Mike123

Well-Known Member

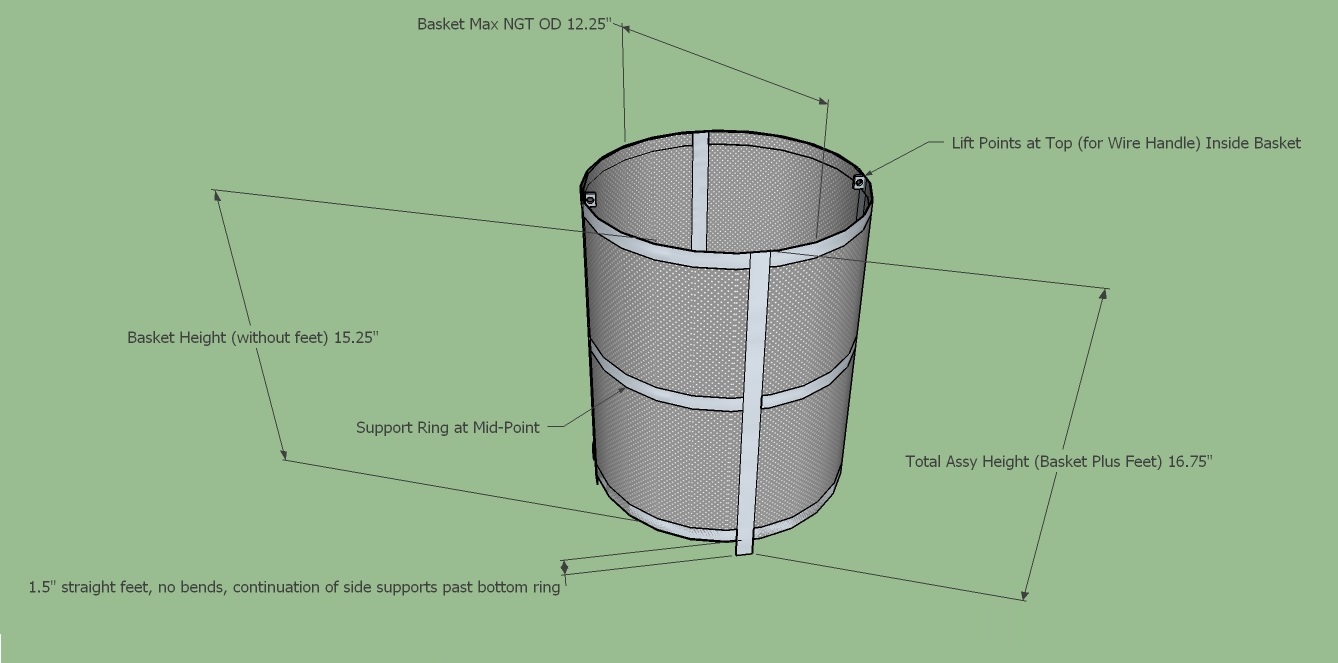

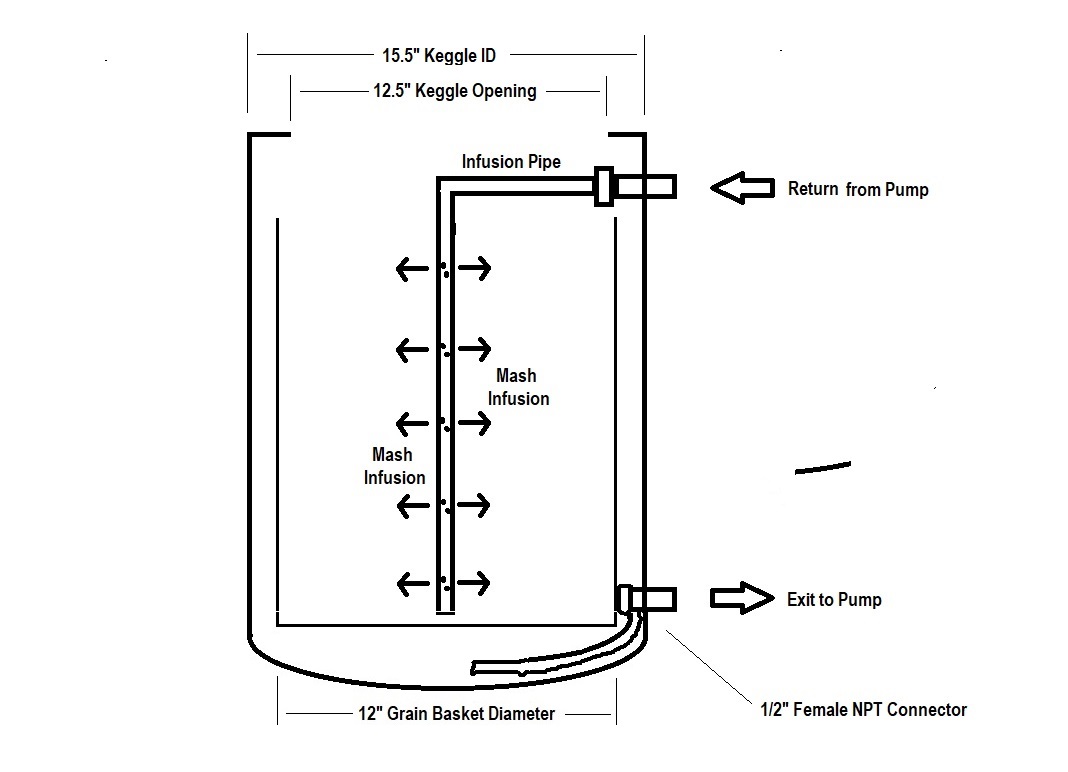

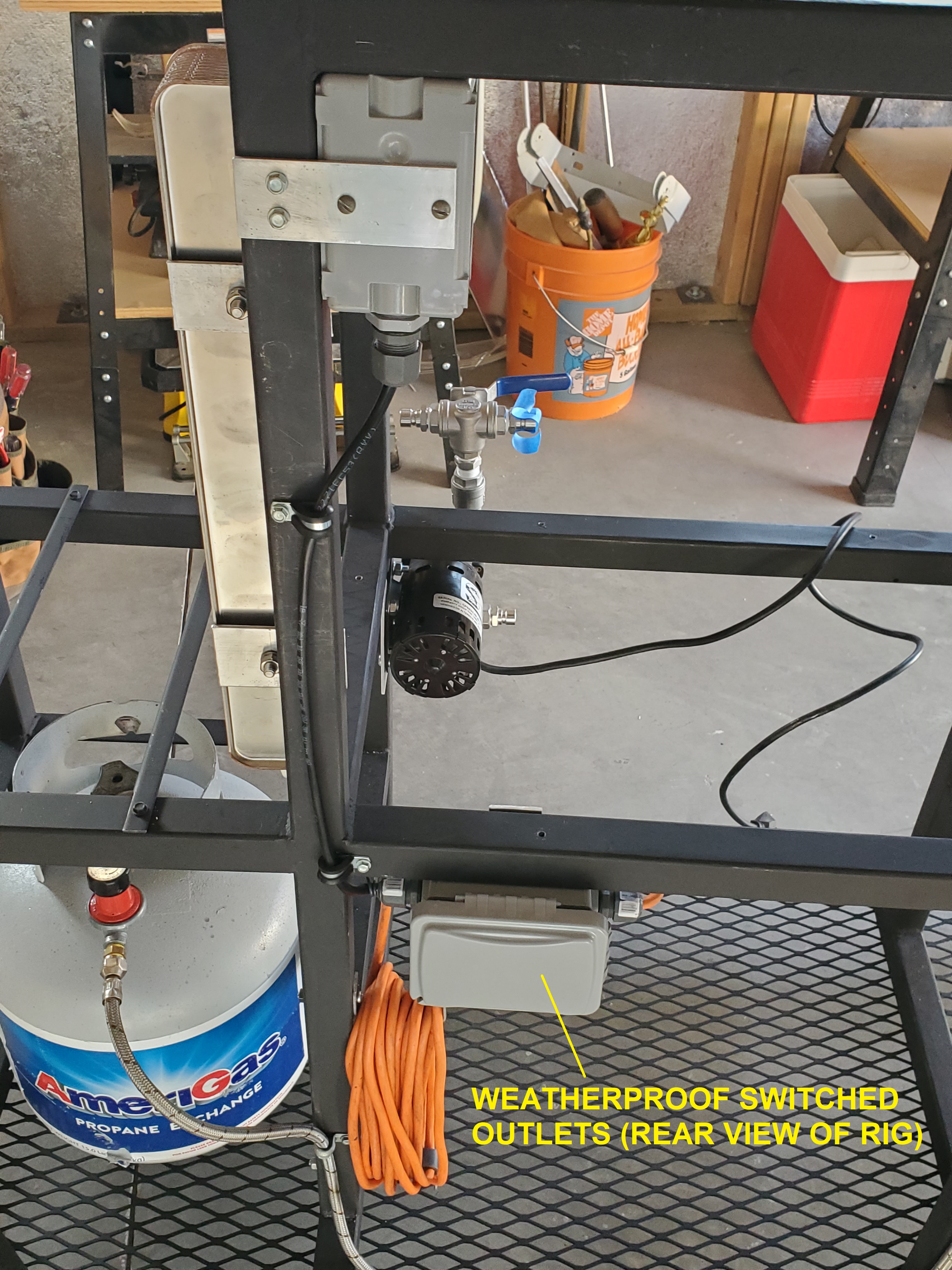

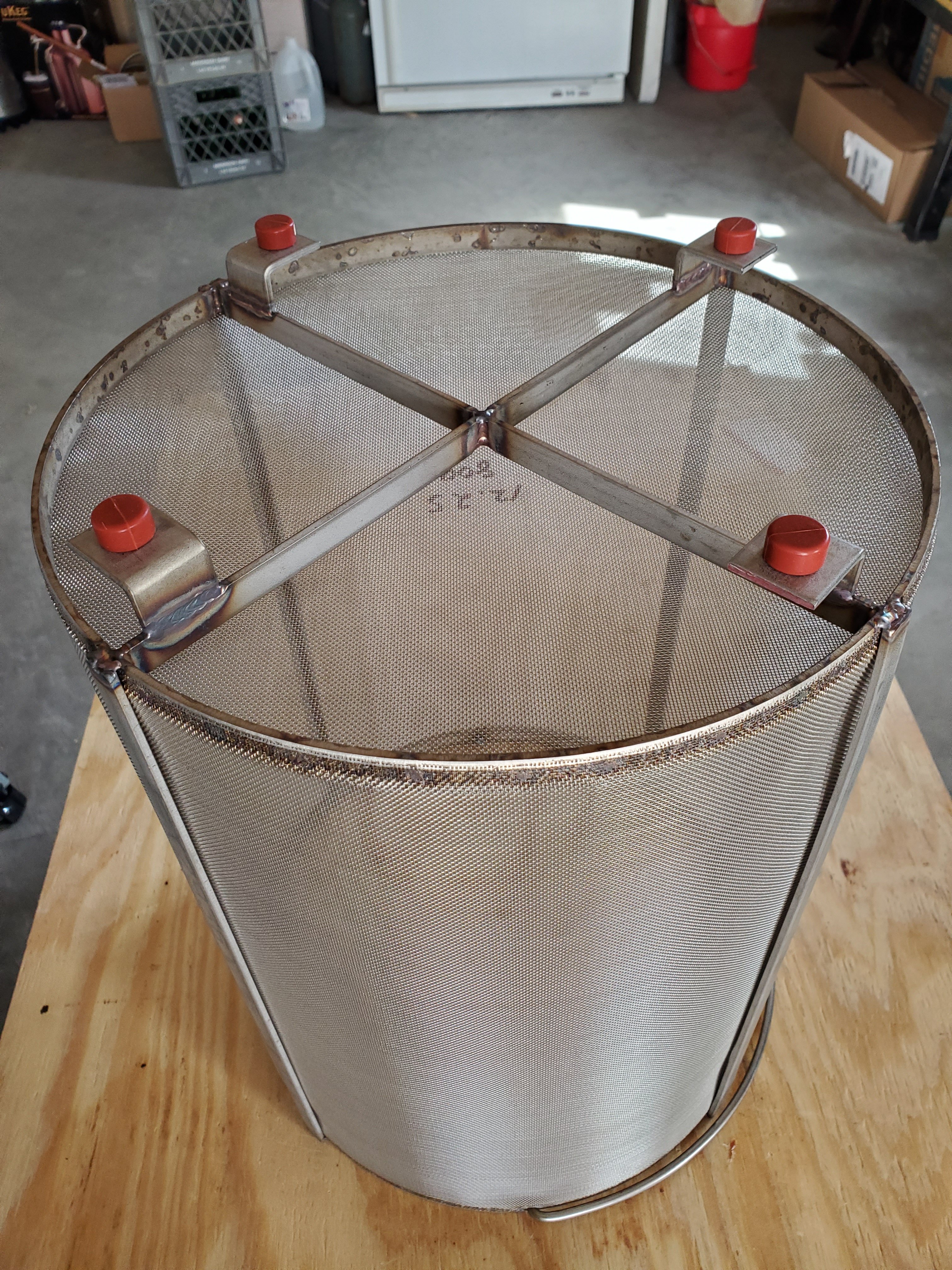

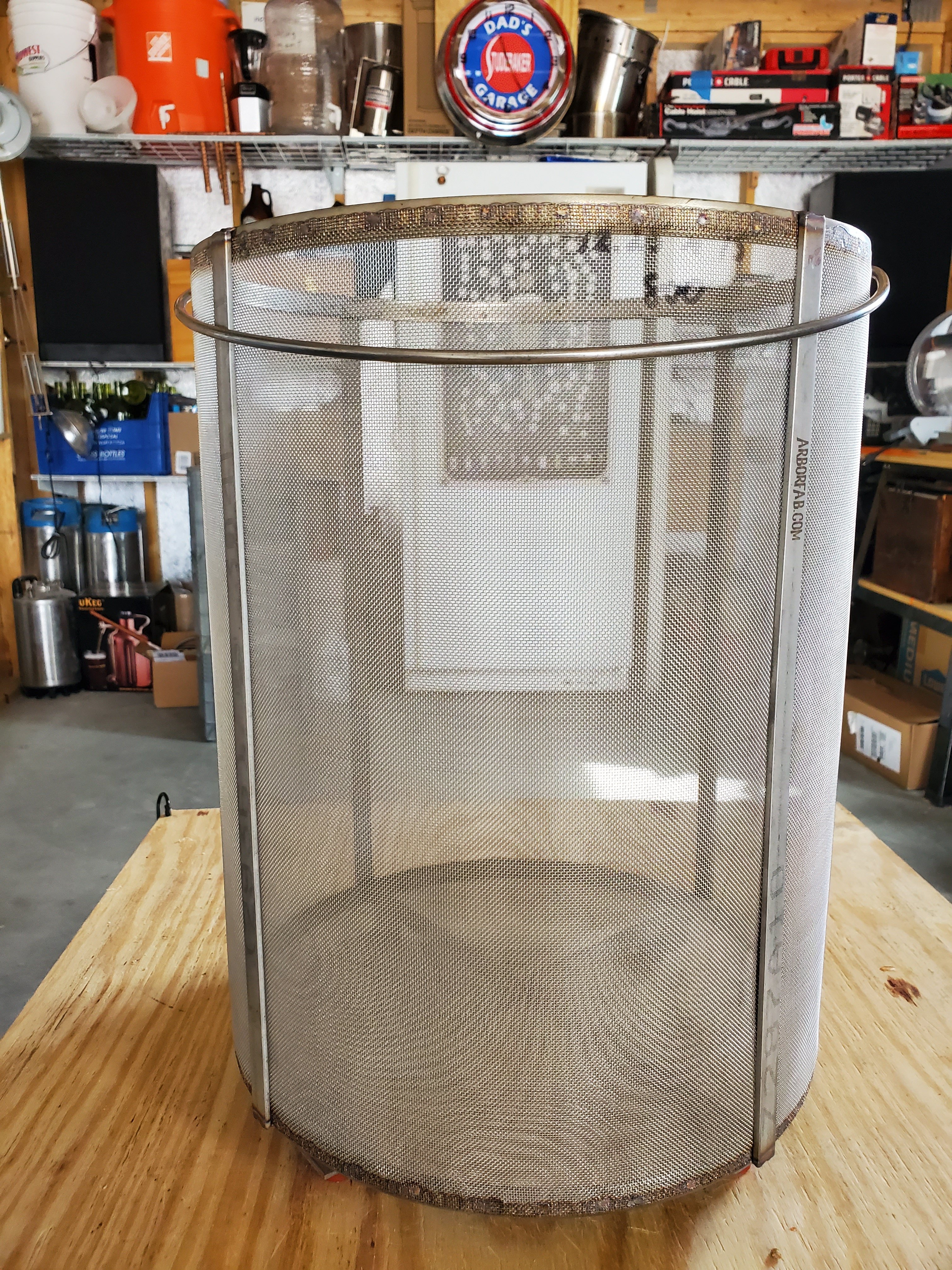

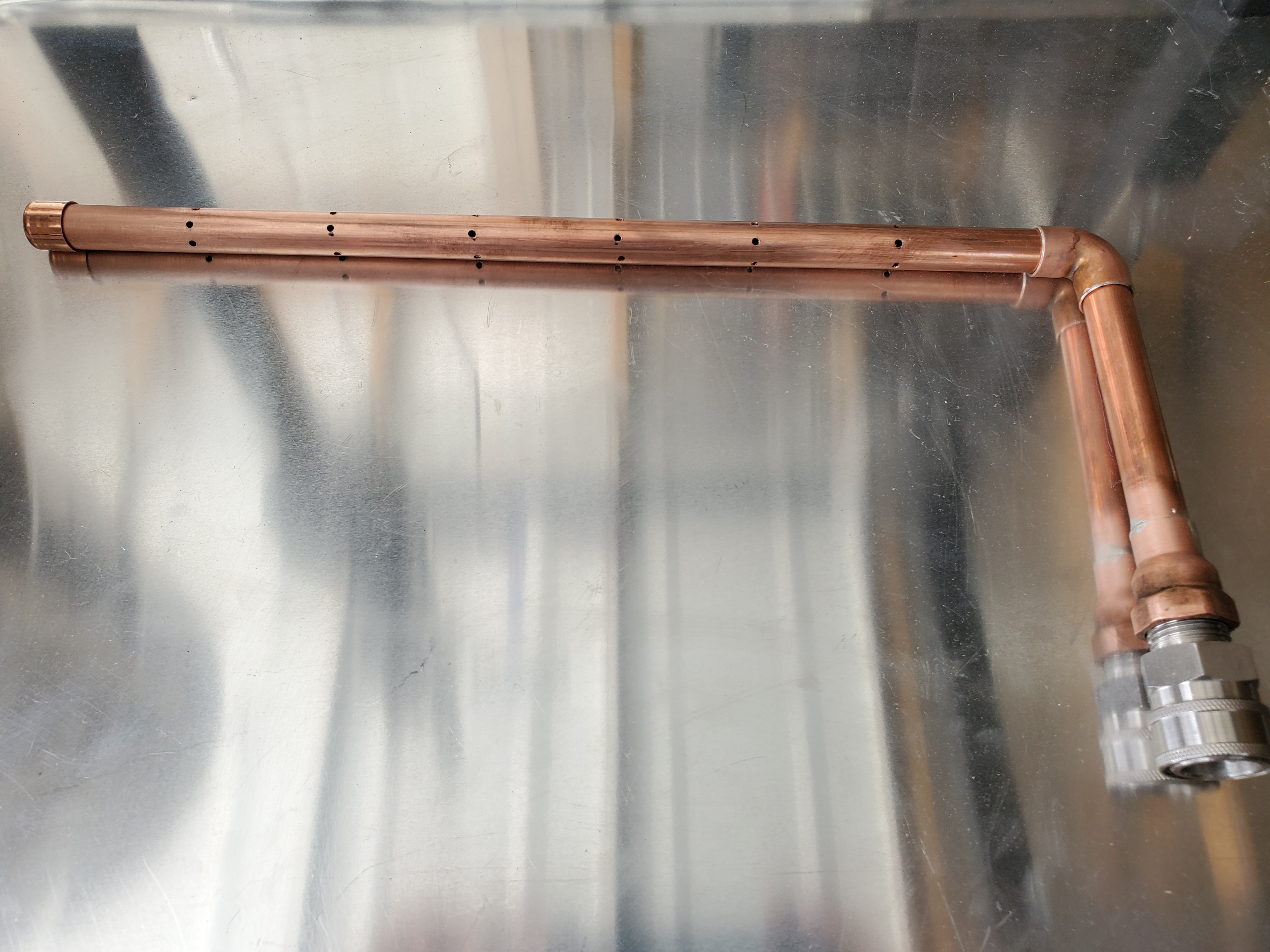

Thanks Neo, good points. I will need the burner only initially, before I get a RIMS temperature controller, to keep mash temperature constant by adding heat minimally, but I think it is prudent to have some feet on the basket, at least 1/2 inch. Since the basket bottom is flat, and the Keggle bottom is concave, the intersection is a circle.....so there is a gap (I'm approximating 1 inch) below the basket. However it is somewhat trapped in that area. I think I can give up 1/2" basket volume and still hold the 20 lbs. of grain I want for a maximum. I need to re run those volume calculations.If you fire the burner while the grain is in the basket you would certainly risk scorching. Of course, it depends on how hot you fire, etc. In my early BIAB days I did some direct firing. I found that the grain really insulated the wort from the heat. It would get very stratified very fast.

If you are planning to create a RIMS setup, you shouldn't need to fire the burner to control temp. Maybe you are thinking for temperature changes?

This isn't really my wheelhouse, but I would suggest some feet on the basket to get a little circulation below the basket. I would also suggest you figure out how to recirc around the basket if you are going to direct fire so that you can help the wort circulate better as you heat it.