Goblism

Well-Known Member

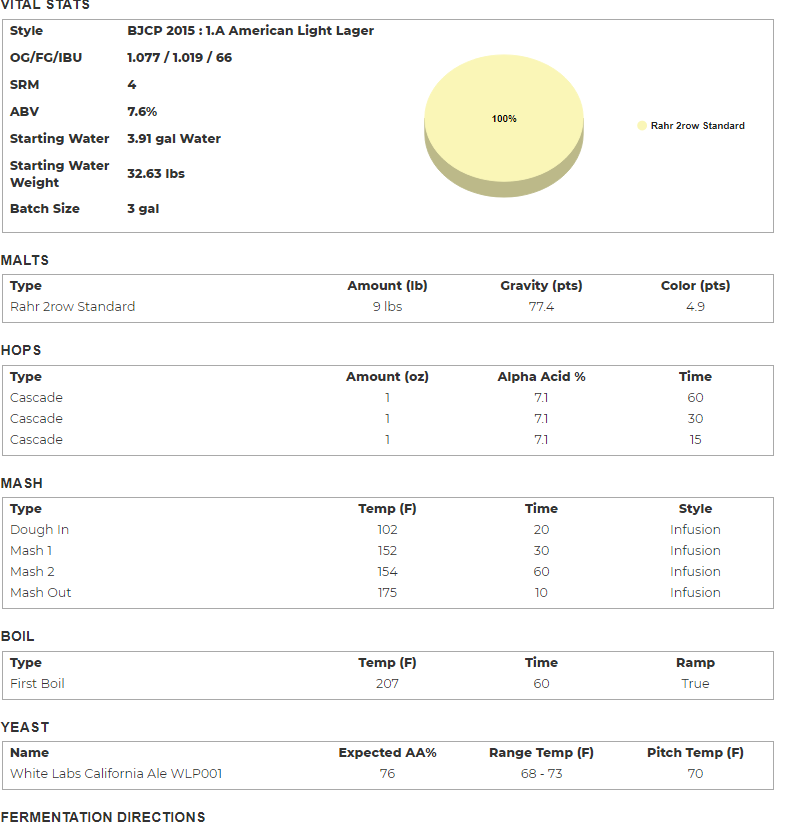

I haven't been able to progress on the beta recipe editor so I have used the regular.

Brewed my first batch today, can't believe how easy it was and liked being able to monitor the progress. Now a matter of running both units simultaneously in the z2 (z1+z1) configuration.

Still hoping the terminology changes from z1-z4 to simply the number of a unit's you have. It appears that registering the device follows the number of z units process.

Brewed my first batch today, can't believe how easy it was and liked being able to monitor the progress. Now a matter of running both units simultaneously in the z2 (z1+z1) configuration.

Still hoping the terminology changes from z1-z4 to simply the number of a unit's you have. It appears that registering the device follows the number of z units process.