deadwolfbones

Well-Known Member

Before you go there, I can't get warranty service. The Robobrew was an anonymous gift—don't know who sent it, no receipt. Came from MoreBeer, but... yeah.

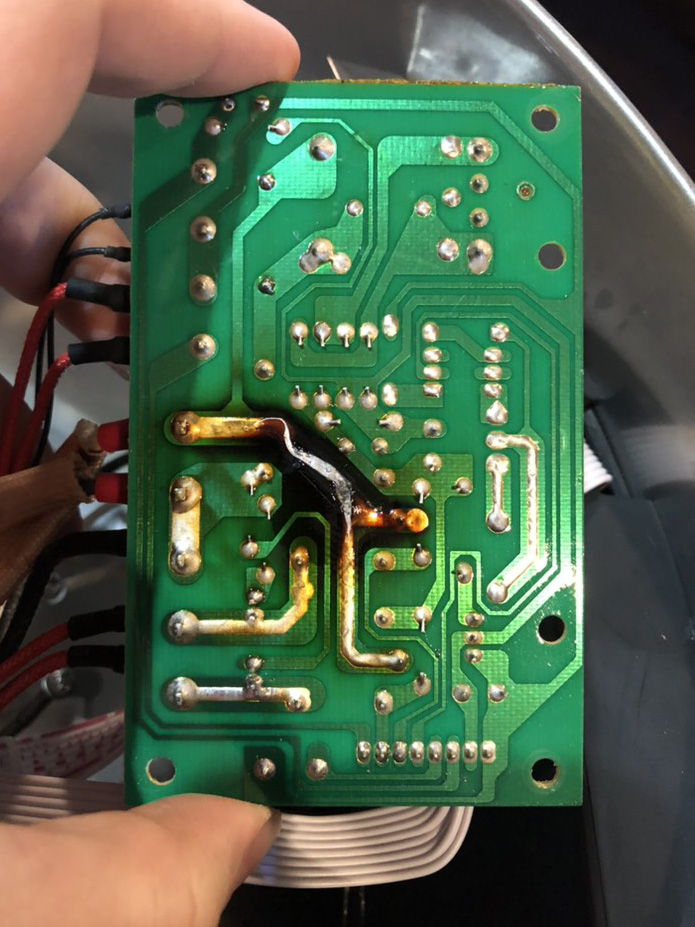

Yesterday I was midway through a 90-minute boil on a pilsner and the element just cut out. Light went off on the switch and the temp dropped to about 199F, which was the best the 500W element could do on its own. I finished the beer by transferring it to two stovetop pots. Blrgh.

Anyone had similar issues with their 1000W element? Any hope of an easy fix?

Yesterday I was midway through a 90-minute boil on a pilsner and the element just cut out. Light went off on the switch and the temp dropped to about 199F, which was the best the 500W element could do on its own. I finished the beer by transferring it to two stovetop pots. Blrgh.

Anyone had similar issues with their 1000W element? Any hope of an easy fix?