HBrew71

Well-Known Member

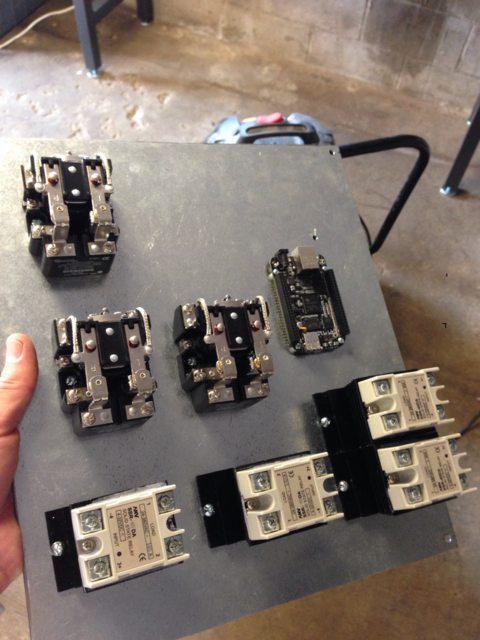

Hello Everybody! I was wondering what you guys are using for the control panel box. How are you mounting the pi in it? My panel will have the pi, one SainSmart 8-channel relay board, and 24V transformer for the valves. How are you making the connections more persistent? Are you using the breadboard or something else? Thanks for any help in advance!