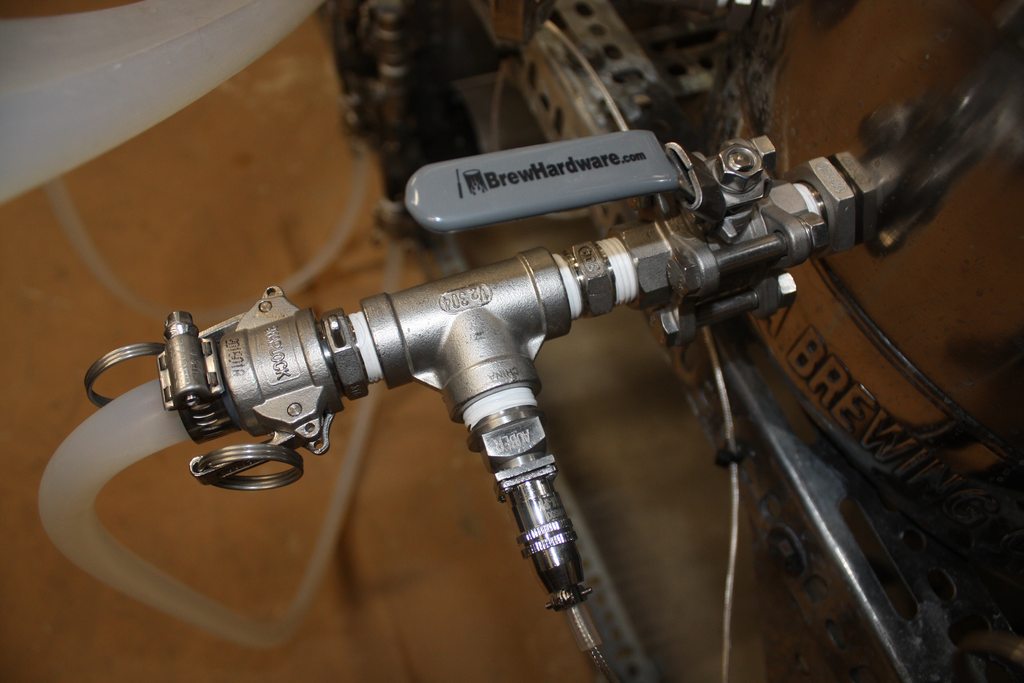

You'll notice on my panel that I don't use a PID for the MLT. Instead, I used an Auber SYL-2802 dual temp meter. The reason I did this is because, when researching my HERMS build, I found a lot of debate on where to measure mash temperature. Some measured at the top of the mash (HERMS output) and others at the bottom of the mash (MLT output). I decided to do both. In this picture, you can see where I put the temp probes. Between the probes and the analog thermometer, I think I have my bases covered.

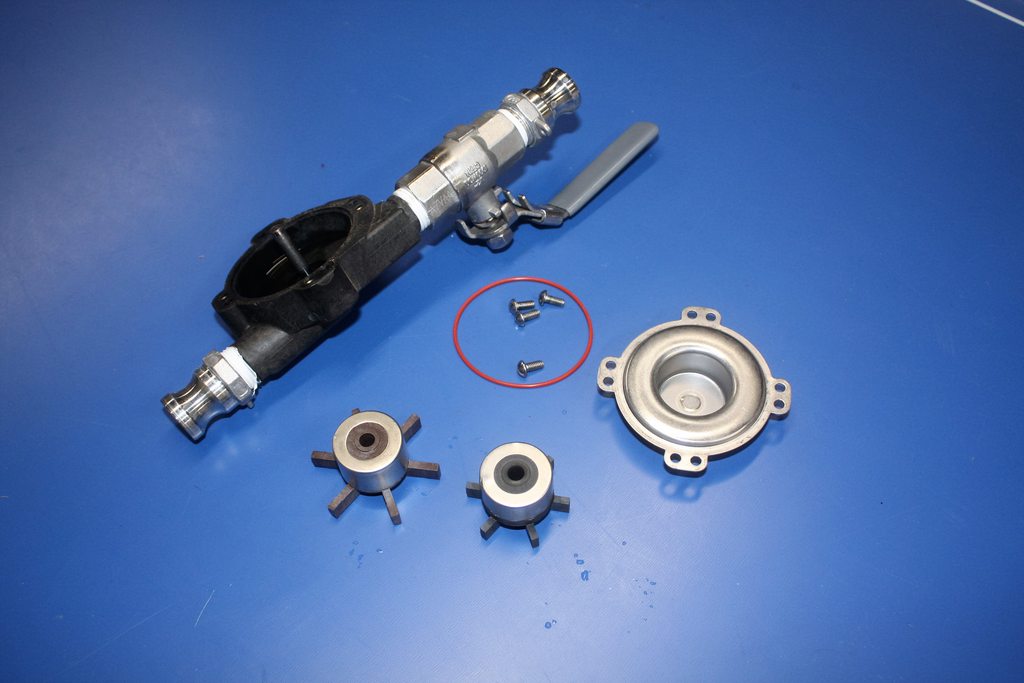

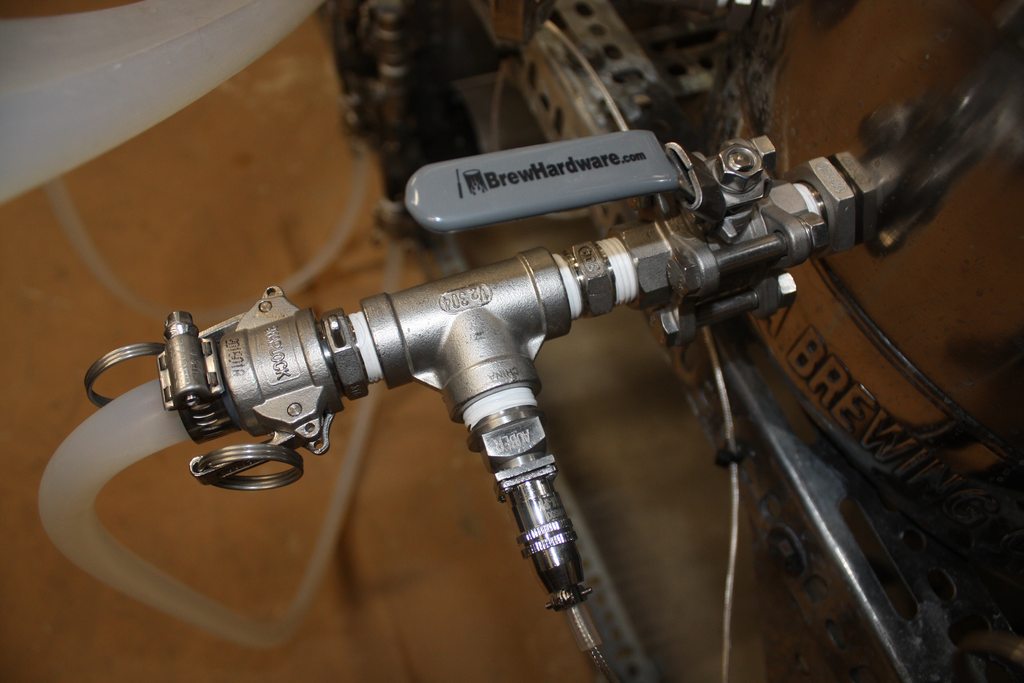

I got all of my weldless bulkheads, camloc fittings, element enclosures, etc. from @Bobby_M at brewhardware.com. He's got some great stuff and was a big help.

Another brewhardware.com upgrade for dosing oxygen...

Thanks for watching!

-Sam

.

I still need mark volumes on my sight glasses but, other than that, I think all I have left to do is brew.

Replaced all my tubing...

You'll notice on my panel that I don't use a PID for the MLT. Instead, I used an Auber SYL-2802 dual temp meter. The reason I did this is because, when researching my HERMS build, I found a lot of debate on where to measure mash temperature. Some measured at the top of the mash (HERMS output) and others at the bottom of the mash (MLT output). I decided to do both. In this picture, you can see where I put the temp probes. Between the probes and the analog thermometer, I think I have my bases covered.

I got all of my weldless bulkheads, camloc fittings, element enclosures, etc. from @Bobby_M at brewhardware.com. He's got some great stuff and was a big help.

Another brewhardware.com upgrade for dosing oxygen...

Thanks for watching!

-Sam

.

Beernip

Well-Known Member

Looking great!

sam

Well-Known Member

I had a problem with my SYL-2802... the temp readings were jumping around. After sending Auber a video they quickly diagnosed the issue as power line noise/interference and sent me a replacement unit with modified software. They added a notch filter to eliminate some of the noise from the 60Hz AC power and a low pass digital filter with parameters that can be changed in the settings menu.

Here's a before video of the temp readings "bouncing". I only powered the 2802 here to eliminate possible noise/interference from other components...

[ame="https://www.youtube.com/watch?v=JEfAvYYFgDI&feature=youtu.be"][YOUTUBE]JEfAvYYFgDI[/YOUTUBE][/ame]

Here, the temp readings are rock steady after installing the replacement that Auber reprogrammed...

[ame="https://www.youtube.com/watch?v=xDYxdROgI2I&feature=youtu.be"][YOUTUBE]xDYxdROgI2I[/YOUTUBE][/ame]

Just have to say that I'm really glad I purchased from Auber. You may pay a few dollars more compared to PIDs and other components you can find on Ebay, but it's so worth it just for the support you receive.

.

Here's a before video of the temp readings "bouncing". I only powered the 2802 here to eliminate possible noise/interference from other components...

[ame="https://www.youtube.com/watch?v=JEfAvYYFgDI&feature=youtu.be"][YOUTUBE]JEfAvYYFgDI[/YOUTUBE][/ame]

Here, the temp readings are rock steady after installing the replacement that Auber reprogrammed...

[ame="https://www.youtube.com/watch?v=xDYxdROgI2I&feature=youtu.be"][YOUTUBE]xDYxdROgI2I[/YOUTUBE][/ame]

Just have to say that I'm really glad I purchased from Auber. You may pay a few dollars more compared to PIDs and other components you can find on Ebay, but it's so worth it just for the support you receive.

.

Similar threads

- Replies

- 9

- Views

- 599