armymedic942

Well-Known Member

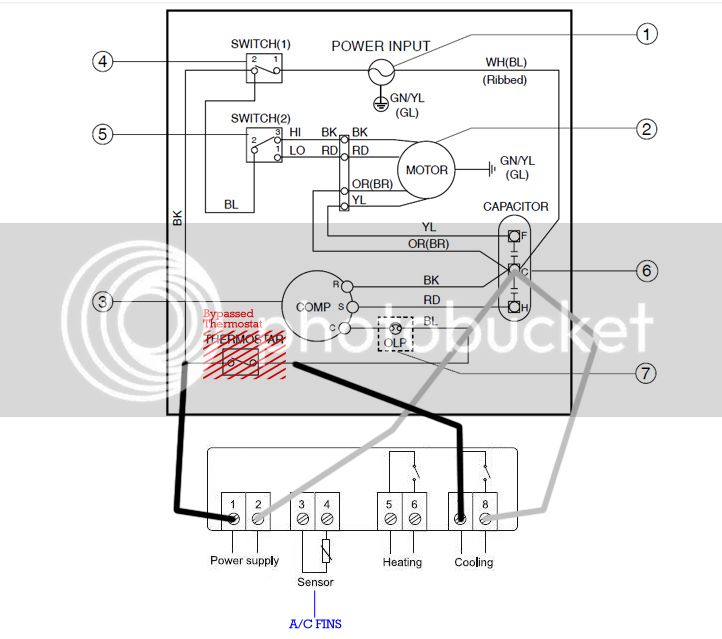

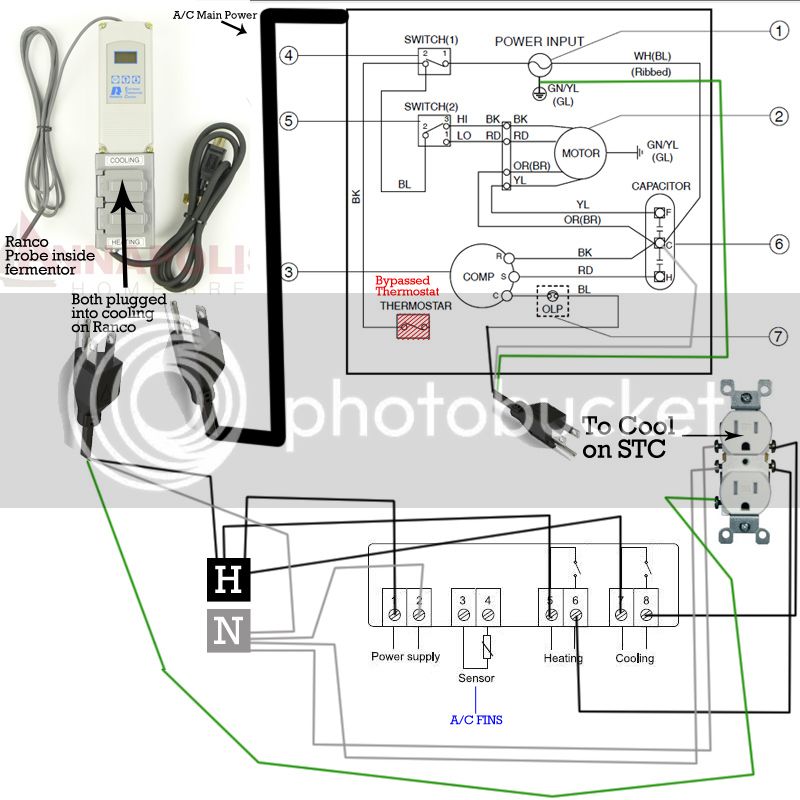

That 3rd picture is the window. I haven't put the outer cladding on yet. There is no fridge. The first version was built around a bar fridge and I used the door on the side of the chamber. The fridge couldn't even keep the interior temp below 70, because it had internal evaporation coils that radiated heat inside the chamber. So I switched to the AC design after seeing your thread. I ended up moving the AC unit to the other end because it is farther from the door. The box itself is very well insulated. I used styrofoam panels with reflective coating on the inside, covered with pink bat, and spray foamed all the joints. The only air loss is the door, which i am going to solve with weather strip (I live in Canada so it's not hard to come by).

So I have run the system for 1 hour and it has taken the interior temp from 70 down to 50! SUCESS! Thank you very much. Maybe I will name my next lager after you!

So I have run the system for 1 hour and it has taken the interior temp from 70 down to 50! SUCESS! Thank you very much. Maybe I will name my next lager after you!