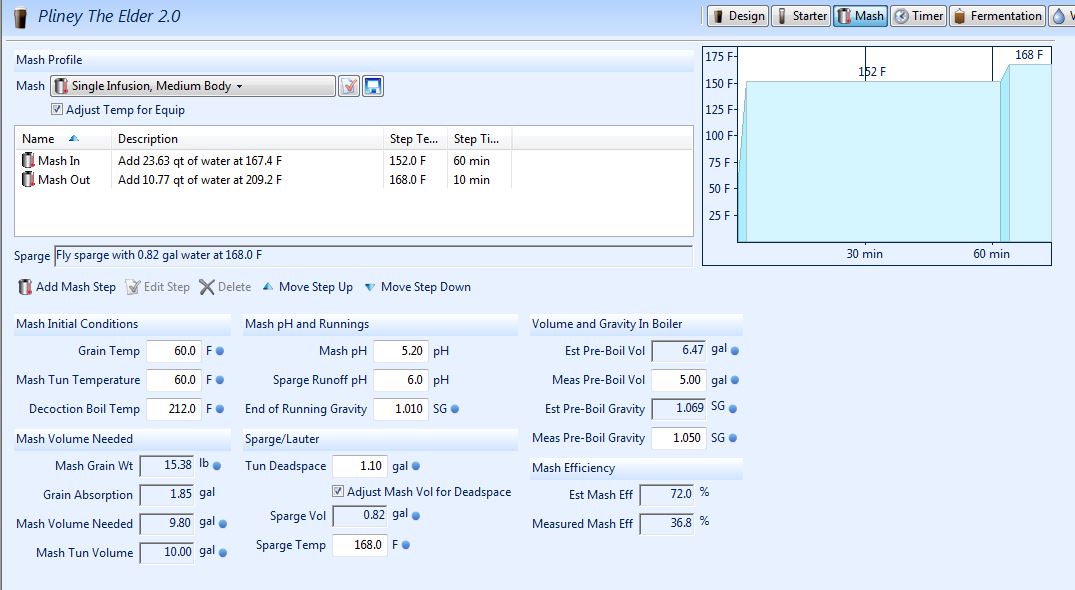

I'm brewing an Imperial IPA today. I'm in the process of building a brew system, but it's not done yet. However I want to utilize my pump and recirculate my mash to set my grain bed and clarify my sweet wort. I don't think I can recirculate for the entire 60 minutes as the temp will fall too much. I'm using a 10 gallon beverage cooler with a spinning sparge arm through the lid so I can keep the mash tun closed to help retain my mash heat. I've never recirculated before, and my purpose is to clarify my wort. So could I wait until 15 minutes remain then start to recirculate or should I wait until the 60 min has passed then start to recirculate kinda like a vorlauf. How long should I recirculate to clarify my wort? I could also pump some hot sparge water in to help mash out or hold temps while I continue to recirculate.

Any thought from someone experienced in recirculating would be greatly appreciated

Any thought from someone experienced in recirculating would be greatly appreciated