a cool thing would be to make a pattern or design using barley kernels and glaze it to the wood. idk if it would rot though. I just thought of that after seeing those tubes. coming along well. I'll see if you lose your sanity after this project before I decide to do it

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Electric Brewery Build!

- Thread starter jbsengineer

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

jbsengineer

Well-Known Member

a cool thing would be to make a pattern or design using barley kernels and glaze it to the wood. idk if it would rot though. I just thought of that after seeing those tubes. coming along well. I'll see if you lose your sanity after this project before I decide to do it

My uncle is an artist. I plan on bringing him over and talking over a few possibilities. He can do some pretty amazing things with wood carving, drawing, painting, etc. Who knows,

rockinmarty

Big Member

By the Jbs did you buy your screws in Canada or do they finally sell robertson screws in the USA.

jbsengineer

Well-Known Member

By the Jbs did you buy your screws in Canada or do they finally sell robertson screws in the USA.

Nope, they are grip-rites from Lowes. Expensive, but I like the stainless and square heads:

GripRite

I like the grain tube! I would mix in some whole hops. Nice work!

P.S. It's all about TORX screws now. Square drive is so 90's

Edit...you could put in pellet hops but then it would look way too much like a rodent feed tube

P.S. It's all about TORX screws now. Square drive is so 90's

Edit...you could put in pellet hops but then it would look way too much like a rodent feed tube

I want to be you. Haha

I started out trying to rush into a crappy single kettle version of Kals build but decided to just do the real thing on a much longer timeline. It may take 2 years to gather the components but at least my wife wont smother me with a pillow in my sleep. Glad yours is more supportive!

Glad yours is more supportive!

The Blichmans are so shiny....

I started out trying to rush into a crappy single kettle version of Kals build but decided to just do the real thing on a much longer timeline. It may take 2 years to gather the components but at least my wife wont smother me with a pillow in my sleep.

The Blichmans are so shiny....

jbsengineer

Well-Known Member

i don't recall if you ever talked about this, is it going to be a rims or herms

herms

kpr121

Well-Known Member

Looking awesome! I love the style of the brewstand/hood.

Got a question: Whats the height from the floor to the top of the kettles? I am planning out my stand and didnt know if there is a standard height everyone uses or do you just go by what feels right.

Got a question: Whats the height from the floor to the top of the kettles? I am planning out my stand and didnt know if there is a standard height everyone uses or do you just go by what feels right.

That is looking great can't wait to see how it all looks completed!

rockinmarty

Big Member

Nope, they are grip-rites from Lowes. Expensive, but I like the stainless and square heads:

GripRite

thats pretty much all we use up here on the other side of the border. those are expensive but you know as soon as you put the word stainless somewhere it doubles the price. And they are about the same price up here

rockinmarty

Big Member

i use the star bit or philips. never seen a square head before.

mendozer just cross over to Vancouver and thats mostly what you'll see. those are a Canadian invention

kal

Well-Known Member

Yup! They're called "Robertson" style:

Go Canada!

Kal

Go Canada!

Kal

rockinmarty

Big Member

Thanks for joining in this little Hijack Kal.

Nice set of well used screwdriver.

We now return this thread to jbs and Go Canada!

Nice set of well used screwdriver.

We now return this thread to jbs and Go Canada!

jbsengineer

Well-Known Member

Installed 8' fluorescent lights tonight!

CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

looking stellar man! Funny because I grew up in potsdam, ny near canada and those square heads were everywhere since we were so close to canada.

er um sorry for the re-hijack!

It is funny, I keep thinking my build will turn a corner, but then I realize how much more there is to do. But you know what, even half built it was more fun to brew on than my first controller

er um sorry for the re-hijack!

It is funny, I keep thinking my build will turn a corner, but then I realize how much more there is to do. But you know what, even half built it was more fun to brew on than my first controller

CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

Hey man - check out post #252. Not sure which way you are going on your coil/chiller, but thought I would let you know the route I am taking and maybe if needed you could borrow the bender jig. Hope the rest is well!

Goocher

Well-Known Member

Subscribed. Looks awesome! Keep up the good work!

jeffb418

Well-Known Member

sub'ed

jbsengineer

Well-Known Member

Ok, this past month I have been extremely busy at work, at home, and working on the brewery. Sorry for the lack of posts.

This week I will be sure to post all the photos from the past 4 weeks.

On a good note, it's almost complete. I started wiring on the inside of the panel and hope to be finished with that by the weekend.

I was able to finish the ventilation this past Saturday. Ended up reducing down to 4" immediately and ducting directly out above the sink:

This week I will be sure to post all the photos from the past 4 weeks.

On a good note, it's almost complete. I started wiring on the inside of the panel and hope to be finished with that by the weekend.

I was able to finish the ventilation this past Saturday. Ended up reducing down to 4" immediately and ducting directly out above the sink:

kal

Well-Known Member

Some hints:

- I would have put the reducer at the output wall if a reduce is required so that the duct as 6" as long as possible.

- You've got what appears to be four 90 degree elbows there. You only need 2. Less elbows means better airflow. A straight piece out of the fan all the way to where the wall hole is, followed by two 90 degree elbows and then another straight piece.

Kal

- I would have put the reducer at the output wall if a reduce is required so that the duct as 6" as long as possible.

- You've got what appears to be four 90 degree elbows there. You only need 2. Less elbows means better airflow. A straight piece out of the fan all the way to where the wall hole is, followed by two 90 degree elbows and then another straight piece.

Kal

jbsengineer

Well-Known Member

Some hints:

- I would have put the reducer at the output wall if a reduce is required so that the duct as 6" as long as possible.

- You've got what appears to be four 90 degree elbows there. You only need 2. Less elbows means better airflow. A straight piece out of the fan all the way to where the wall hole is, followed by two 90 degree elbows and then another straight piece.

Kal

I was hoping you would chyme in.

I agree with your suggestions. I plan to modify it if my airflow is not adequate. Althought more flow can't hurt so I will probably add it to the "post inaugural brew to do list."

Any thoughts on the position of the fan?

kal

Well-Known Member

I don't think the position of the fan matters. Put it where is convenient, especially if draining is required.

Kal

Kal

jbsengineer

Well-Known Member

Brewery is online.

I'm going to take a step backwards in thread (before the ventalation was completed) and follow up with photos from the last couple months of building.

Here is the area all cleaned up. This is before I started the kettle work and panel. You can see all the boxes underneath which house all the plumbing and ductwork.

I plan to in the future add two more 4' flourescents that will be perpendicular to the 8'.

I'm going to take a step backwards in thread (before the ventalation was completed) and follow up with photos from the last couple months of building.

Here is the area all cleaned up. This is before I started the kettle work and panel. You can see all the boxes underneath which house all the plumbing and ductwork.

I plan to in the future add two more 4' flourescents that will be perpendicular to the 8'.

jbsengineer

Well-Known Member

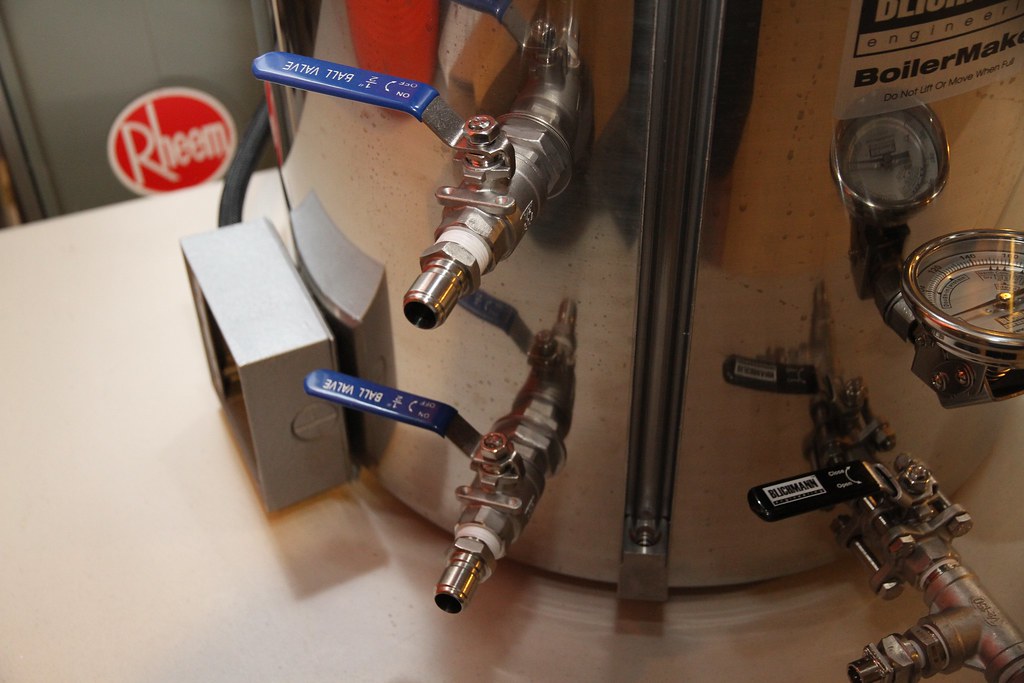

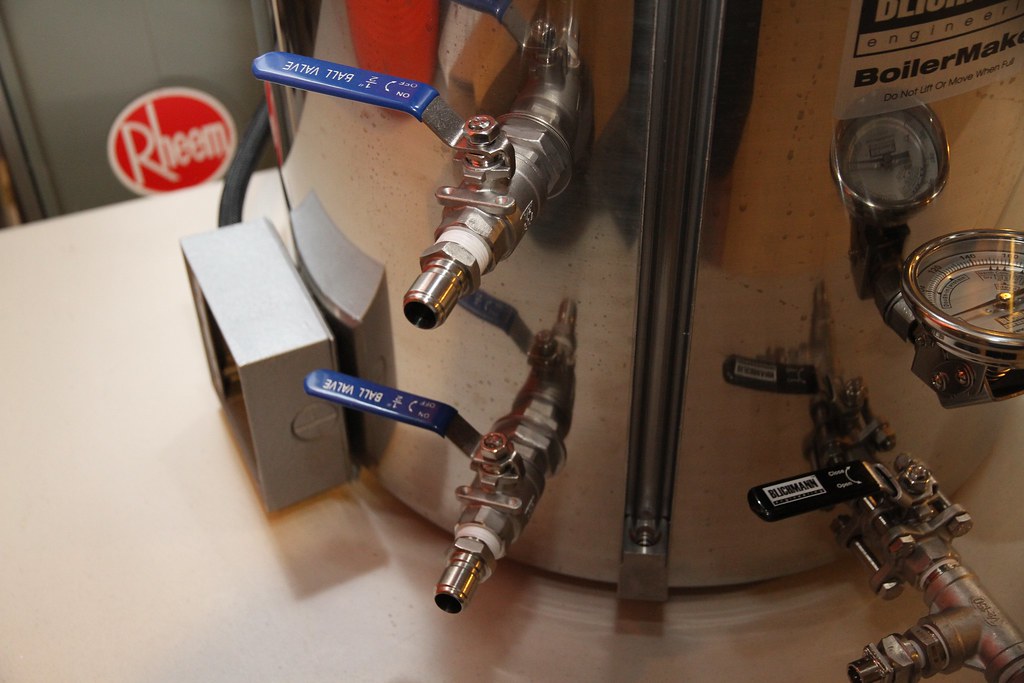

Putting holes into the new and shiny Blichmanns was hard to do. I tested it on a couple pieces of sheet metal first.

I found the best method was to take a nail or screw and make a small dent, use the greenlee step bit until the greelee punch could just fit into the hole. It was a bit nerve wrenching at first.

Leak testing the boil kettle:

Mash Tun:

I found the best method was to take a nail or screw and make a small dent, use the greenlee step bit until the greelee punch could just fit into the hole. It was a bit nerve wrenching at first.

Leak testing the boil kettle:

Mash Tun:

jbsengineer

Well-Known Member

Had to modify Kal's pump stand a bit to accomodate the chugger pumps inline design:

jbsengineer

Well-Known Member

The kettles as a whole were pretty easy. I struggled a bit with the HLT coil (getting it installed) but then I just trimmed the coil a bit and it fit nicely. However the spacing between the two ball valve makes the Blichmann temperature probe just barely fit.

Finished kettles:

Finished kettles:

jbsengineer

Well-Known Member

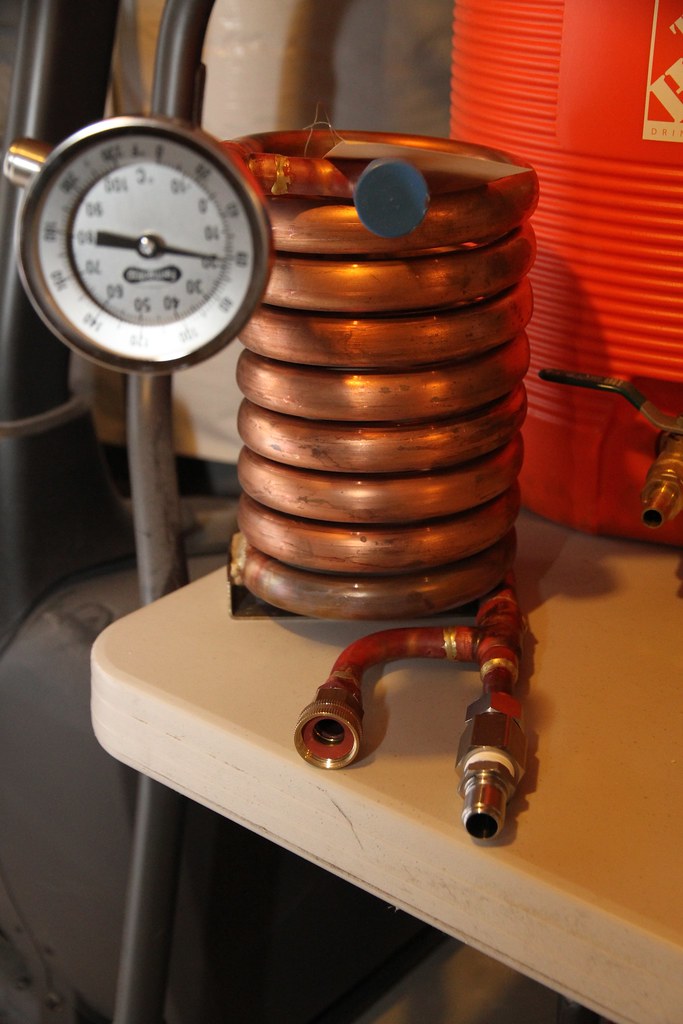

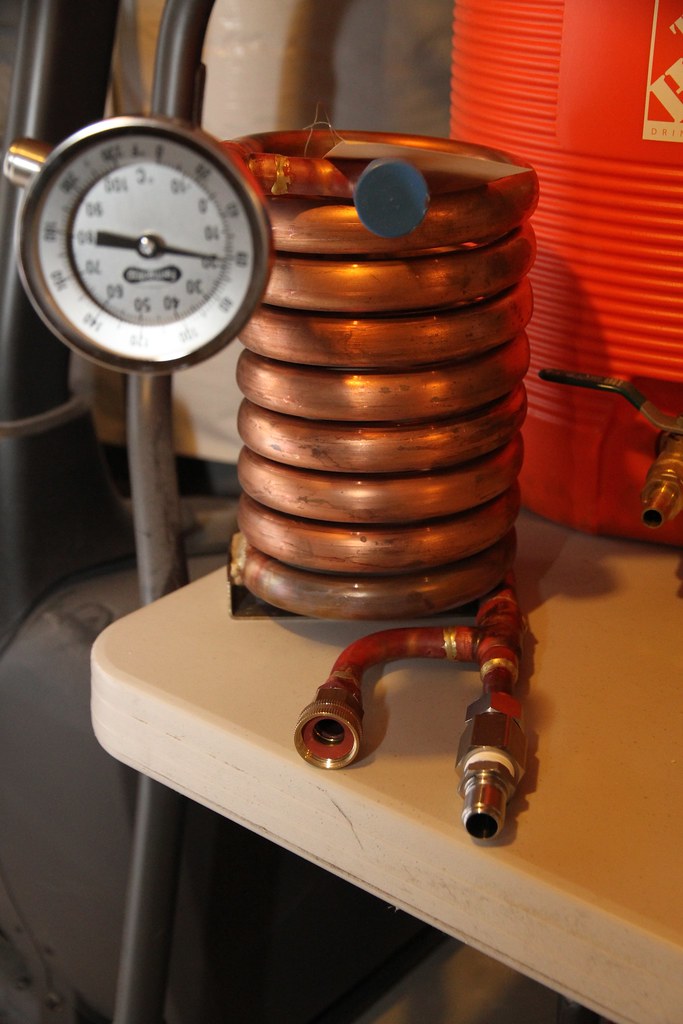

Chiller:

CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

Nice! Pretty soon you are gonna be burning up some of your grain

Let me know how that chiller works out for you. I reshaped my copper chiller to be wider and now I am getting 11G of boiling worts chilled to 130F in 3 minutes!! I was going to go convoluted CF chiller like the one you have (or at least it looks like one), now I am not so sure.

Let me know how that chiller works out for you. I reshaped my copper chiller to be wider and now I am getting 11G of boiling worts chilled to 130F in 3 minutes!! I was going to go convoluted CF chiller like the one you have (or at least it looks like one), now I am not so sure.

Wow! Just nice...except your chiller guage is upside down Otherwise, awesome!

Otherwise, awesome!

jbsengineer

Well-Known Member

Nice! Pretty soon you are gonna be burning up some of your grain

Let me know how that chiller works out for you. I reshaped my copper chiller to be wider and now I am getting 11G of boiling worts chilled to 130F in 3 minutes!! I was going to go convoluted CF chiller like the one you have (or at least it looks like one), now I am not so sure.

It has been far to long without brewing any beer. I have a backlog of grain as you know! I chose to invest any free time into getting the brewery online. First batch is this weekend. Keeping it easy with a Amber Ale.

Will do. I did a test run with 160F water and it chilled easily to 70F coming out. Still need to do a test run of the boiling water.

jbsengineer

Well-Known Member

Wow! Just nice...except your chiller guage is upside downOtherwise, awesome!

Actually the chiller is. I have a picture of it mounted.

I hope to post another set of photos later today or tonight!

Fly_Rodder

Well-Known Member

I did a final test run last night from boil and it was the first time I got my chiller dialed into 70F quickly. It's a bit of game to get max flow while maintaining a consistent temp. Excellent chiller though. It's a little wobbly at the bottom and I don't quite trust the compression fittings - but I haven't had any leaks yet and nothing has fallen off or bent - so, time for beer making. :rockin:It has been far to long without brewing any beer. I have a backlog of grain as you know! I chose to invest any free time into getting the brewery online. First batch is this weekend. Keeping it easy with a Amber Ale.

Will do. I did a test run with 160F water and it chilled easily to 70F coming out. Still need to do a test run of the boiling water.

jbsengineer

Well-Known Member

Nice! Pretty soon you are gonna be burning up some of your grain

Let me know how that chiller works out for you. I reshaped my copper chiller to be wider and now I am getting 11G of boiling worts chilled to 130F in 3 minutes!! I was going to go convoluted CF chiller like the one you have (or at least it looks like one), now I am not so sure.

I did a test run with water tonight. From boiling I was able to move 12.3G down to 66 degrees in 11minutes.

Water temp is 53 degrees, so that gives me a good amount of flexibility.

Fly_Rodder

Well-Known Member

Are you using the Hop Stopper that Kal recommends? If you are, then plain water won't give you issues when draining the kettle for chilling. When he says that you have to slow the output to a trickle once the stopper is exposed to air, he means it. I found out the hard way when I drained the BK and slurp siphon was lost and I left about 2.5 gallons in the BK.I did a test run with water tonight. From boiling I was able to move 12.3G down to 66 degrees in 11minutes.

Water temp is 53 degrees, so that gives me a good amount of flexibility.

Chilling with a Hop Stopper takes a bit longer - upwards of 30 minutes.

CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

Are you using the Hop Stopper that Kal recommends? If you are, then plain water won't give you issues when draining the kettle for chilling. When he says that you have to slow the output to a trickle once the stopper is exposed to air, he means it. I found out the hard way when I drained the BK and slurp siphon was lost and I left about 2.5 gallons in the BK.

Chilling with a Hop Stopper takes a bit longer - upwards of 30 minutes.

See comments like this make me think the IC might be a better tool for me.

Start temp for my well water (usually 54F ish)

For an 11G batch:

1. just over 3 minutes to get to 130F or less.

2. ~15mins total to reach low to mid 70's

3. 18 mins to chill into 60's

Then I can just whirpool and let the hot break and hop fall, then drain.

jbsengineer

Well-Known Member

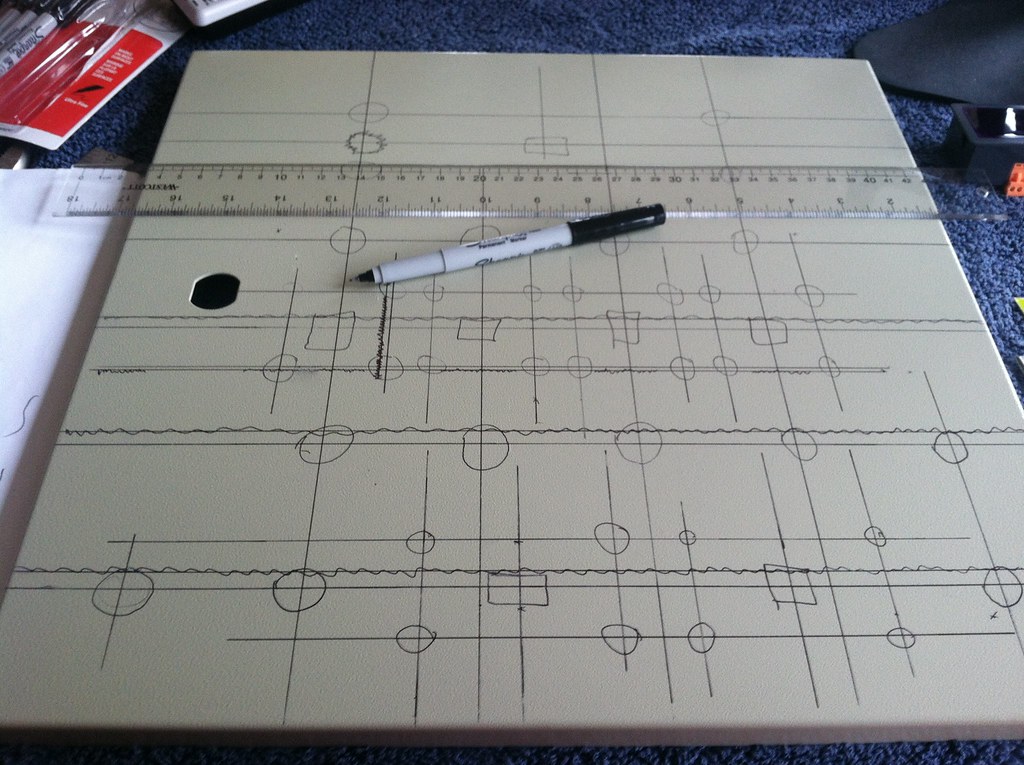

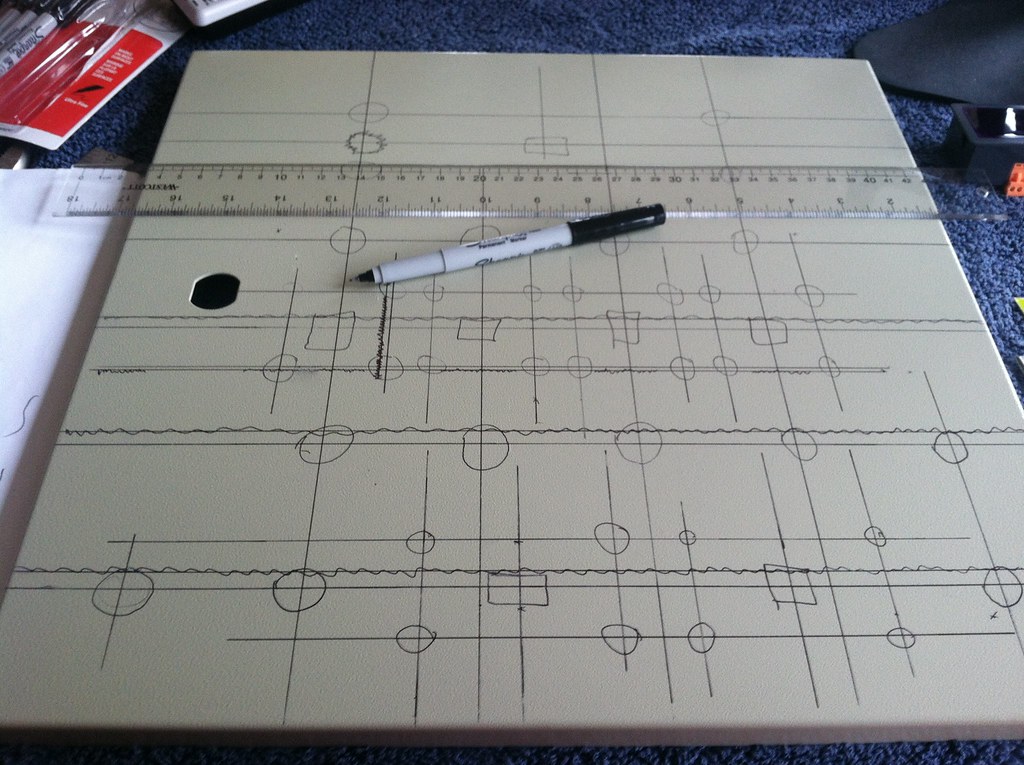

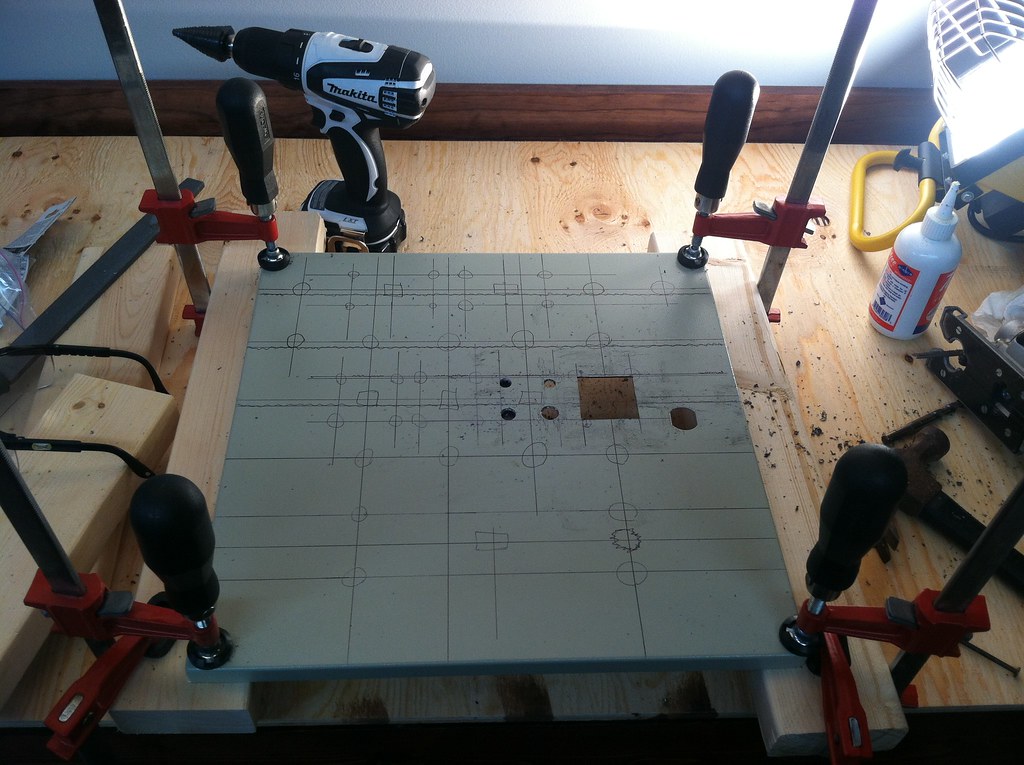

Drawing out the cut lines:

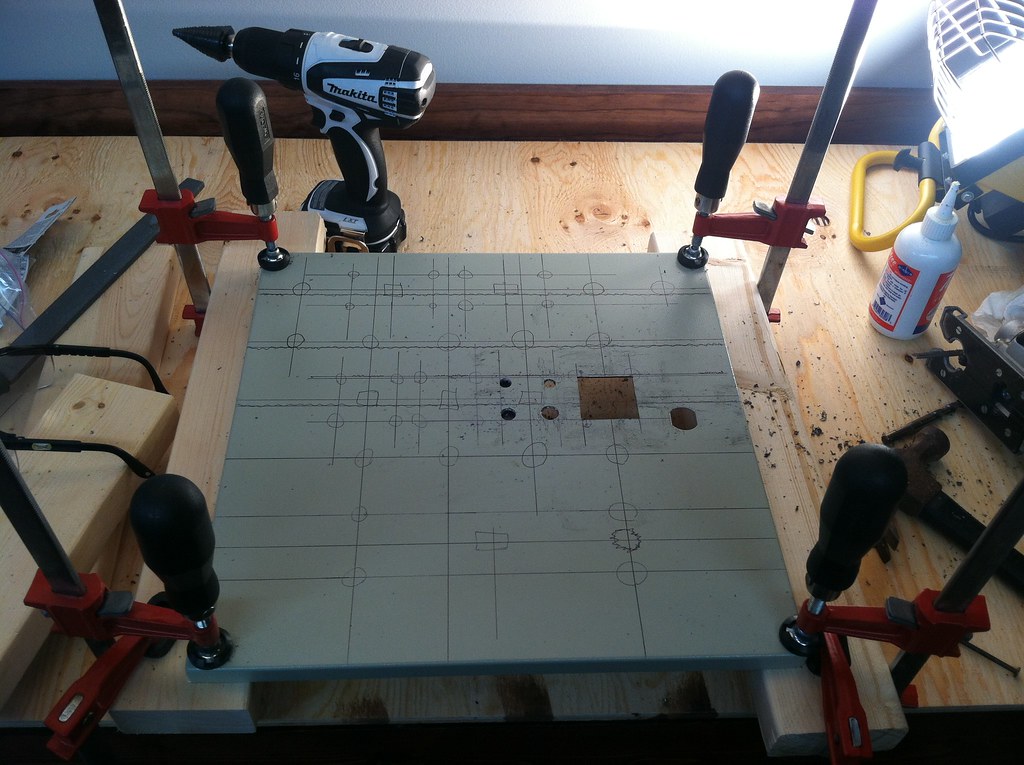

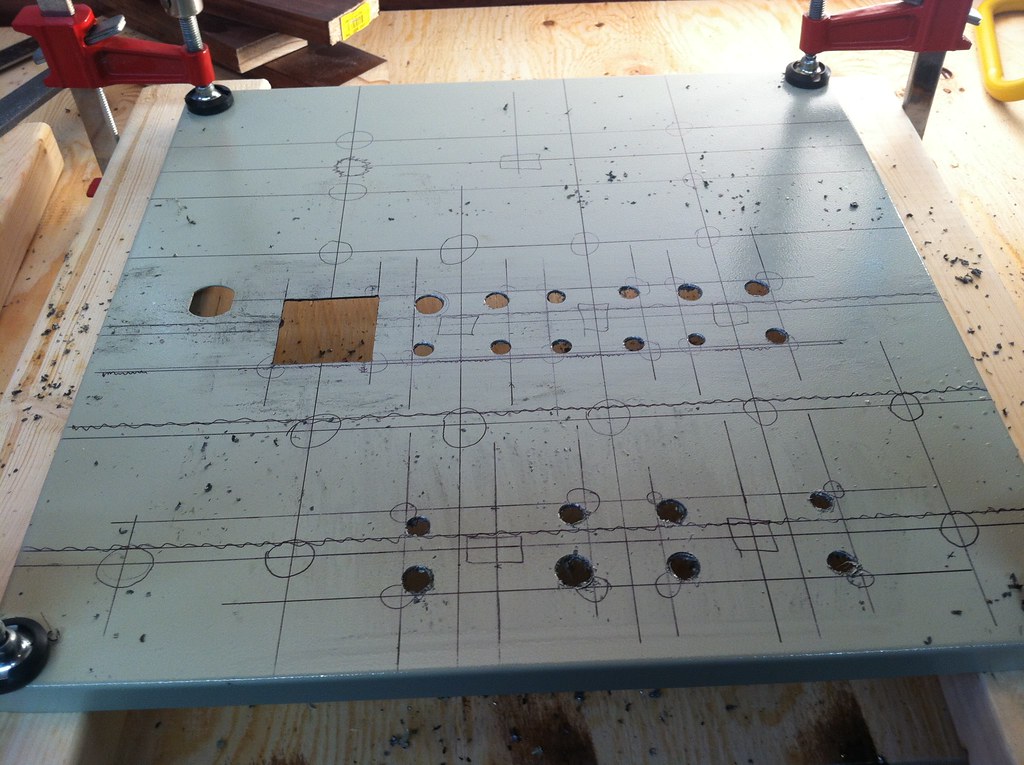

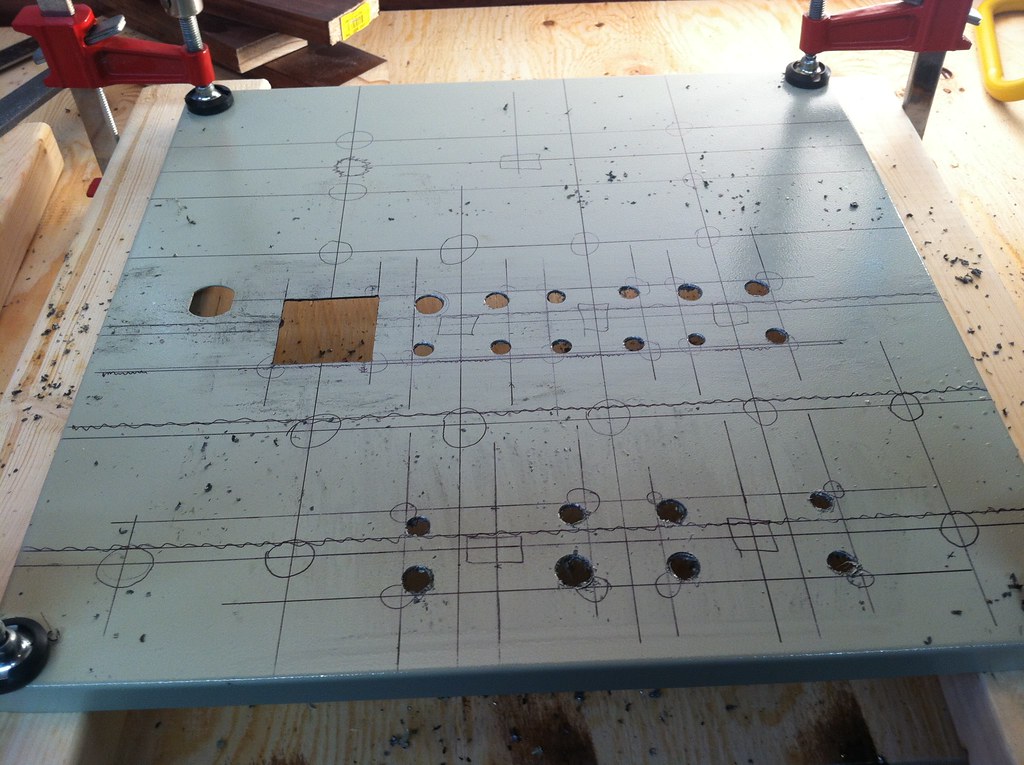

Slow but rewarding process. I'm really glad I installed a TV downstairs. Kept me entertained while I dodged metal shavings flying at me:

Ended up using the same punch on the XLR holes that I did for the 22mm lights and switches. Just needed to file some notches:

Slow but rewarding process. I'm really glad I installed a TV downstairs. Kept me entertained while I dodged metal shavings flying at me:

Ended up using the same punch on the XLR holes that I did for the 22mm lights and switches. Just needed to file some notches:

Similar threads

- Replies

- 0

- Views

- 136

- Replies

- 4

- Views

- 595

- Replies

- 10

- Views

- 2K

- Replies

- 3

- Views

- 1K