Hello all,

I have now started my 4th attempt to brew beer. In the first two my OG was always 1/3 lower than you should be according to the recipe. Mostly I have then compensated by less water.

Now I have planned on 6 gallons and used significantly more malt.

14.8 lb (6.75 kg) German Pilsner Malt

1.6 lb (750 g) Malted White Wheat 0.75

2 lb (900 g) Golden Candi Syrup

Original recipe

5 gallon (19 liter) batch

10 lb (4.5 kg) German Pilsner Malt

1 lb (450 g) Malted White Wheat

1 lb (450 g) Golden Candi Syrup (15 min.)

Target was an OG of 1.059, I was at 1.042 with 4 gallons. Way too low in my opinion.

About my mash process, I used a boil-in with BIAB (with a boiling machine) and tried to keep the temperature as close as possible.

Every 15 minutes I stirred the malt, total was 1 hour, 15 minutes in the pot.

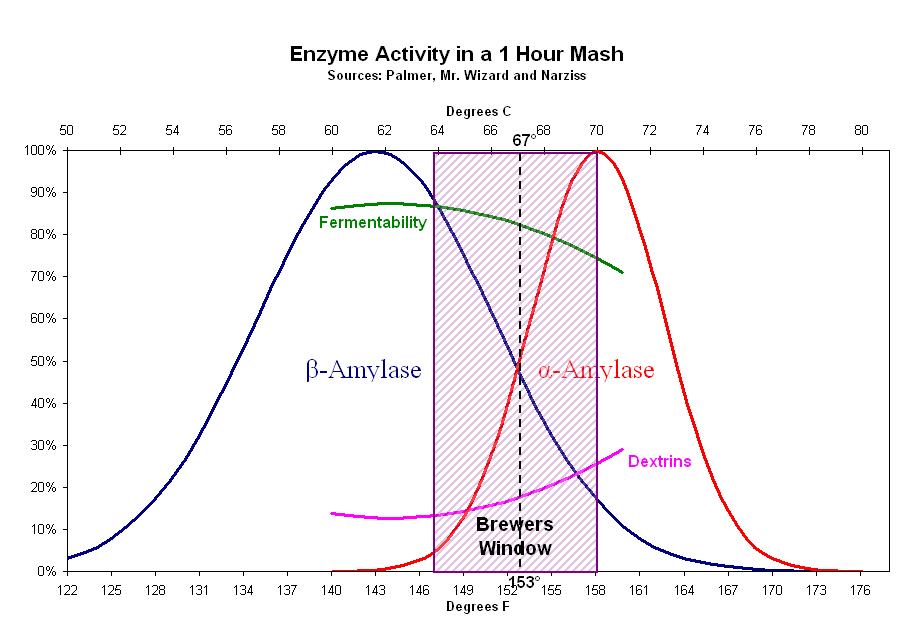

I started at 143F (62 °C) (first 15 minutes). The last half hour was at 158-163F (70-73°C).

Malt out, and boiled for 1 hour.

I let the bag of malt drip out for several hours, then added the remaining liquid.

Still only an OG of 1.042, can anyone tell me what I can do differently with my equipment? Thank you.

I have now started my 4th attempt to brew beer. In the first two my OG was always 1/3 lower than you should be according to the recipe. Mostly I have then compensated by less water.

Now I have planned on 6 gallons and used significantly more malt.

14.8 lb (6.75 kg) German Pilsner Malt

1.6 lb (750 g) Malted White Wheat 0.75

2 lb (900 g) Golden Candi Syrup

Original recipe

5 gallon (19 liter) batch

10 lb (4.5 kg) German Pilsner Malt

1 lb (450 g) Malted White Wheat

1 lb (450 g) Golden Candi Syrup (15 min.)

Target was an OG of 1.059, I was at 1.042 with 4 gallons. Way too low in my opinion.

About my mash process, I used a boil-in with BIAB (with a boiling machine) and tried to keep the temperature as close as possible.

Every 15 minutes I stirred the malt, total was 1 hour, 15 minutes in the pot.

I started at 143F (62 °C) (first 15 minutes). The last half hour was at 158-163F (70-73°C).

Malt out, and boiled for 1 hour.

I let the bag of malt drip out for several hours, then added the remaining liquid.

Still only an OG of 1.042, can anyone tell me what I can do differently with my equipment? Thank you.