Alteruser_404

New Member

- Joined

- Jun 16, 2020

- Messages

- 4

- Reaction score

- 0

Hey everyone,

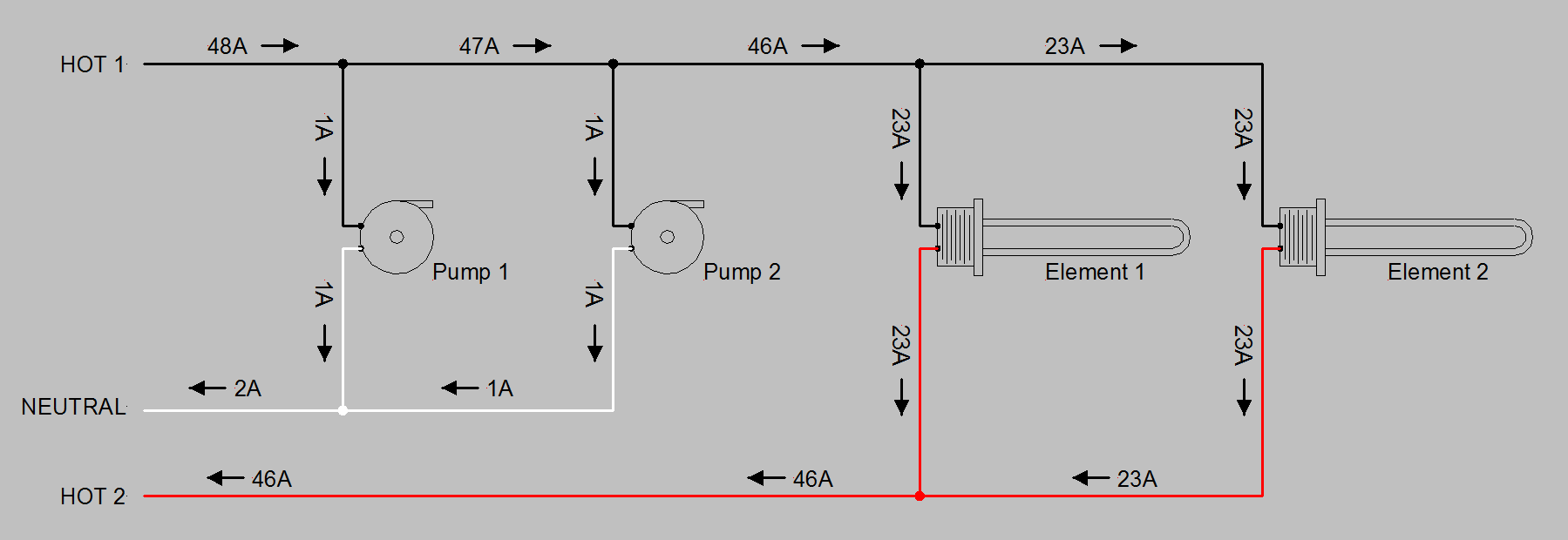

So I am trying to build a 220v portable GFCI controller with the ability to have one 120v for running a pump. I have it almost down on paper but I am confused about a couple of things, and I would also like a sanity check since I second guess myself quite a bit more than I'd like to admit. I have been reading through the forums and watching tons of videos however, I am still a little confused after looking over a few things.

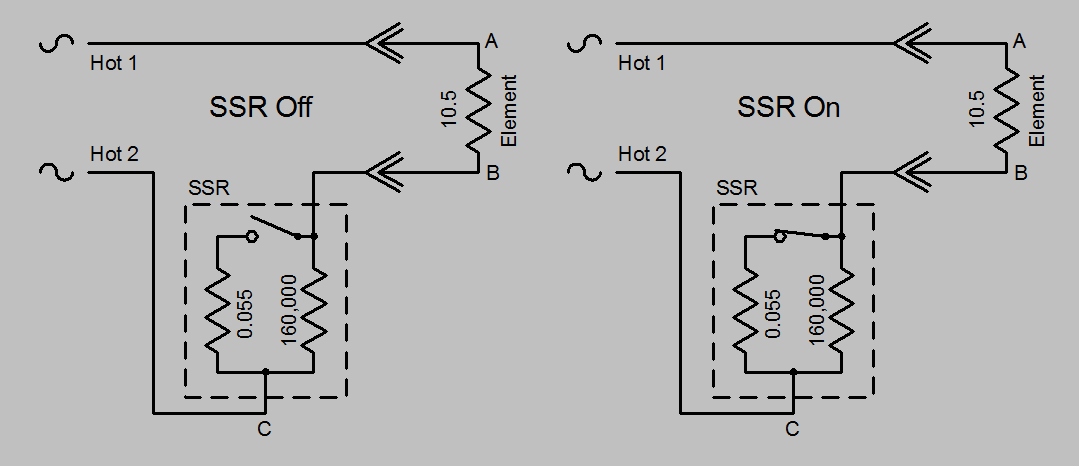

On a video I saw from Barley and Hops Brewing, they were wiring a 220v 3 prong cable to an Inkbird ITC-106VH. in the video he wired one leg of the incoming 220v to one side of the outlet, then the other leg to the SSR pin1 then from pin2 of the SSR to the other side of the receptacle. What is confusing me on this is once the system is turned on wouldn't there be a constant 120v leg sending power to the outlet, therefore running the heating element at 120v unit the SSR kicks in and runs the additional 120v leg to the other pin causing the element to receive a full 240v?

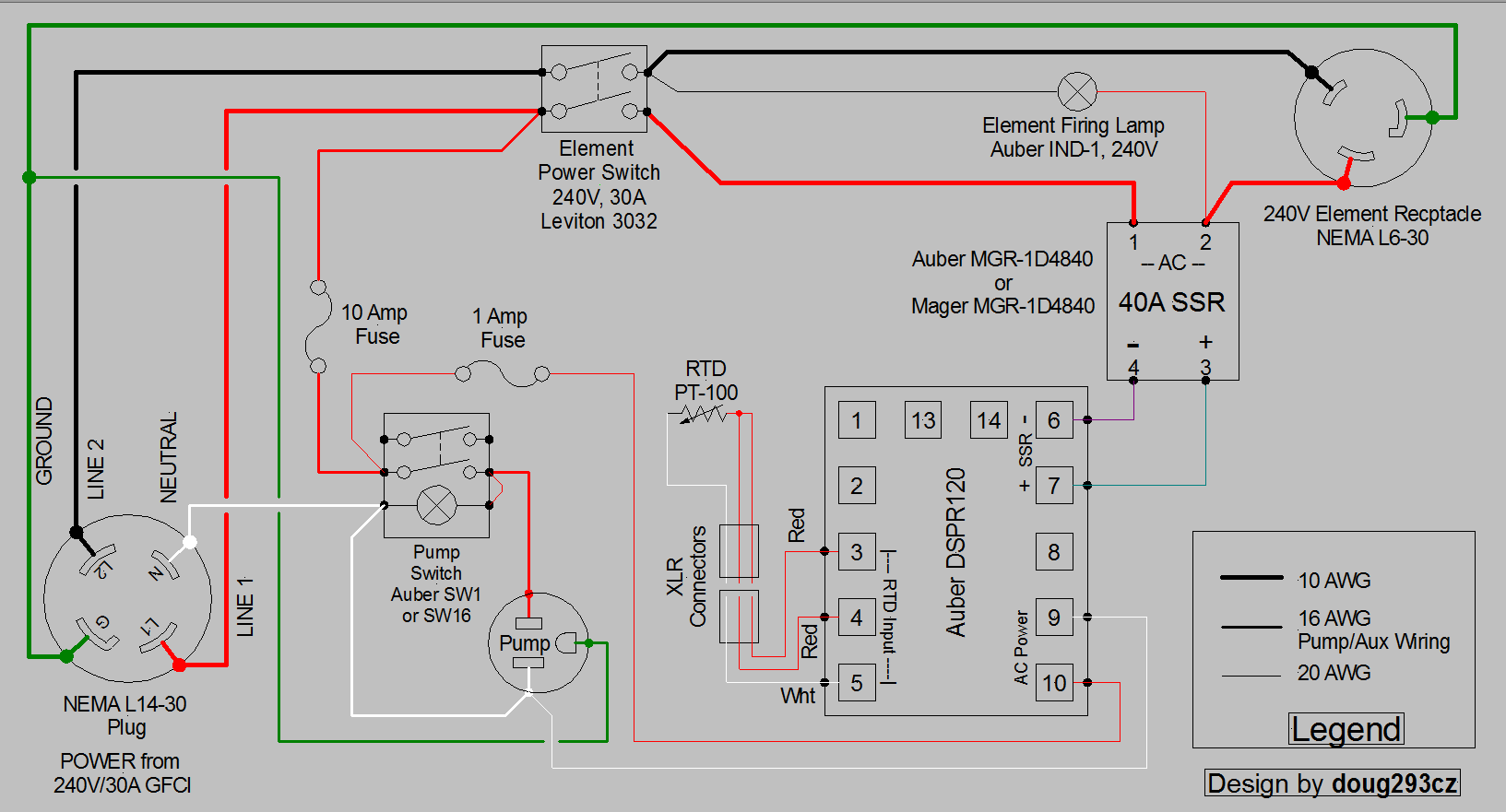

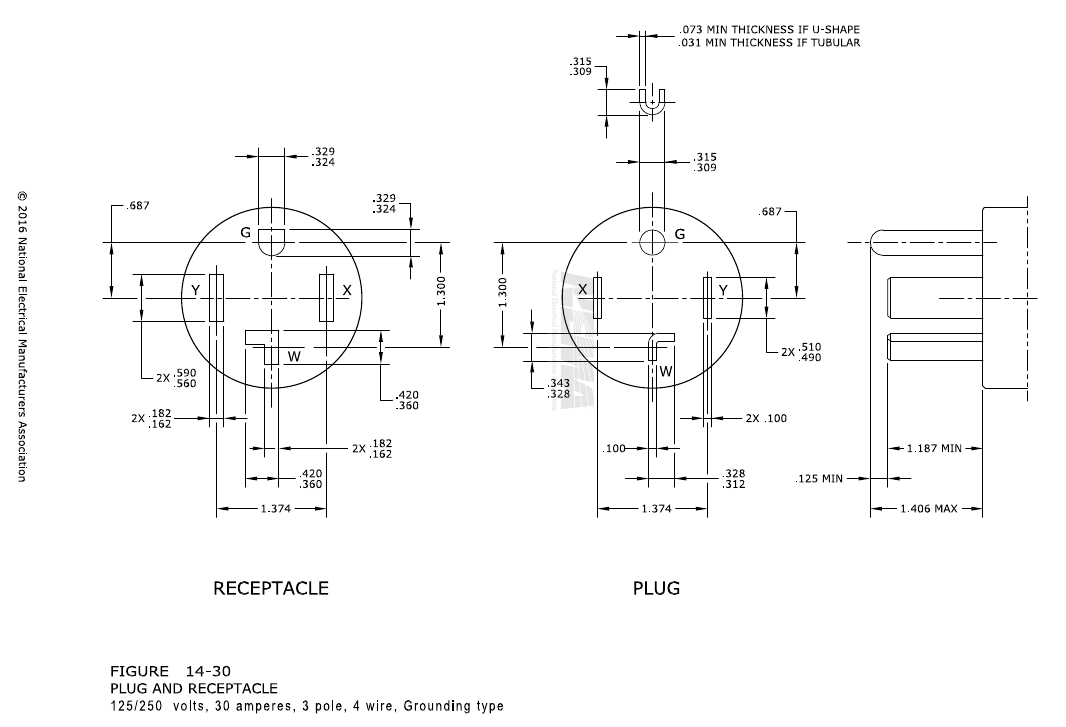

I have a 4 prong dryer outlet that I am going to be using to send power into the 50A GFCI SPA panel, then from the spa panel I am sending the power into the box I am building to house all of the electronics. There is a diagram of how the spa panel is wired, along with the incoming 220V from the 30A 220V dryer plug I am using. Where I am confused is when it comes to connecting the PID controller, SSR, and L6-30R wires. I do want to have one main switch that I will have to turn on even if the breaker is on. The 120v I can wire along pretty fine, the confusion is with the 220v. Do I send L1 from the top load out of the switch when on to the X of the L6-30R, then L2 to the SSR pin 1, then from SSR pin 2 to Y on L6-30R? I know I have to run power directly to the PID Controller so I will have to run a line from the two loads to the PID do I run L1 off the line going to X of the L6-30R to pin 10 on the Inkbird PID and then run L2 from Load on the main on/off switch to pin 9 on the Inkbird PID.

Pictured is also a digital AMP/Voltmeter I would like to have running so I know the load of everything that would be running in the system, 120v pump and fan included. That portion I am not sure of how exactly to wire up. I have posted a link to the unit below, any help would be greatly appreciated. Worst case scenario, I return it.

AC POWER METER.

Thank you for your time.

So I am trying to build a 220v portable GFCI controller with the ability to have one 120v for running a pump. I have it almost down on paper but I am confused about a couple of things, and I would also like a sanity check since I second guess myself quite a bit more than I'd like to admit. I have been reading through the forums and watching tons of videos however, I am still a little confused after looking over a few things.

On a video I saw from Barley and Hops Brewing, they were wiring a 220v 3 prong cable to an Inkbird ITC-106VH. in the video he wired one leg of the incoming 220v to one side of the outlet, then the other leg to the SSR pin1 then from pin2 of the SSR to the other side of the receptacle. What is confusing me on this is once the system is turned on wouldn't there be a constant 120v leg sending power to the outlet, therefore running the heating element at 120v unit the SSR kicks in and runs the additional 120v leg to the other pin causing the element to receive a full 240v?

I have a 4 prong dryer outlet that I am going to be using to send power into the 50A GFCI SPA panel, then from the spa panel I am sending the power into the box I am building to house all of the electronics. There is a diagram of how the spa panel is wired, along with the incoming 220V from the 30A 220V dryer plug I am using. Where I am confused is when it comes to connecting the PID controller, SSR, and L6-30R wires. I do want to have one main switch that I will have to turn on even if the breaker is on. The 120v I can wire along pretty fine, the confusion is with the 220v. Do I send L1 from the top load out of the switch when on to the X of the L6-30R, then L2 to the SSR pin 1, then from SSR pin 2 to Y on L6-30R? I know I have to run power directly to the PID Controller so I will have to run a line from the two loads to the PID do I run L1 off the line going to X of the L6-30R to pin 10 on the Inkbird PID and then run L2 from Load on the main on/off switch to pin 9 on the Inkbird PID.

Pictured is also a digital AMP/Voltmeter I would like to have running so I know the load of everything that would be running in the system, 120v pump and fan included. That portion I am not sure of how exactly to wire up. I have posted a link to the unit below, any help would be greatly appreciated. Worst case scenario, I return it.

AC POWER METER.

Thank you for your time.