Brian Parfitt

Active Member

- Joined

- Apr 17, 2020

- Messages

- 42

- Reaction score

- 3

Hey folks. I'm concerned I have a contamination issue in my setup...

Last Feb I brewed an Imperial Bourbon Stout... When I kegged it, I noticed that it was tangy, almost sour tasting. Initially attributed this to the Bourbon being on the oak chips too long and over extracting tannins. figured I'd let it mellow over time and see how it did.. News flash. Still the same about a year later. Tangy/sour.

Back in early December I brewed another stout. This was the first batch brewed after the stout last Feb. Initial samples taken after a few days of fermentation showed promising flavor.. No off aromas etc. A touch sweet as it had not finished fermentation. I just took another sample as I setup my carb stone and it has a similar tangy/sour flavor to the stout brewed last winter.

I have never brewed a sour in my brewery and am using a spike conical. All loose pieces of the conical are cleaned with PBW and soaked in starsan prior to assembly. Assuming this is some type of contamination, am I able to clean the equipment I have? I'm pretty fastidious when it comes to cleaning and am concerned that I have an unfixable problem with my equipment.

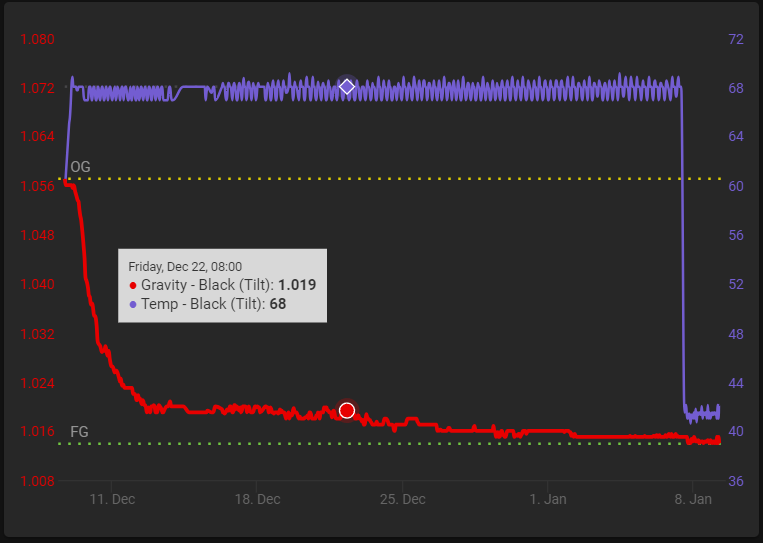

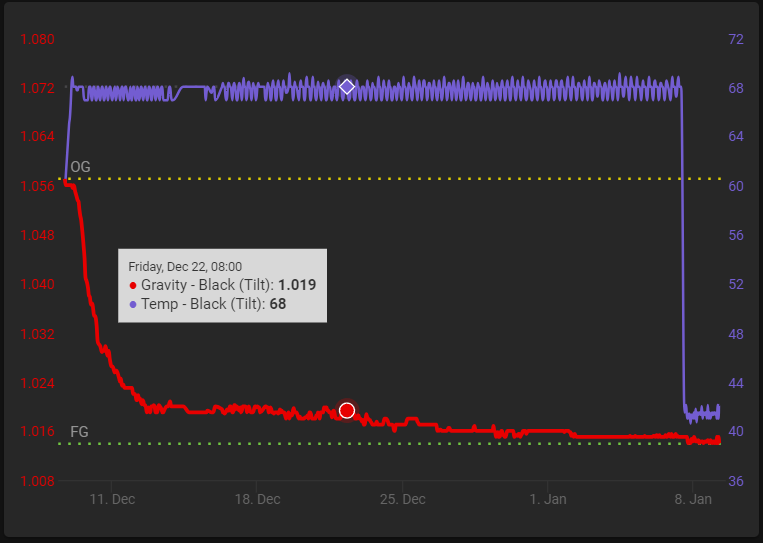

One interesting observation I had was the gravity data logged that clearly shows a primary, rapid fermentation taking place over the first 10 days(12/8 - 12/18).. The gravity stabilizes for a period of time at about 1.020. After some time, a secondary fermentation seems to start (around 12/18 or 12/19) that drops the gravity another few points from 1.020 to 1.015 over the course of 2.5 weeks. Could that have been signs of an bacteria/wild yeast going to work?

Appreciate any insight and hoping this isn't a lost cause.

Brian

Last Feb I brewed an Imperial Bourbon Stout... When I kegged it, I noticed that it was tangy, almost sour tasting. Initially attributed this to the Bourbon being on the oak chips too long and over extracting tannins. figured I'd let it mellow over time and see how it did.. News flash. Still the same about a year later. Tangy/sour.

Back in early December I brewed another stout. This was the first batch brewed after the stout last Feb. Initial samples taken after a few days of fermentation showed promising flavor.. No off aromas etc. A touch sweet as it had not finished fermentation. I just took another sample as I setup my carb stone and it has a similar tangy/sour flavor to the stout brewed last winter.

I have never brewed a sour in my brewery and am using a spike conical. All loose pieces of the conical are cleaned with PBW and soaked in starsan prior to assembly. Assuming this is some type of contamination, am I able to clean the equipment I have? I'm pretty fastidious when it comes to cleaning and am concerned that I have an unfixable problem with my equipment.

One interesting observation I had was the gravity data logged that clearly shows a primary, rapid fermentation taking place over the first 10 days(12/8 - 12/18).. The gravity stabilizes for a period of time at about 1.020. After some time, a secondary fermentation seems to start (around 12/18 or 12/19) that drops the gravity another few points from 1.020 to 1.015 over the course of 2.5 weeks. Could that have been signs of an bacteria/wild yeast going to work?

Appreciate any insight and hoping this isn't a lost cause.

Brian