EdK

Well-Known Member

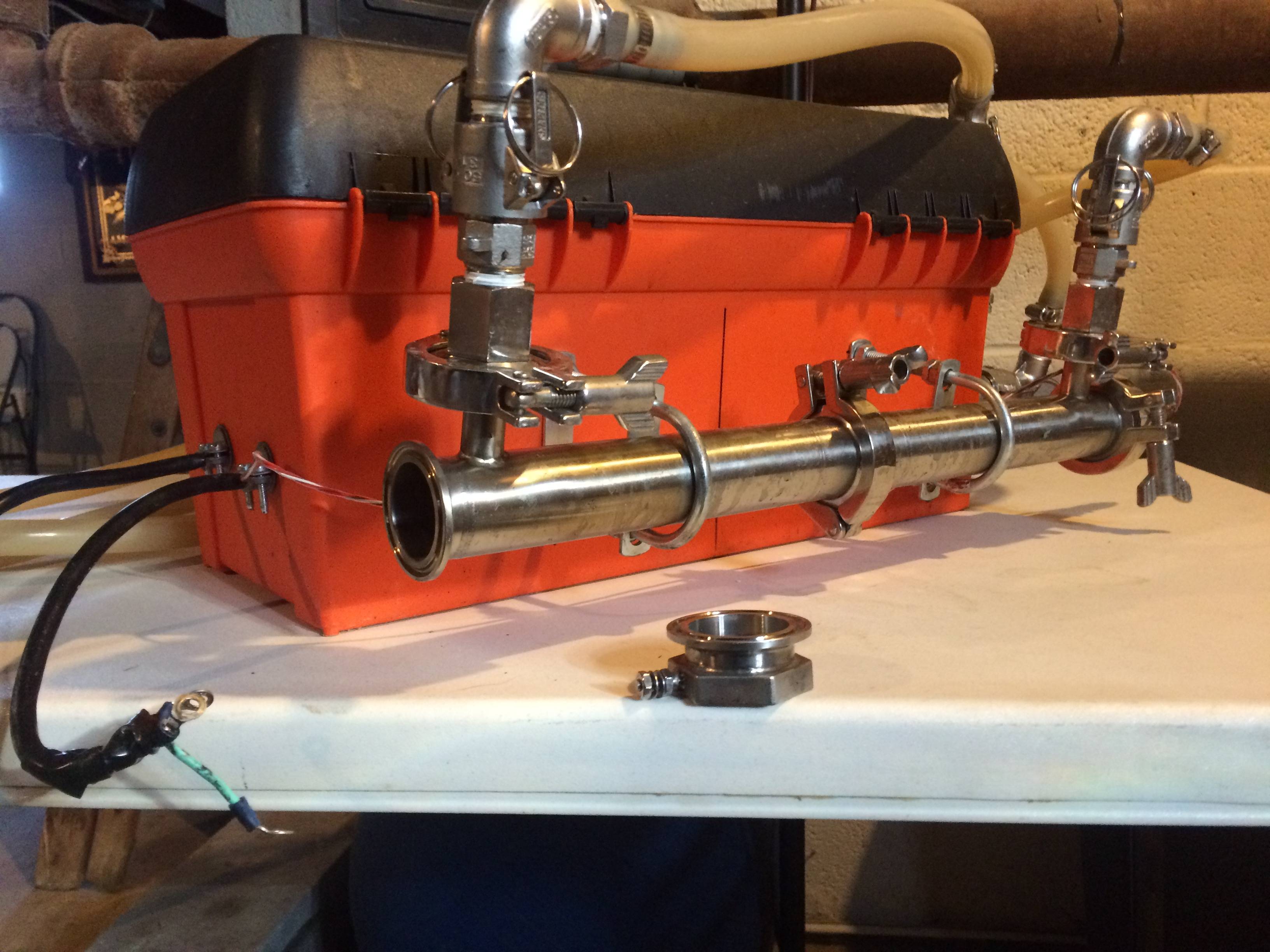

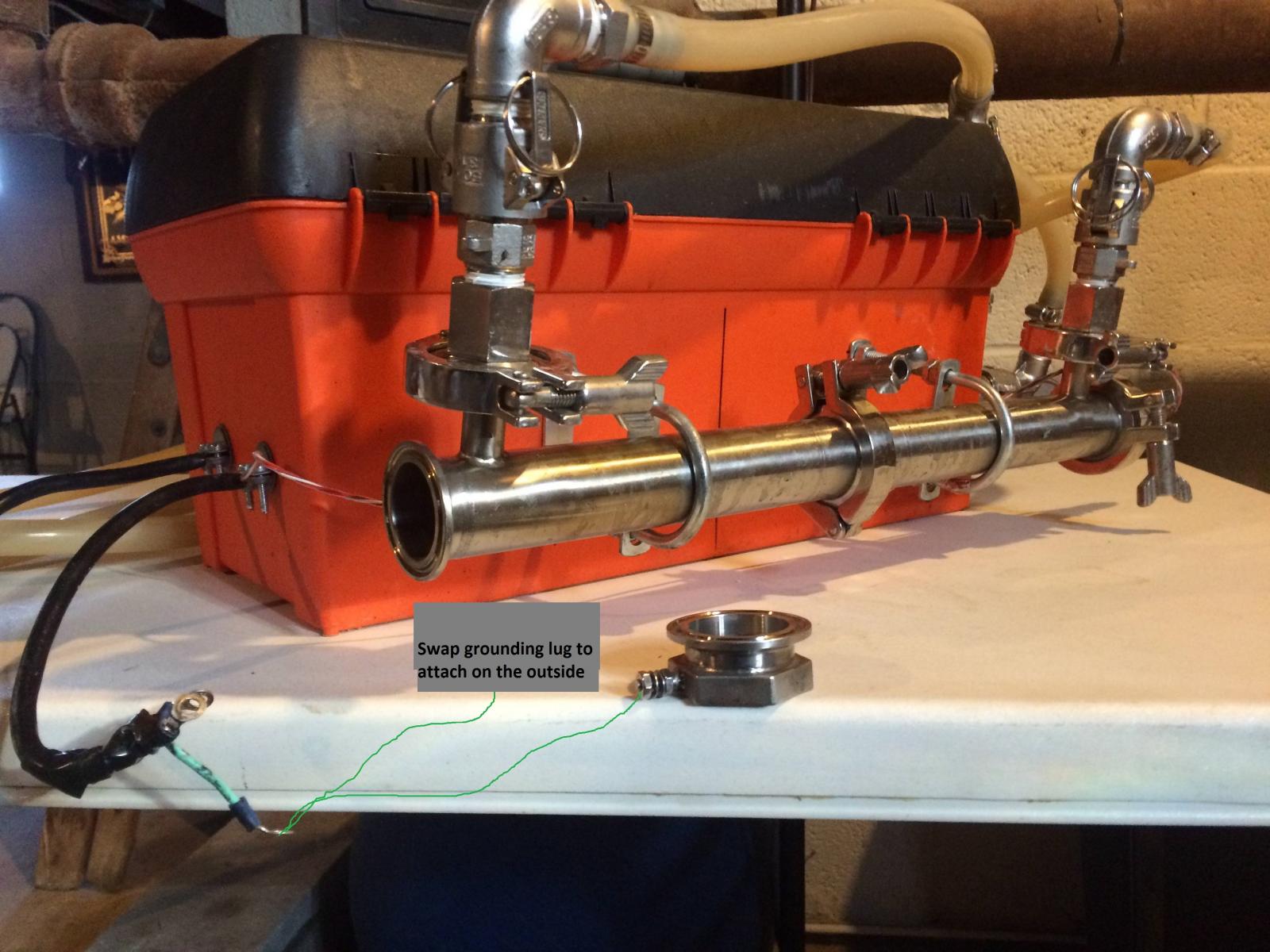

So brew day comes and my RIMS heating element fails. I turn to direct fire my MT instead but continue to use the pump and monitor temp via the probe of the RIMS tube (as well as for a whirlpool after the boil). That was a couple weeks ago and today I set out to open up the tube and and replace if needed.

What I find has me quite concerned. I pull the element out and it has basically melted and it snapped into pieces easily (see image). I do recall that the switch was flipped before any recirculating was even happening - I'm not sure how long it ran dry but as soon as I saw, I flipped it off. This is likely when it happened.

My first thought is if it is possible that this thing could have leached any toxic metals into the brew. Has anyone had this happen? I thought I read they are made of copper and covered in magnesium oxide and nickle or some such.

What I find has me quite concerned. I pull the element out and it has basically melted and it snapped into pieces easily (see image). I do recall that the switch was flipped before any recirculating was even happening - I'm not sure how long it ran dry but as soon as I saw, I flipped it off. This is likely when it happened.

My first thought is if it is possible that this thing could have leached any toxic metals into the brew. Has anyone had this happen? I thought I read they are made of copper and covered in magnesium oxide and nickle or some such.