bobmcstuff

Well-Known Member

- Joined

- Feb 26, 2013

- Messages

- 589

- Reaction score

- 280

So, I decided I needed some sort of fermentation temperature control system. SWMBO told me in no uncertain terms that I'm not allowed another fridge just for brewing! So I had to come up with something else. Ambient temperature in my apartment is around 21-22c (70-72f), occasionally higher. Despite being in England where temperatures are not usually above 70f all that often, my apartment is on the 8th floor and gets heat rising up through the block.

My brief was:

1) As small as possible and able to store in a small space

2) Cheap as possible while retaining functionality

3) Able to hold ale fermentation temps (18c/64f) with the ambient temperature without needing constant attention

4) Able to increase temperature for D-rest or higher temp fermentation (e.g., saison)

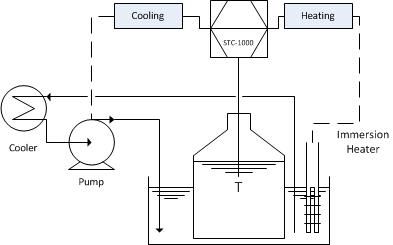

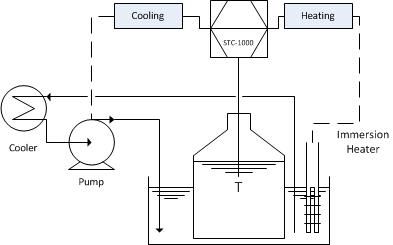

The design I came up with was the fermenter sitting in a bucket of water with this water cooled/heated as required, shown in the following diagram:

The cooler is an electric coolbox cooled by a peltier element and a fan. The coolbox claims to be able to hold temperatures 18c/32f below ambient as standard (obviously less with me circulating warm water through it).

The heater is a glass immersion heater from here which I picked up with an ingredient order (great site).

System as a whole:

Interior of coolbox:

The copper "element" was cheap to make, just a length of pipe, a hacksaw and a few compression elbows. I was initially concerned that it would not be effective enough, but actually in this application it works really well - I'm looking for gradual cooling here rather than the faster cooling you would want from a coiled copper wort chiller for example (with it's much larger contact area).

Pump shot:

The pump is designed for hi-spec computer cooling systems. I chose it because it is extremely quiet, has decent capacity (600l/hr) and claims 50,000hrs life. It's performing admirably at the moment.

So far, it has been holding 18c reliably. During high krausen (when the yeast is fermenting most vigorously) it takes a bit of babysitting, and I need to cycle PET bottles of ice through every ~8hrs to keep it cold. At other times, the Peltier is effective enough to keep it at the right temperature - I have noticed that the pump comes on every ~2-2.5hrs for 15-20 minutes. The controller is set to 18c with a +/-0.5c tolerance, so it tends to cool down to 17.9c then gradually heat back up to 18.5c when the pump kicks back in. I could set the tolerance to be tighter, but it seems to be working fine at the moment. I run the (sanitised) probe directly into the wort.

I'm away for work a lot so it would be better if it didn't need so much babysitting during vigorous fermentation, but since I usually do a 2 week primary, this just means I have to time the first week to be a week when I'm at home (it looks after itself in the second week). I imagine if there is a heatwave (or even an actual summer since we've had cr@p weather so far this year) it will also need quite a bit of ice.

There are a few improvements I have in mind:

1) Shorten hoses (reduce loss to environment)

2) Lagging on hoses (as before)

3) Better coolbox (while the peltier is decent, the coolbox itself is pretty cheap construction, it gets condensation on the outside which shows it's not too good at insulating)

4) Better/thicker insulation for water bucket (the stuff I have at the moment is thin radiator backing with foil on one side)

Any q's fire away. I'll put some pics of the temperature controller box up after I've had some lunch.

My brief was:

1) As small as possible and able to store in a small space

2) Cheap as possible while retaining functionality

3) Able to hold ale fermentation temps (18c/64f) with the ambient temperature without needing constant attention

4) Able to increase temperature for D-rest or higher temp fermentation (e.g., saison)

The design I came up with was the fermenter sitting in a bucket of water with this water cooled/heated as required, shown in the following diagram:

The cooler is an electric coolbox cooled by a peltier element and a fan. The coolbox claims to be able to hold temperatures 18c/32f below ambient as standard (obviously less with me circulating warm water through it).

The heater is a glass immersion heater from here which I picked up with an ingredient order (great site).

System as a whole:

Interior of coolbox:

The copper "element" was cheap to make, just a length of pipe, a hacksaw and a few compression elbows. I was initially concerned that it would not be effective enough, but actually in this application it works really well - I'm looking for gradual cooling here rather than the faster cooling you would want from a coiled copper wort chiller for example (with it's much larger contact area).

Pump shot:

The pump is designed for hi-spec computer cooling systems. I chose it because it is extremely quiet, has decent capacity (600l/hr) and claims 50,000hrs life. It's performing admirably at the moment.

So far, it has been holding 18c reliably. During high krausen (when the yeast is fermenting most vigorously) it takes a bit of babysitting, and I need to cycle PET bottles of ice through every ~8hrs to keep it cold. At other times, the Peltier is effective enough to keep it at the right temperature - I have noticed that the pump comes on every ~2-2.5hrs for 15-20 minutes. The controller is set to 18c with a +/-0.5c tolerance, so it tends to cool down to 17.9c then gradually heat back up to 18.5c when the pump kicks back in. I could set the tolerance to be tighter, but it seems to be working fine at the moment. I run the (sanitised) probe directly into the wort.

I'm away for work a lot so it would be better if it didn't need so much babysitting during vigorous fermentation, but since I usually do a 2 week primary, this just means I have to time the first week to be a week when I'm at home (it looks after itself in the second week). I imagine if there is a heatwave (or even an actual summer since we've had cr@p weather so far this year) it will also need quite a bit of ice.

There are a few improvements I have in mind:

1) Shorten hoses (reduce loss to environment)

2) Lagging on hoses (as before)

3) Better coolbox (while the peltier is decent, the coolbox itself is pretty cheap construction, it gets condensation on the outside which shows it's not too good at insulating)

4) Better/thicker insulation for water bucket (the stuff I have at the moment is thin radiator backing with foil on one side)

Any q's fire away. I'll put some pics of the temperature controller box up after I've had some lunch.