FreeParty

Member

I am wondering if anyone has experimented or is using a rocket stove to heat their brew?

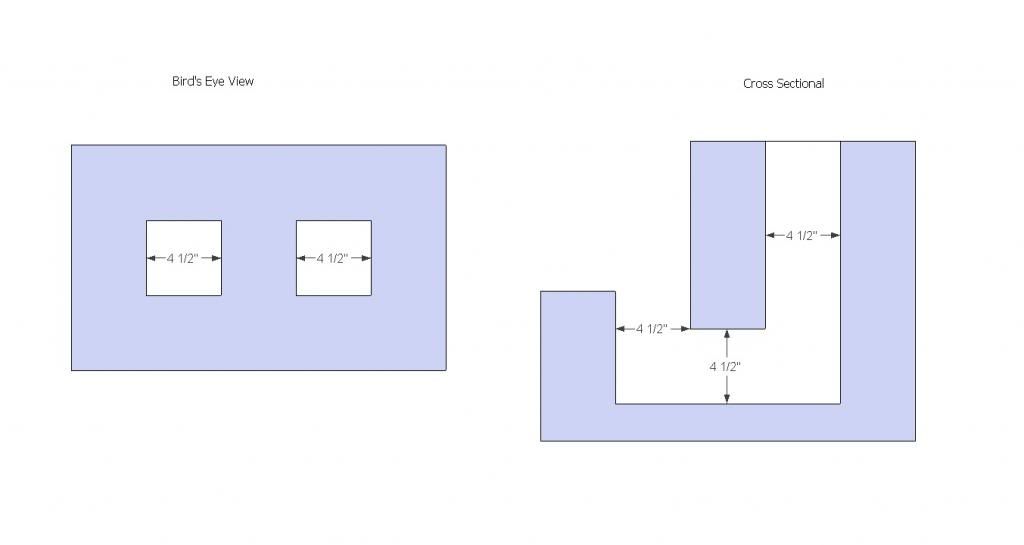

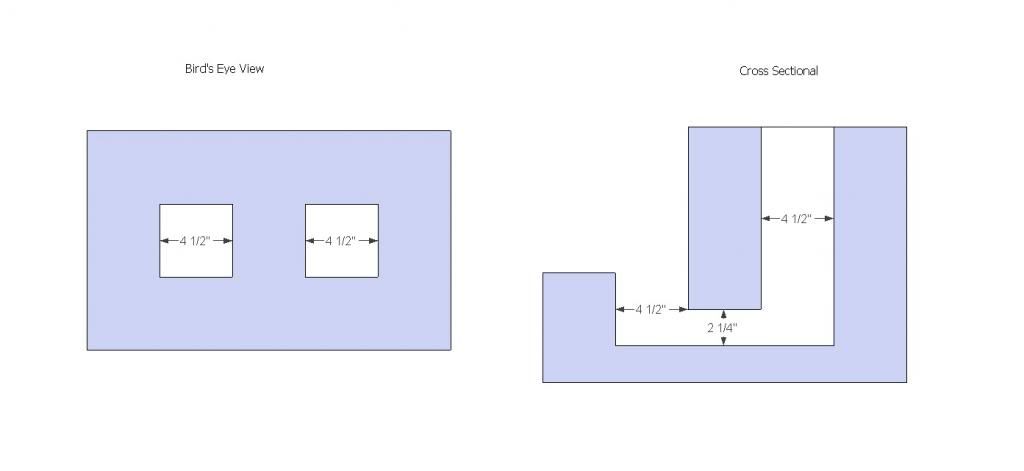

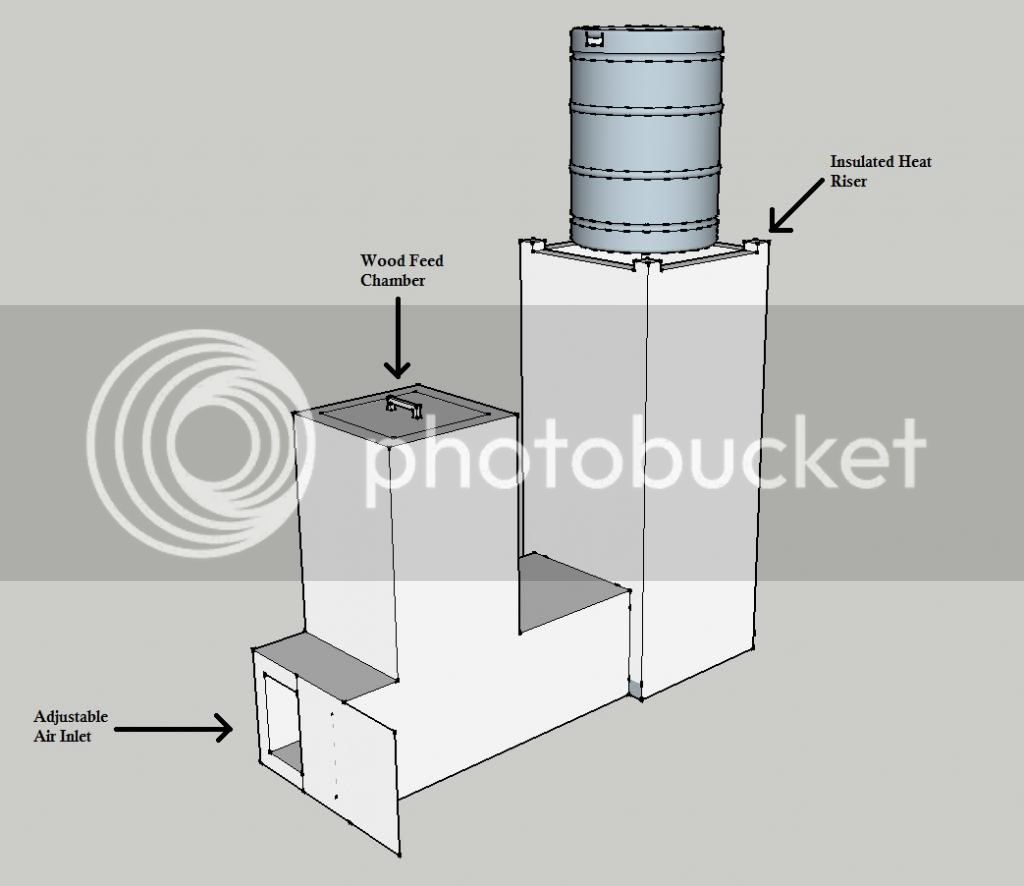

I am thinking of constructing a three tier keggle structure and heating my barrels with independent rocket stoves. I am still in the dreaming stages and looking for help on the dimensions of the stove.

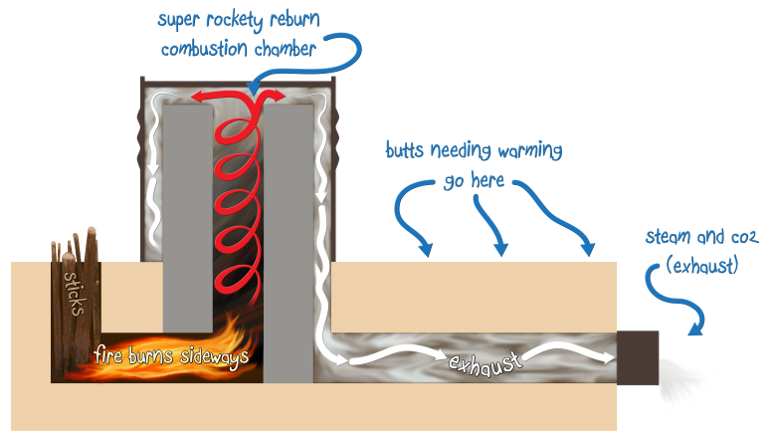

Those of you not familiar with a rocket stove, basically, it is a very efficient wood burning stove. In operation it does not create smoke because nearly complete combustion of the fuel is achieved. Its fuel is finger sized sticks.

Help me brainstorm with positivity on why this will work and possibly save home brewers money by not buying expensive stoves and fuel. I am aware of the hands on approach in this set up but that is why I home brew. If I wanted an automated machine to brew my beer I would buy manufactured beer.

I am thinking of constructing a three tier keggle structure and heating my barrels with independent rocket stoves. I am still in the dreaming stages and looking for help on the dimensions of the stove.

Those of you not familiar with a rocket stove, basically, it is a very efficient wood burning stove. In operation it does not create smoke because nearly complete combustion of the fuel is achieved. Its fuel is finger sized sticks.

Help me brainstorm with positivity on why this will work and possibly save home brewers money by not buying expensive stoves and fuel. I am aware of the hands on approach in this set up but that is why I home brew. If I wanted an automated machine to brew my beer I would buy manufactured beer.