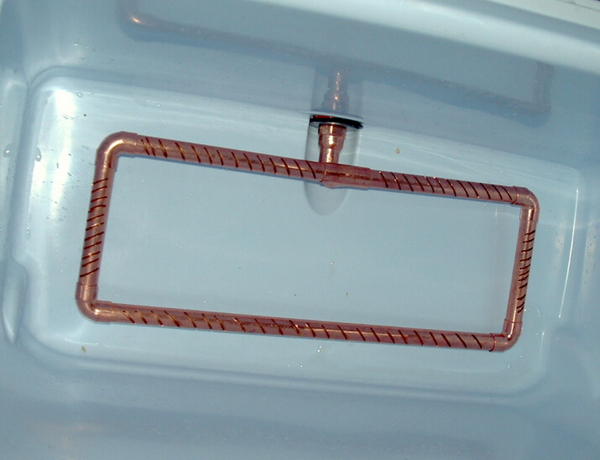

I'm building a manifold for a rectangular cooler. I'm wondering if anyone has tried drilling holes rather than cutting slits in the copper tubing. Anyone have an idea whether there would be a problem with stuck sparges or any other problems?

I don't have a very good way to cut slits in the copper.

I don't have a very good way to cut slits in the copper.