@Kent88 :

Thanks for bearing with me while we got through the move! Finally have my brewery all unpacked and organized, heading to the LHBS today to check out the wares and stock up for my next brew!

This is gonna be a long post, so grab a beer...

Recipe -

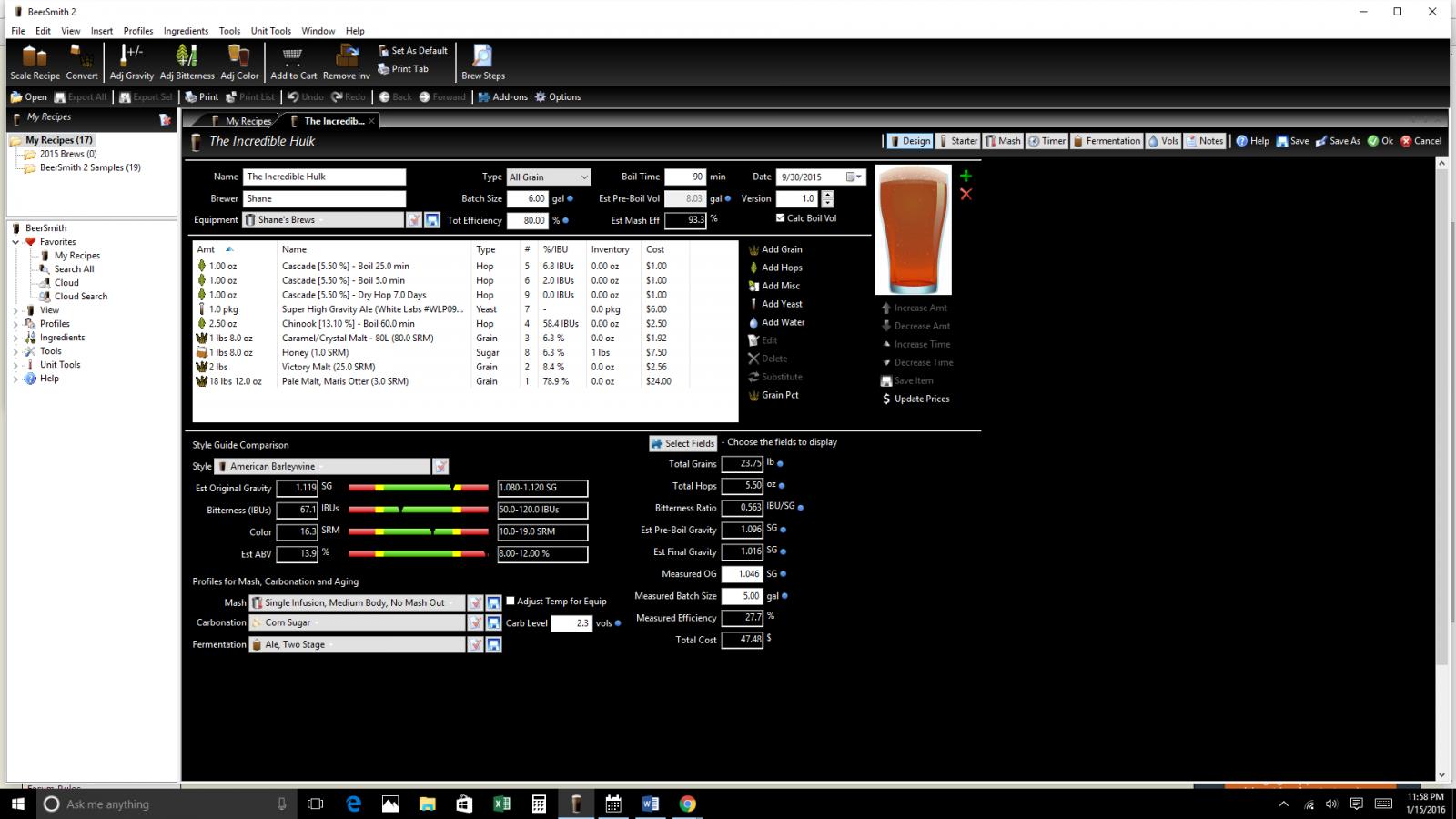

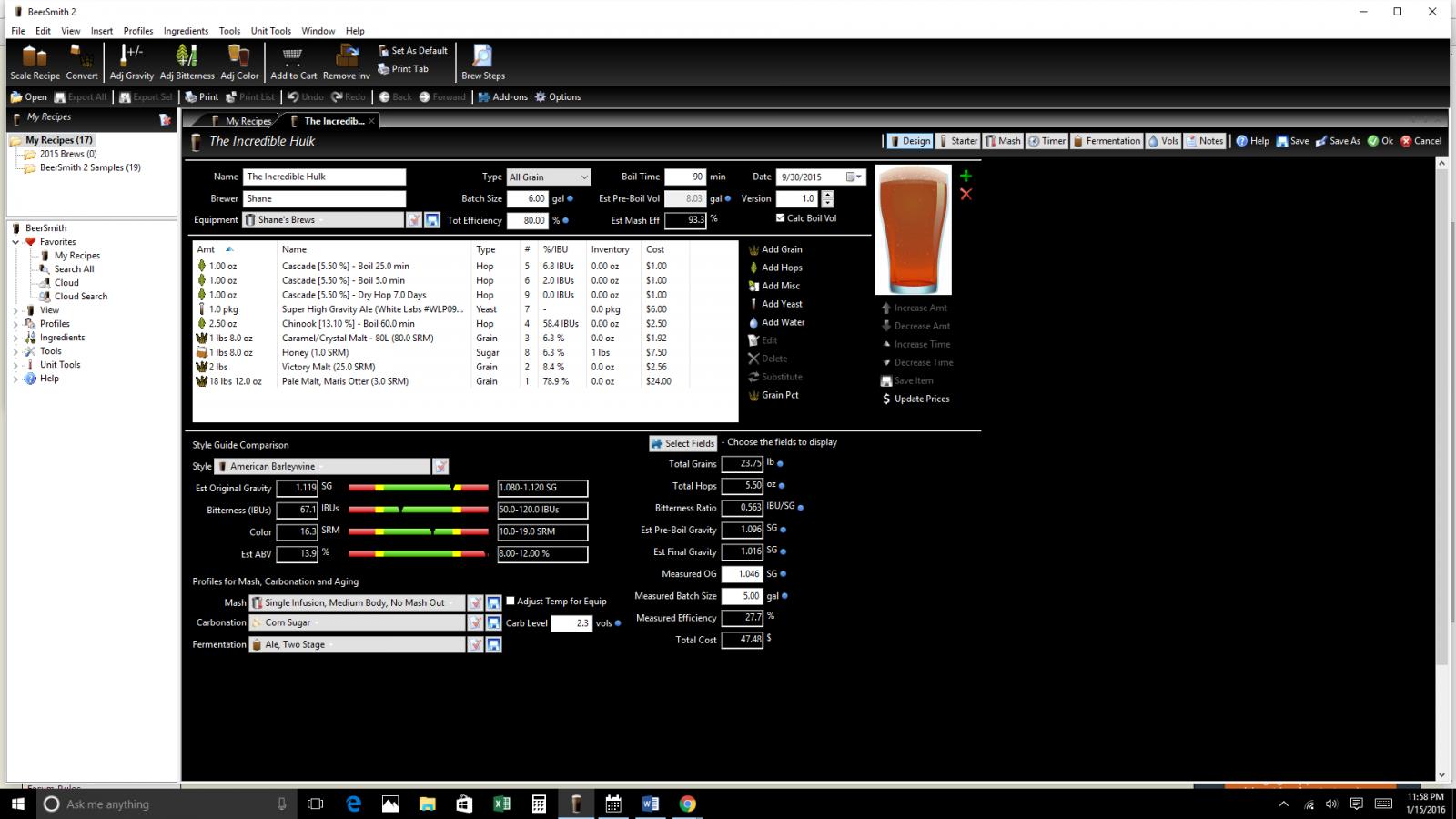

The Incredible Hulk - American Barleywine

5.5 gallon batch, all grain (sort of... had to improvise a bit)

75 minute boil (planned for 60, went over to try to increase the OG)

18 lb 12 oz Maris Otter

2 lb Victory malt

1 lb 8 oz Crystal 80

1 lb 8 oz Texas mesquite blossom honey (added at high krausen)

2.5 oz Chinook (13%) @60

1 oz Cascade (5.5%) @25

1 oz Cascade (5.5%) @5

WLP099 Super High Gravity Ale

95 minute mash (original plan for 60 minutes, but had some issues)

Planned mash temp was 150, actual was 148 at the start, and I lost a ton of heat, ended at 141

I had so many problems with this brew, but all of it is on me. I a 15 gallon mash tun that I've brewed with before, but hadn't used for a long time prior to this brew. I was way off on hitting my temps and my efficiency suffered a lot. I ended up with a pre-boil gravity of only 1.064 (7.25 gallons volume pre-boil), so I tossed in 3 lbs DME and bumped it to 1.085. OG ended up with ~4.5 gallons at 1.101 after the boil.

Second Runnings -

Bruce Banner - Party-gyle

Same grain bill as above (obviously), but I charged the mash with an additional 1.35-ish pounds of Maris I had laying around. I didn't note down how long I let the mash rest, but I'm guessing it was an hour since that's my typical mash length. Came in way low on the pre-boil gravity again (volume 8 gallons, gravity 1.025), so I tossed in another 1.75 lbs DME and bumped it up to 1.036. After a 60 minute boil I had right at five gallons with an OG of 1.048.

I changed up the hop schedule on this one just for grins, used HBC438 (15.7%) with half an ounce @60 minutes and half an ounce again @3 minutes.

My home made stir plate crapped out on my unexpectedly as I was getting ready for this brew, so my plan to make a massive 4.5-ish liter yeast starter went out the window. I went old school and made a one gallon starter wort and just shook it up as often as I could to mix some oxygen into suspension and build up the yeast count. I did that for about two days and split it between the two brews, again being astoundingly non-specific about how much went in to each, just that I decanted as much of the spent wort as I could and dumped most of the yeast in to the barleywine and the rest in to the small beer.

I oxygenated the barleywine for a full three minutes, the small beer for a minute (my usual). At that point I stuck the small beer in a corner and didn't mess with it again until bottling day.

I oxygenated the barleywine for a full minute again at 15 hours, and then again for one minute fifteen seconds when I added the honey at around 42 hours. By my math (which may or may not be very accurate) the honey would have pushed the OG up to 1.113. I did not pull a sample for gravity when I added the honey because I wasn't confident that I had mixed it thoroughly (all I could do was rock the carboy back and forth for a bit). I'm not sure if that makes a difference one way or another (does anyone out there know??). FG was 1.002, 16.1% according to the "alternate equation" ABV calculator for high gravity beers on the Brewer's Friend app.

As for oxidation, I can't say simply because I haven't tasted the barleywine as of yet. I bottled it on the 5th of May, and at that time I didn't taste any off flavors, but I can't say how much it will have changed once it carbs up and conditions. My thought, based on observation of the fermentation and on something Michael Dawson said in an episode of Brewing TV, is the 099 was still chugging along strong and possibly still multiplying (I've never seen such a massive yeast cake) that it sucked up any oxygen I put in there and put it to good use repairing cell walls so they could handle the high alcohol environment.

The small beer is very tasty. Sort of hop forward, but not bracing like an IPA or even a bitter, but it had this kind of crisp finish to it like a strong black tea. I'm not sure I would use the HBC438 in any of my other recipes, but it worked out really well for this batch since I was just looking to have a little fun and swag out a beer to keep me busy drinking while I wait for the barleywine to get some age on it. FG for this one was 1.002 as well, 6.04%.

As for what I'd do differently, I could kick myself for not messing around with those larger mash and hot liquor tuns before brew day. It would have benefited me to be more familiar with them in terms of lost volume and temperature swings. I also would have done a little more research in to adjusting my grain bill for potential lost efficiency with a big beer like this.

Advice for people contemplating a parti-gyle - do it. Honestly, it was fun as hell. I had some challenges, but I ended up learning a lot from them in the long run, and I ended up with two beers for the price of one. I will definitely do this again some time. I will say, though, it was good that I had a buddy with me on brew day. There was a lot of heavy lifting involved, and it was nice to have someone that could help.

Hope this answers your questions for now. Let me know if you have any others, and I'll keep you posted on how the barleywine tastes. I was planning on keeping them in the closet until at least Thanksgiving, but frankly the curiosity is killing me and patience is not my forte.

Stay tuned!