ok so I have a new to me Bobby_M rims tube and i haven't brewed using it yet. what I am trying to figure out is how to best use this new piece of equipment.

here's my gear: 3 keggles, 2 pumps, 1 rims tube, 1 NG burner:

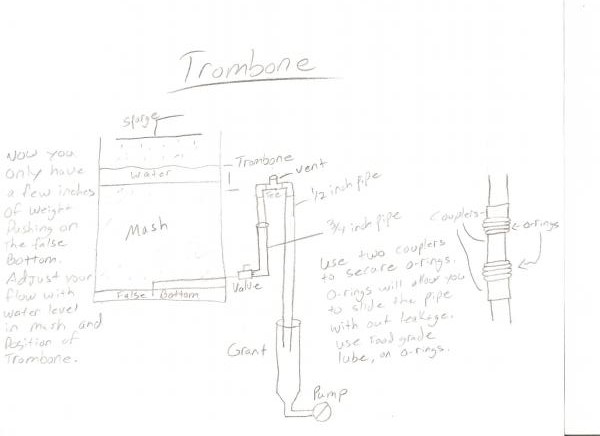

Mashing in: heat water in HLT to just a few degrees under what I want to mash at using the gas burner. put my desired water to grain ration into the MLT via one pump add grains and start the rims pump and rims tube up.

Mash out / Fly sparge: heat my water using my gas burner to XXX temperature not sure if it needs to be 180ish or close to mash out temps 168ish...

should I go from HLT to pump to Rims tube into the MLT into pump into my boil kettle

or

HLT to Pump to MLT to Rims tube to pump to boil kettle.

I know I want to fly sparge, I know I will be recirculating the entire mash, but its the mashing out / sparging im having trouble with.

what I did before was heat water to 180 and Fly sparge for about 45/60 minutes until I reached my pre-boil volume. if I noticed the water dropping i'd fire up the burner and get it back up. now I never took temperature to see what temp the water was going back into my MLT due to it being a igloo cooler and not wanting to get burned.

I eventually want to get a heating element into my HLT and another PID and temperature probe. end goal is an all electric system. but right now in my current rental house that is not an option. I do have a spa at this house I might be able to piggy back off of...

thanks for looking

-=Jason=-

here's my gear: 3 keggles, 2 pumps, 1 rims tube, 1 NG burner:

Mashing in: heat water in HLT to just a few degrees under what I want to mash at using the gas burner. put my desired water to grain ration into the MLT via one pump add grains and start the rims pump and rims tube up.

Mash out / Fly sparge: heat my water using my gas burner to XXX temperature not sure if it needs to be 180ish or close to mash out temps 168ish...

should I go from HLT to pump to Rims tube into the MLT into pump into my boil kettle

or

HLT to Pump to MLT to Rims tube to pump to boil kettle.

I know I want to fly sparge, I know I will be recirculating the entire mash, but its the mashing out / sparging im having trouble with.

what I did before was heat water to 180 and Fly sparge for about 45/60 minutes until I reached my pre-boil volume. if I noticed the water dropping i'd fire up the burner and get it back up. now I never took temperature to see what temp the water was going back into my MLT due to it being a igloo cooler and not wanting to get burned.

I eventually want to get a heating element into my HLT and another PID and temperature probe. end goal is an all electric system. but right now in my current rental house that is not an option. I do have a spa at this house I might be able to piggy back off of...

thanks for looking

-=Jason=-