ihavenonickname

Well-Known Member

I'd like to try out overnight mashing with multiple steps. And I'm having a hard to wrapping my head around how this will affect the body and finishing gravity of my beer.

My plan is to mash in and follow this program:

146F for 120 minutes

156F for 120 minutes

161F for 30 minutes

172F for 4 hours... or less.

This will allow me to wake up, lift the basket, sparge and boil

My questions:

Would this lead to an highly attenuative wort?

Would it lead to a full bodied wort?

If I wanted it to lean more dry/alttenuative (for a WCIPA) what adjustments should I make?

If I wanted to make it fuller bodied (for a NEIPA) what adjustments should I make?

Does a step in the 158-160 build dextrins and body the longer it goes?

Any other recommendations for mashing over night but still having some control over body?

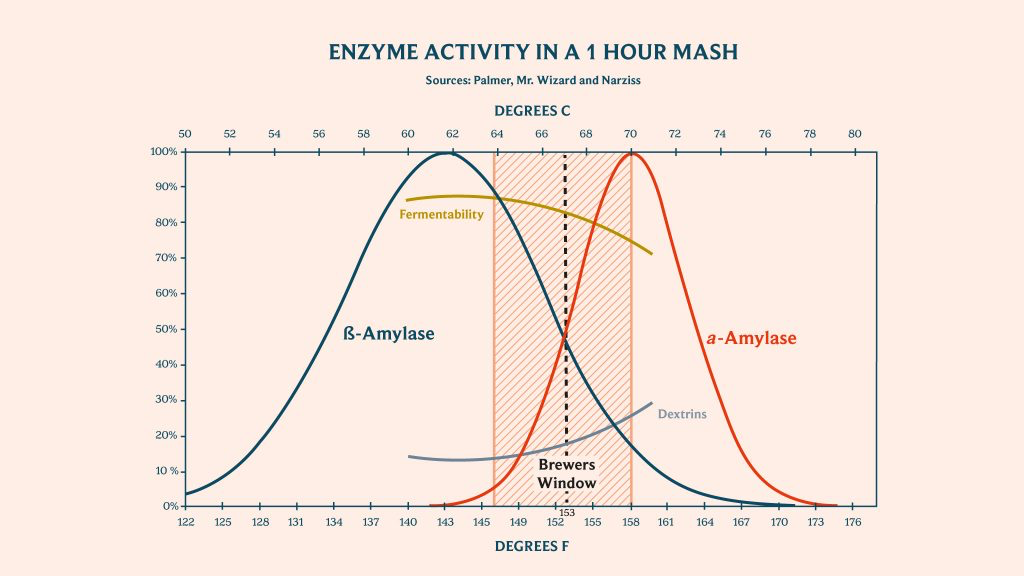

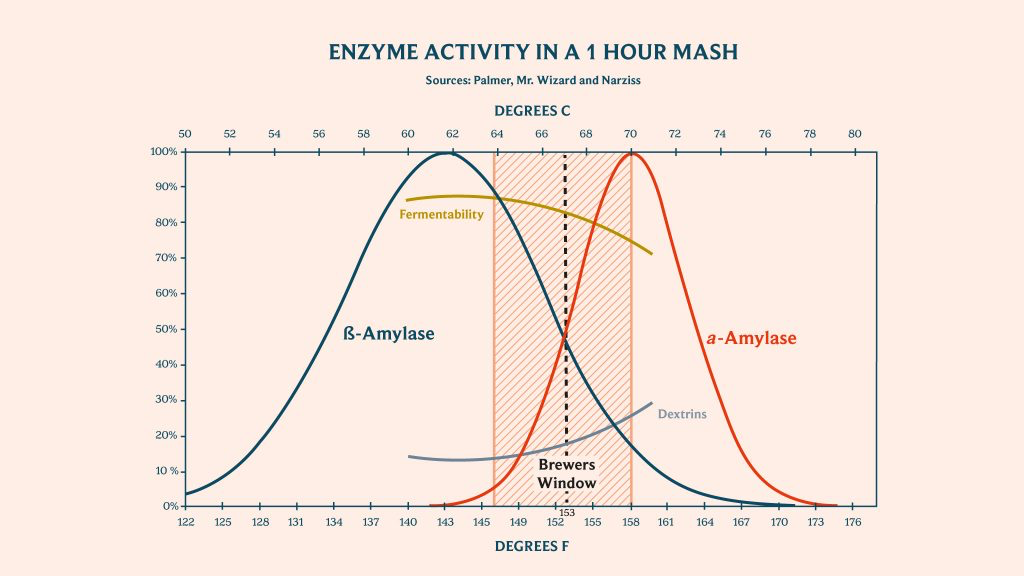

This chart is a helpful point of reference

My plan is to mash in and follow this program:

146F for 120 minutes

156F for 120 minutes

161F for 30 minutes

172F for 4 hours... or less.

This will allow me to wake up, lift the basket, sparge and boil

My questions:

Would this lead to an highly attenuative wort?

Would it lead to a full bodied wort?

If I wanted it to lean more dry/alttenuative (for a WCIPA) what adjustments should I make?

If I wanted to make it fuller bodied (for a NEIPA) what adjustments should I make?

Does a step in the 158-160 build dextrins and body the longer it goes?

Any other recommendations for mashing over night but still having some control over body?

This chart is a helpful point of reference