Kernel_Lauter

Member

- Joined

- Jul 4, 2016

- Messages

- 20

- Reaction score

- 4

Kernel Lauter AKA ‘The Kernel’ is a 3 tier, gravity fed all grain brewing system with sophisticated PLC control all mounted on a stand with caster wheels which was fabricated by my dad. (Plug Forged Iron  )

)

I work for an automation company and I developed the taste for ale while on the road at exhibitions and that’s where my interest in making beer began. I started the usual way, using kits then I started to work my way up to all grain brewing. I then started thinking about how I could use what I’ve learnt from my job to help me with making beer.

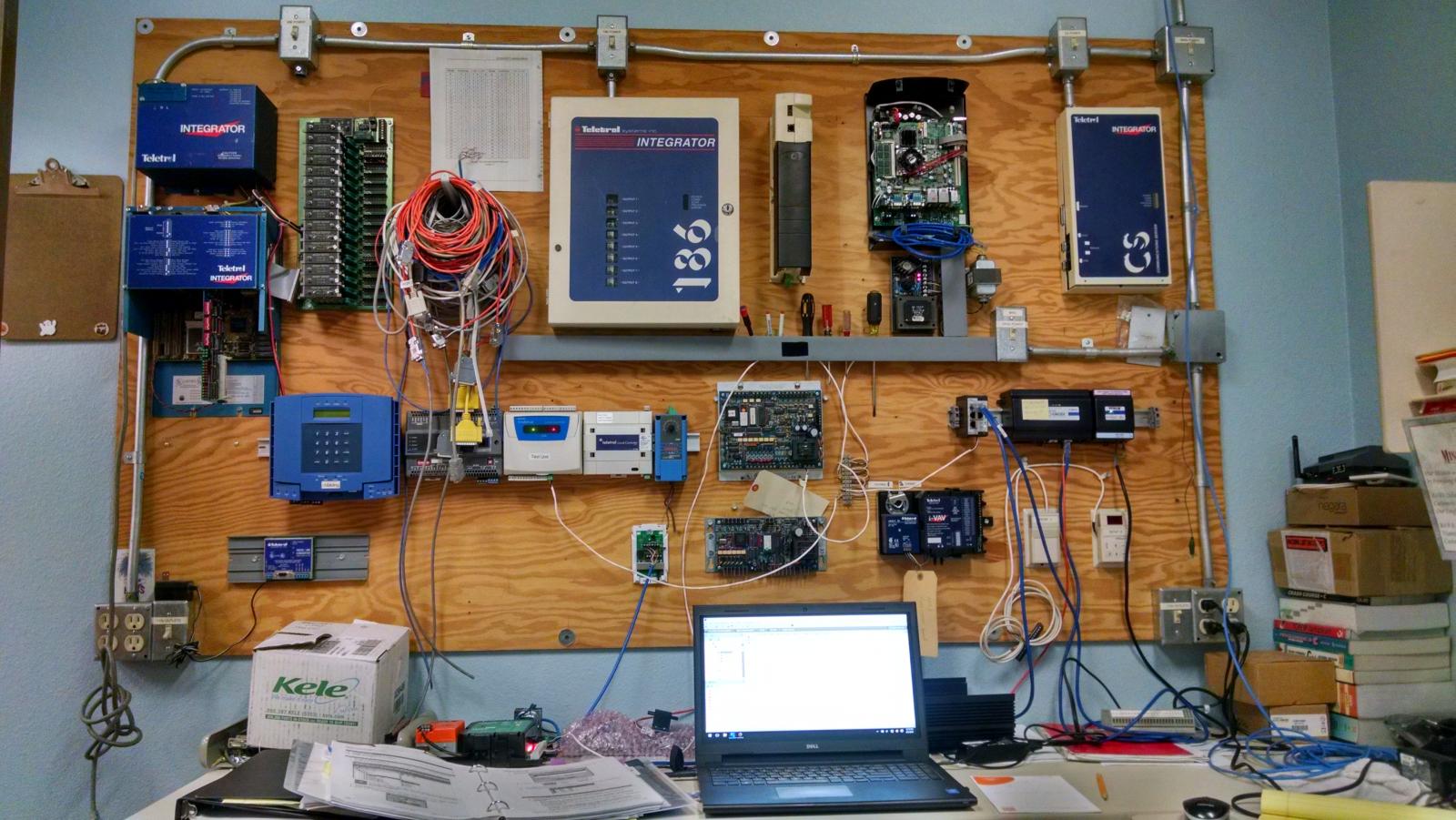

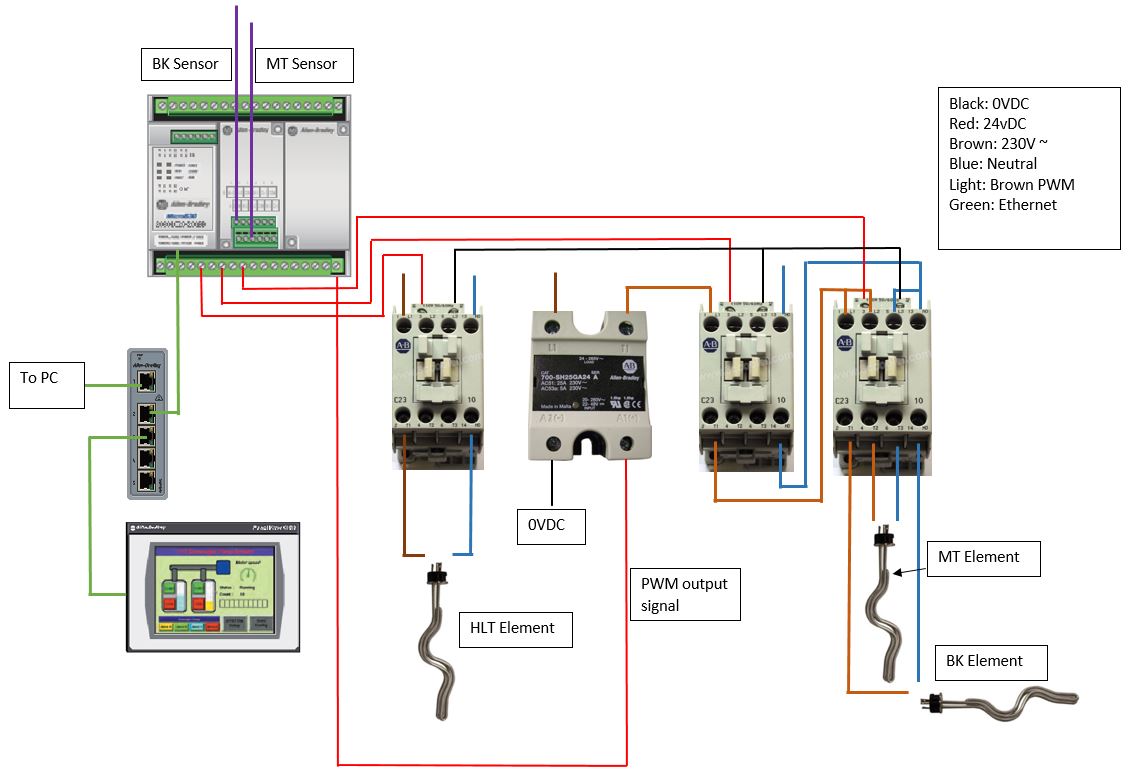

My college project consisted of a single vessel BIAB brewing system where I controlled the mashing temperatures with an Arduino. I then decided to upscale to this 3 tier system using Allen Bradley control equipment. I can control the entire system and see all the relevant information via a touch screen display which communicates with a Micro820 PLC over ethernet. The programming software for designing the graphics for the display and programming the PLC is free

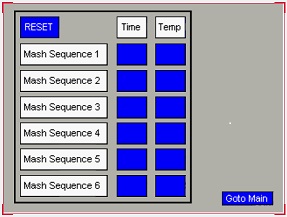

The display screens which I developed.

There are various different ways of controlling temperature with this Micro820 controller (simple Hysteresis and PID loop control) so I opted for hysteresis for the HLT as strike temperatures only really need to be close and with this method the temperature stabilises quicker. I then decided to use the PID function to control the mashing temperatures as this is where accuracy is most important. I didn’t think I’d stop there, I decided to have an automated mashing process which would not only allow me to have a complex mashing schedule but the PLC would manage it all for me if I dictated the temperature and time required.

There are some other neat features of the Micro820, it has a PWM output (pulse width modulation) which basically switches on and off very fast which allows the heating element in the MT and the BK to operate at various different temperatures rather than just on or off which I thought would be a great feature for preventing scorched wort/grains. The MT heating element sits under the false bottom with the temperature sensor and the wort is also recirculated constantly from the bottom of the MT to the top via a small pump. This helps with distributing the temperature for a more accurate reading and also uses the grain bed/false bottom as a filter so I get clear wort.

Micro820

I’m in the process of adding ultra-sonic level sensors so I’ll be able to tell how much fluid is in the HLT and BK. I’m hoping to write a program which will take a record of the before and after fluid levels (before and after mashing and after boiling) and let the PLC make a suggestion of how much water I’ll need for the next brew based on the losses from the previous. I was thinking about making this system fully automated using motorised or solenoid valves but I enjoy the interaction aspect.

I hope you find this interesting. it’s been great fun building this.

)

)

I work for an automation company and I developed the taste for ale while on the road at exhibitions and that’s where my interest in making beer began. I started the usual way, using kits then I started to work my way up to all grain brewing. I then started thinking about how I could use what I’ve learnt from my job to help me with making beer.

My college project consisted of a single vessel BIAB brewing system where I controlled the mashing temperatures with an Arduino. I then decided to upscale to this 3 tier system using Allen Bradley control equipment. I can control the entire system and see all the relevant information via a touch screen display which communicates with a Micro820 PLC over ethernet. The programming software for designing the graphics for the display and programming the PLC is free

The display screens which I developed.

There are various different ways of controlling temperature with this Micro820 controller (simple Hysteresis and PID loop control) so I opted for hysteresis for the HLT as strike temperatures only really need to be close and with this method the temperature stabilises quicker. I then decided to use the PID function to control the mashing temperatures as this is where accuracy is most important. I didn’t think I’d stop there, I decided to have an automated mashing process which would not only allow me to have a complex mashing schedule but the PLC would manage it all for me if I dictated the temperature and time required.

There are some other neat features of the Micro820, it has a PWM output (pulse width modulation) which basically switches on and off very fast which allows the heating element in the MT and the BK to operate at various different temperatures rather than just on or off which I thought would be a great feature for preventing scorched wort/grains. The MT heating element sits under the false bottom with the temperature sensor and the wort is also recirculated constantly from the bottom of the MT to the top via a small pump. This helps with distributing the temperature for a more accurate reading and also uses the grain bed/false bottom as a filter so I get clear wort.

Micro820

I’m in the process of adding ultra-sonic level sensors so I’ll be able to tell how much fluid is in the HLT and BK. I’m hoping to write a program which will take a record of the before and after fluid levels (before and after mashing and after boiling) and let the PLC make a suggestion of how much water I’ll need for the next brew based on the losses from the previous. I was thinking about making this system fully automated using motorised or solenoid valves but I enjoy the interaction aspect.

I hope you find this interesting. it’s been great fun building this.

but has anyone ever brewed a Westvleteren 12 clone?

but has anyone ever brewed a Westvleteren 12 clone?