30Bones

Well-Known Member

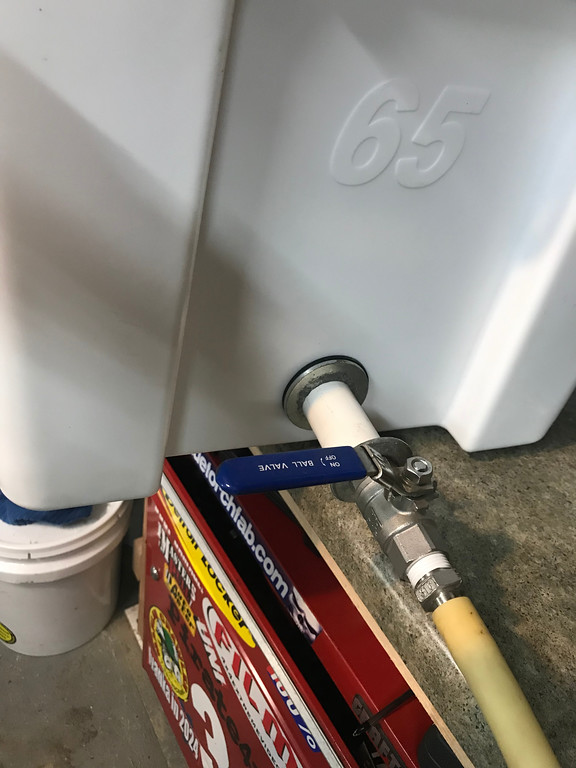

So after a couple years with my CO BIAB setup and having enough issues that made me almost quit the hobby I decided to dual purpose my 65 quart camping cooler to a MT. Years ago I used the Coleman Extreme for a MT with success and then I got the BIAB bug.

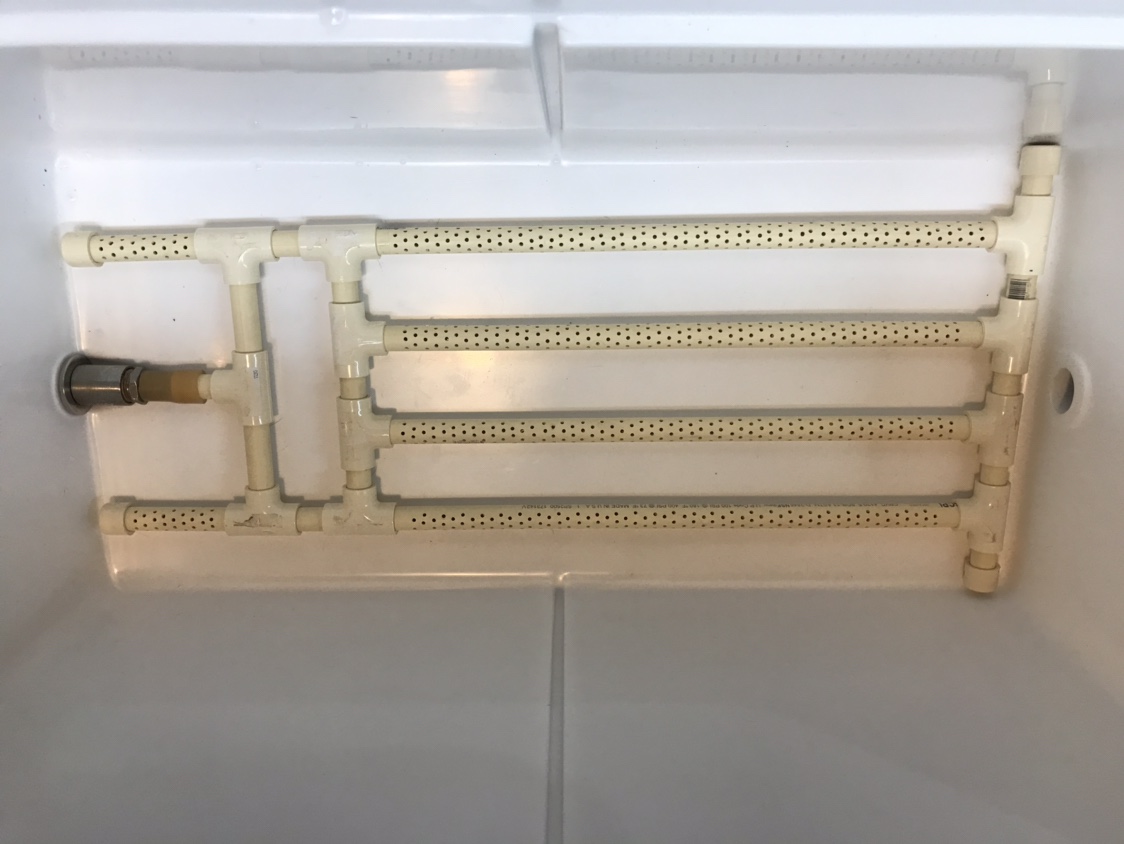

I am now in the process of building a CPVC manifold/false bottom but am also exploring having a custom stainless false bottom made as well. My 20 gallon electric kettle will now be my HLT and BK and my mash process is now back to being simple, quite, virtually trouble free and cleaning will actually be easier.

I am now in the process of building a CPVC manifold/false bottom but am also exploring having a custom stainless false bottom made as well. My 20 gallon electric kettle will now be my HLT and BK and my mash process is now back to being simple, quite, virtually trouble free and cleaning will actually be easier.