outdoorvtguy

Active Member

I've been on these forums for a while and I looked at a bunch of the "coffin" builds for a keezer when I was building mine a few years ago.

I thought it might be beneficial to others to share the process by which I built the keezer that I have, the requirements and the actual build ( albeit without a lot of photos, I completed the main build a few years ago ).

Requirements :

1. Had to be able to hold atleast 4 kegs, ball-lock style, and be used for some lagering.

2. Had to be self-contained. No exterior CO2 bottles or fittings.

3. Had to look decent, no beat-up white freezers, and had to not attract a lot of attention to itself ( "Hey, look at me, the huge, white mass with all these taps! ).

4. Had to be easily reverseable in the future if I decided to stop brewing ( say it ain't so, one never knows ) or go bigger ( more likely ).

Because of these requirements, I immediately ruled out making one of the "collar" type keezers. They involved bolting on the collar and attaching things to the front if the freezer itself just as a drip tray.

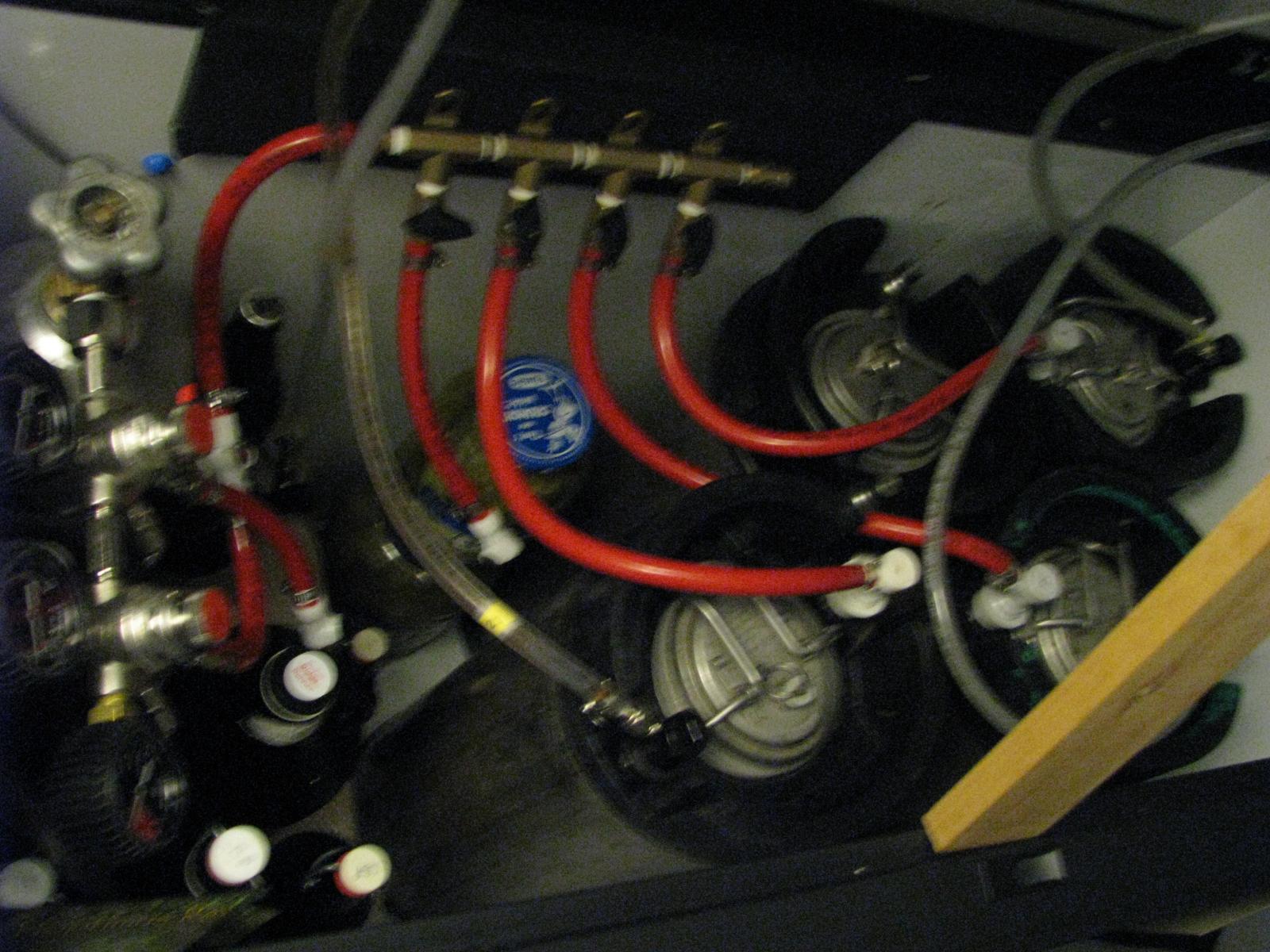

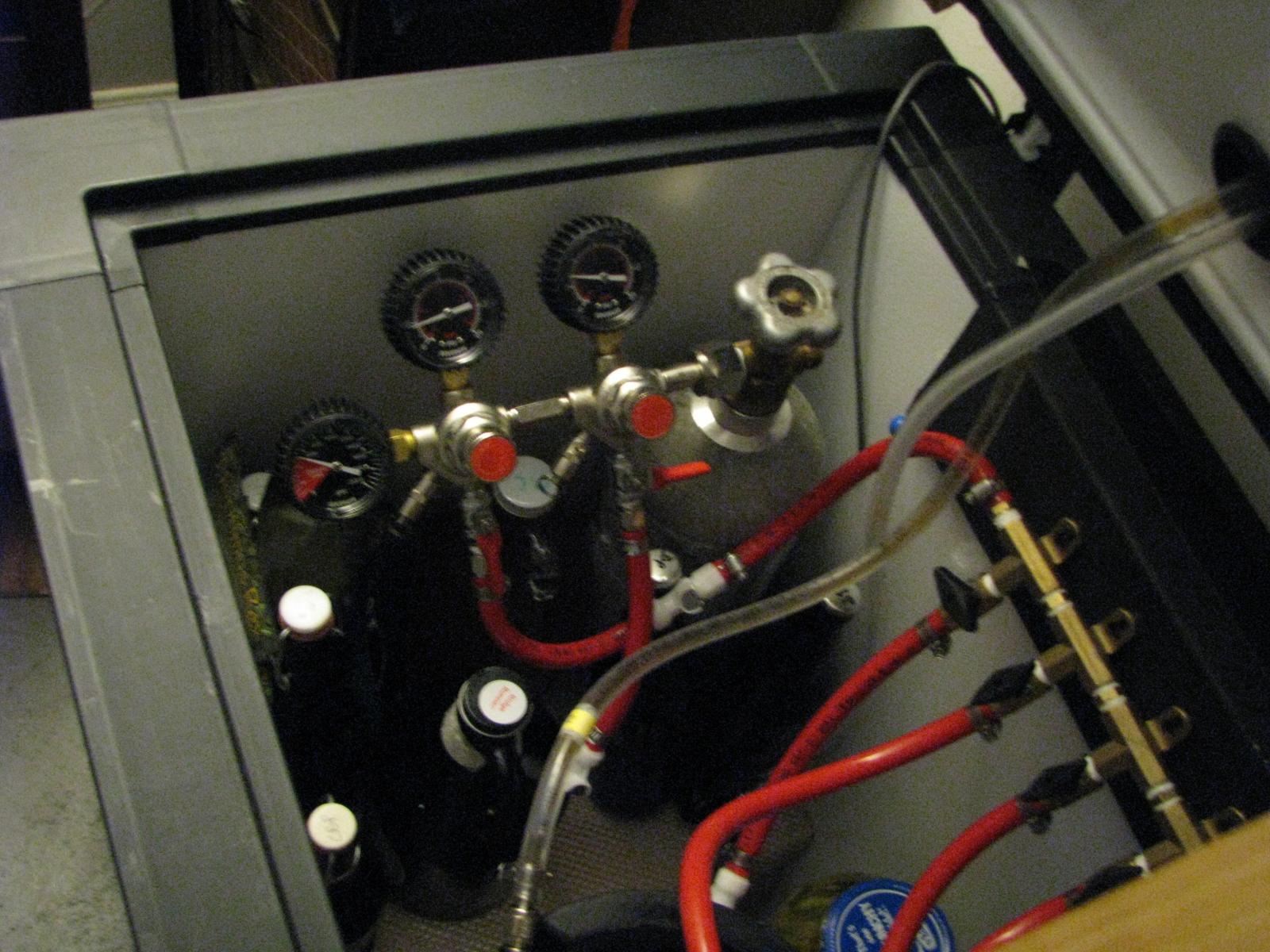

I decided I wanted the classic "towers" out of the top with drip trays that were easily cleaned. The CO2 container and fittings would be inside the freezer, on the "shelf" about the compressor.

The Build

I originally started looking in Craigslist and in the papers for a used Freezer, preferrably not white, for something in the 8-10 Cu FT range. Based on info I was able to find out there, that size seemed to be the sweet spot for what I wanted. I had no luck. Everything was either really huge and old or really small and new. Both seemed to have fairly high prices ( for the time ) and the difference between new and used was sometimes about $50.

So I decided to go new. I ordered an 8.8 cuft Kenmore Freezer in black for about $200. This freezer did have a locking top and a selectable "alarm" that would sound if the freezer got too warm. I could use it as-is with no real modifications. I selected a Ranco controller and fed the temp sensor through the back ( near the hinges ) with minimal impact to the seal.

Next was the top. This version of Freezer has a handle that bows out from the top, probably about 1/2 inch, so I made a top that slides on with a recess for the handle. It has a collar around 3 sides, open in the back. I made it using solid oak on the sides and finish plywood/oak veneer for the top. The top is fairly thick but, because it hooks around the handle, the top can still be opened normally with the top and towers attached. You just have to be aware of the proximity to the wall to prevent the towers from hitting it.

I originally started with 1 tower with the intent of going for 2. I added the second tower last year. I needed way to drill through the top of the cooler that would allow me to reverse it. I found 2" surrounds for holes that would normally be in a work desk. Perfect. I centered the first tower off the center line and drilled a 2 inch hole through the top of the freezer and then used the surround to clean up the edge, on both the metal and the plastic top. I drilled a corresponding hole in the wood top and then bolted/screwed on the tower.

This setup allowed me to open the top with the tower still attached to get easy access to the kegs etc but it also allowed me to remove the top/tower completely and just plug the holes and I could the use the freezer as a freezer ( or sell it as such ).

As far as mobility, I decided to build a base that the keezer would sit on with wheels that I could use until I decided on it's final "home". It was also painted black and allowed me to push the keezer away from the wall to open it. I've since removed it ( the keezer just sat on top of it, not fastened ) because I didn't have a need to move it in it's current location.

Things you should really have in a Keezer

In the process of building this, I came up with some essential things you need to have for any keezer that are best done right from the start :

- If you are thinking of having more than 1 keg, get a dual regulator. Having the ability to force carb or serve at multiple pressures is a must. At the least, having the ability to have a keg of root beer in there ( requires higher pressure ) will justify the keezer to the wife/kids.

- Get the line lengths for your taps correct up front. Base the line length on the shortest you would need and then add a few inches. Sure, it may come out slow for some types of beer but at least you will be matching the carbonation. There are many calculators out there that take a lot of the guesswork out of figuring this out, just search for them.

- Get the 1/4 inch flare fittings, not the barbs, for atleast the liquid ends for your ball/pin lock kegs. Cleaning the lines with something that you can disassemble rather than yank apart is a very good thing. Also, for force carbonation, you can just to swap the gas head for a liquid head, it takes about 2 minutes.

- Quick disconnects are your friend. Having the ability to pull the CO2 keg without having the fiddle with a barbed connection is a must.

- Get the best taps you can afford. If you think you will be doing this for a while, get a few really good taps as a opposed to a mess of questionable ones. Stainless steel perlicks are one of the best you can buy and they are easily disassembled for cleaning and drip very little. I read a few horror stories about taps leaking or being hard to clean so I bought what most said were the best taps.

I am sure there are other things that could be added on to this list and I am in no way an expert here. A lot of this stuff I learned through trial and error ( anyone want a bunch of 1/4 barbed ball lock liquid heads? ) and just though it might be nice to share. I hope that this can help out some folks.

I will have pictures to follow, need to take using another device as it is easier to transfer.

I thought it might be beneficial to others to share the process by which I built the keezer that I have, the requirements and the actual build ( albeit without a lot of photos, I completed the main build a few years ago ).

Requirements :

1. Had to be able to hold atleast 4 kegs, ball-lock style, and be used for some lagering.

2. Had to be self-contained. No exterior CO2 bottles or fittings.

3. Had to look decent, no beat-up white freezers, and had to not attract a lot of attention to itself ( "Hey, look at me, the huge, white mass with all these taps! ).

4. Had to be easily reverseable in the future if I decided to stop brewing ( say it ain't so, one never knows ) or go bigger ( more likely ).

Because of these requirements, I immediately ruled out making one of the "collar" type keezers. They involved bolting on the collar and attaching things to the front if the freezer itself just as a drip tray.

I decided I wanted the classic "towers" out of the top with drip trays that were easily cleaned. The CO2 container and fittings would be inside the freezer, on the "shelf" about the compressor.

The Build

I originally started looking in Craigslist and in the papers for a used Freezer, preferrably not white, for something in the 8-10 Cu FT range. Based on info I was able to find out there, that size seemed to be the sweet spot for what I wanted. I had no luck. Everything was either really huge and old or really small and new. Both seemed to have fairly high prices ( for the time ) and the difference between new and used was sometimes about $50.

So I decided to go new. I ordered an 8.8 cuft Kenmore Freezer in black for about $200. This freezer did have a locking top and a selectable "alarm" that would sound if the freezer got too warm. I could use it as-is with no real modifications. I selected a Ranco controller and fed the temp sensor through the back ( near the hinges ) with minimal impact to the seal.

Next was the top. This version of Freezer has a handle that bows out from the top, probably about 1/2 inch, so I made a top that slides on with a recess for the handle. It has a collar around 3 sides, open in the back. I made it using solid oak on the sides and finish plywood/oak veneer for the top. The top is fairly thick but, because it hooks around the handle, the top can still be opened normally with the top and towers attached. You just have to be aware of the proximity to the wall to prevent the towers from hitting it.

I originally started with 1 tower with the intent of going for 2. I added the second tower last year. I needed way to drill through the top of the cooler that would allow me to reverse it. I found 2" surrounds for holes that would normally be in a work desk. Perfect. I centered the first tower off the center line and drilled a 2 inch hole through the top of the freezer and then used the surround to clean up the edge, on both the metal and the plastic top. I drilled a corresponding hole in the wood top and then bolted/screwed on the tower.

This setup allowed me to open the top with the tower still attached to get easy access to the kegs etc but it also allowed me to remove the top/tower completely and just plug the holes and I could the use the freezer as a freezer ( or sell it as such ).

As far as mobility, I decided to build a base that the keezer would sit on with wheels that I could use until I decided on it's final "home". It was also painted black and allowed me to push the keezer away from the wall to open it. I've since removed it ( the keezer just sat on top of it, not fastened ) because I didn't have a need to move it in it's current location.

Things you should really have in a Keezer

In the process of building this, I came up with some essential things you need to have for any keezer that are best done right from the start :

- If you are thinking of having more than 1 keg, get a dual regulator. Having the ability to force carb or serve at multiple pressures is a must. At the least, having the ability to have a keg of root beer in there ( requires higher pressure ) will justify the keezer to the wife/kids.

- Get the line lengths for your taps correct up front. Base the line length on the shortest you would need and then add a few inches. Sure, it may come out slow for some types of beer but at least you will be matching the carbonation. There are many calculators out there that take a lot of the guesswork out of figuring this out, just search for them.

- Get the 1/4 inch flare fittings, not the barbs, for atleast the liquid ends for your ball/pin lock kegs. Cleaning the lines with something that you can disassemble rather than yank apart is a very good thing. Also, for force carbonation, you can just to swap the gas head for a liquid head, it takes about 2 minutes.

- Quick disconnects are your friend. Having the ability to pull the CO2 keg without having the fiddle with a barbed connection is a must.

- Get the best taps you can afford. If you think you will be doing this for a while, get a few really good taps as a opposed to a mess of questionable ones. Stainless steel perlicks are one of the best you can buy and they are easily disassembled for cleaning and drip very little. I read a few horror stories about taps leaking or being hard to clean so I bought what most said were the best taps.

I am sure there are other things that could be added on to this list and I am in no way an expert here. A lot of this stuff I learned through trial and error ( anyone want a bunch of 1/4 barbed ball lock liquid heads? ) and just though it might be nice to share. I hope that this can help out some folks.

I will have pictures to follow, need to take using another device as it is easier to transfer.