MuddyCreek

Well-Known Member

You're right Bronco, except that when I'm transferring to the BK, I only ultimately need about a 35 or 40 degree rise and I've got elements and gas-fired heat helping me as well.

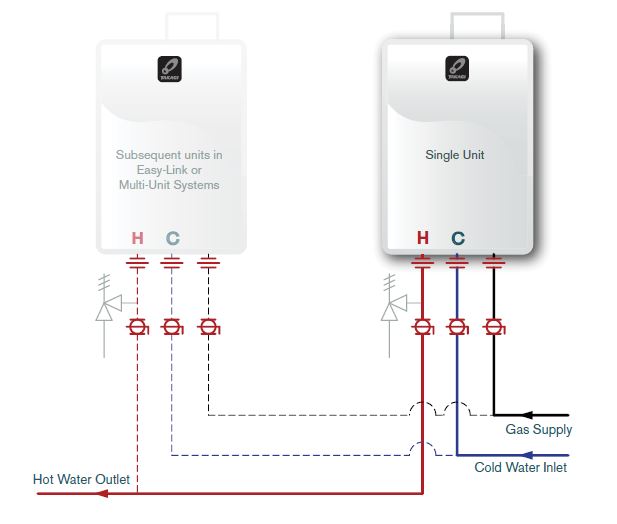

The water coming from the tankless into the HLT can come in under the strike temperature (around 160 to 166 depending on amount of grain and mash volume and grain temp, and heat up from there.) I also have elements and direct fire under the HLT to help heat that liquor up as necessary.) Coming IN to the HLT I can afford to take more time filling, I can use up my regular hot-water tank for the first unit and I can 're-use' hot water through the tankless to help things along.

Once I have my mash finished, I heat it up to mash-out by heating the HLT with the elements, tankless and direct-fire so I can heat the mash to the appropriate mash-out temp. Then I transfer the wort to the BK. As soon as the wort hits the BK I turn on the direct-fire and maintain the temp on the wort. As soon as it covers the lower elements I fire them up as well. I begin my sparge with the already heated liquor from my HLT and when I'm done with that I transfer that over as well to my BK. From there, I have all my elements and my direct fire going to heat my BK wort up. I also switch my transfer hose over to my tankless to the BK wort can go through the tankless and up the temp from 160 or 166 to say 190 or the max of 195. I set the flow volume on the tankless down a bit so the wort can heat better and turn on the pump to let the wort flow through the tankless. That allows me to heat wort through the elements, the direct fire and the tankless all at the same time. Now I'm only heating the wort about 35 or 40 degrees which reduces my BTU requirements significantly.

This brings the wort coming out of the tankless up to 190 or 195, which lowers my delta to boil down to around 10 or 15 degrees. (Boiling temp at our altitude is about 204.) When running properly we should be able to pump about 10 or so gpm at that temperature so it should take about 30 minutes. All that time our elements and direct fire are also heating the wort so we should be pretty close by then to boil.

That's the plan anyway. We'll continue to work with it and see how it goes. On the positive end the Clementine I brewed on Saturday came out right on the numbers so that's nice.

The water coming from the tankless into the HLT can come in under the strike temperature (around 160 to 166 depending on amount of grain and mash volume and grain temp, and heat up from there.) I also have elements and direct fire under the HLT to help heat that liquor up as necessary.) Coming IN to the HLT I can afford to take more time filling, I can use up my regular hot-water tank for the first unit and I can 're-use' hot water through the tankless to help things along.

Once I have my mash finished, I heat it up to mash-out by heating the HLT with the elements, tankless and direct-fire so I can heat the mash to the appropriate mash-out temp. Then I transfer the wort to the BK. As soon as the wort hits the BK I turn on the direct-fire and maintain the temp on the wort. As soon as it covers the lower elements I fire them up as well. I begin my sparge with the already heated liquor from my HLT and when I'm done with that I transfer that over as well to my BK. From there, I have all my elements and my direct fire going to heat my BK wort up. I also switch my transfer hose over to my tankless to the BK wort can go through the tankless and up the temp from 160 or 166 to say 190 or the max of 195. I set the flow volume on the tankless down a bit so the wort can heat better and turn on the pump to let the wort flow through the tankless. That allows me to heat wort through the elements, the direct fire and the tankless all at the same time. Now I'm only heating the wort about 35 or 40 degrees which reduces my BTU requirements significantly.

This brings the wort coming out of the tankless up to 190 or 195, which lowers my delta to boil down to around 10 or 15 degrees. (Boiling temp at our altitude is about 204.) When running properly we should be able to pump about 10 or so gpm at that temperature so it should take about 30 minutes. All that time our elements and direct fire are also heating the wort so we should be pretty close by then to boil.

That's the plan anyway. We'll continue to work with it and see how it goes. On the positive end the Clementine I brewed on Saturday came out right on the numbers so that's nice.