You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making Traditional rice Wine. Cheap, Fun, and Different

- Thread starter sonofgrok

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I did a batch of ARL with no additional yeast among my huge experiment, it only converted to sugar. All ARL with yeast additions fermented.

Any yeast will do? Bakers yeast? how much to add?

Depends on what you'd like your final ABV to be. Lavlin 1118 will take you to 18%. You can use 1/2 a packet on a 5 gallon fermentation since you'll lose between 25-50% to unfermentable sediment. The list of yeasts I posted earlier that I'd like to test are all higher alcohol finishing wine yeasts, several companies make sake specific yeasts. I'll have a more definitive answer once my yeast test is done around February.

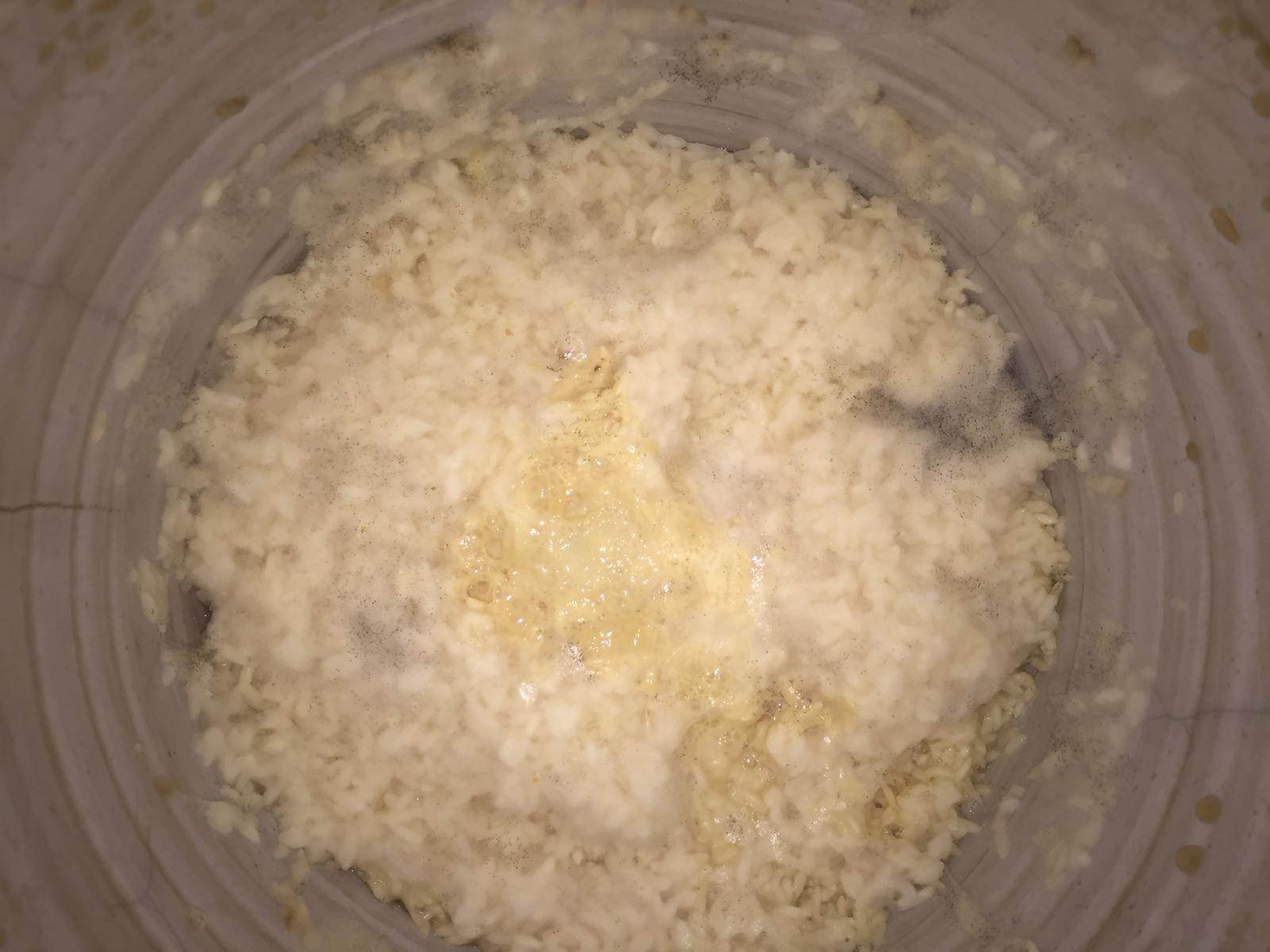

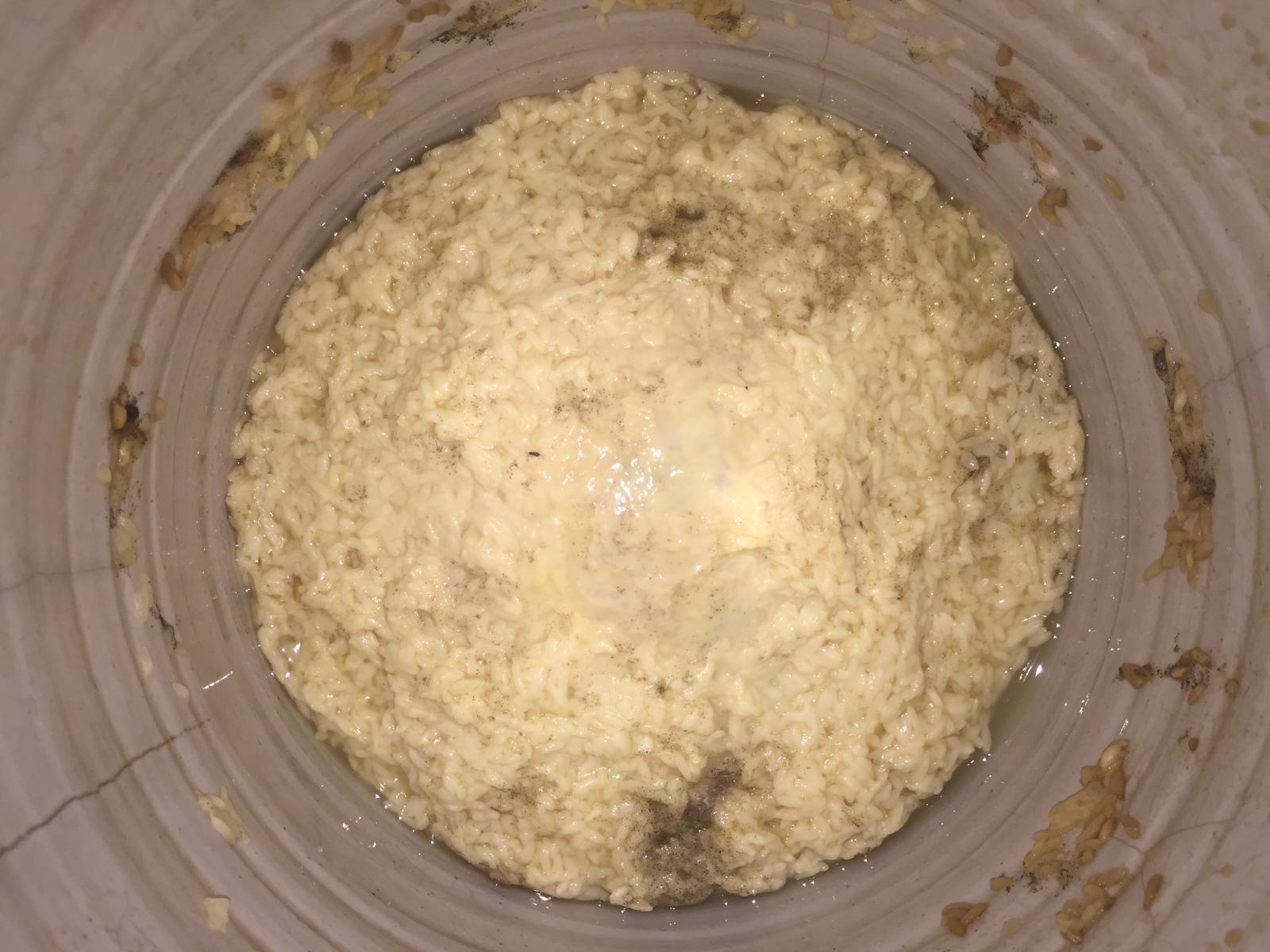

Day 7. There is a nice white mold growing on the top of the rice, in both the jars.

The smell of see through jar is slight rice, sour and slight alcohol.

There is a lot of liquid but it's not collected at the bottom.

As suggested in the previous posts that arl convert rice to sugar but not in alcohol so I added bakers yeast to both the jars.

Put 1/2 tbs yeast into 5 tbs warm water. Mixed and added 1 tbs of that to see through jar and 1.5 tbs to steamed batch.

Let's see now!

Edit: Sorry, the image is inverted ��

The smell of see through jar is slight rice, sour and slight alcohol.

There is a lot of liquid but it's not collected at the bottom.

As suggested in the previous posts that arl convert rice to sugar but not in alcohol so I added bakers yeast to both the jars.

Put 1/2 tbs yeast into 5 tbs warm water. Mixed and added 1 tbs of that to see through jar and 1.5 tbs to steamed batch.

Let's see now!

Edit: Sorry, the image is inverted ��

cuisinechemist

Member

- Joined

- Sep 3, 2016

- Messages

- 14

- Reaction score

- 0

Perhaps you are using a different ARL? Does it look like the package in Sarthak's picture? Containing Rhizopus oryzae ?I have used arl once to convert starch in rice to sugar. Cooked rice, cooled, inoculated with arl, placed in my usual jar and waited a week. It didn't produce alcohol, but a very sweet rice pudding. I'm sure if I waited it might actually spontaneously ferment. I did add bread yeast to it on the 8th day and within a few hours had active fermentation.

My point is, on the arl package, it clearly states that the package does not contain yeast. Not saying you can't make wine with it or that it won't.

The point I'm trying to make is, the package says it doesn't have yeast. If it did then it would be marketed for for making something alcoholic, not rice pudding.

I've used that one and my family has been using it for years. I believe it is marketed to make fermented jiuniang, which is what my family uses it for- that could be considered rice pudding, but it is alcoholic rice pudding. The package says "ready to eat when wine aroma appears". In about a few days you will get a very slightly alcoholic product- or you are supposed to. I'm on here because I want to learn about making it into alcohol for drinking and not as fermented rice

I'm not a biologist, but is Rhizopus oryzae not a fungus that is capable of alcohol fermentation? Had a quick read through the scientific literature and they seem to suggest that it has the amylases to break down the starches and then metabolizes the sugar into CO2 and ethanol

cuisinechemist

Member

- Joined

- Sep 3, 2016

- Messages

- 14

- Reaction score

- 0

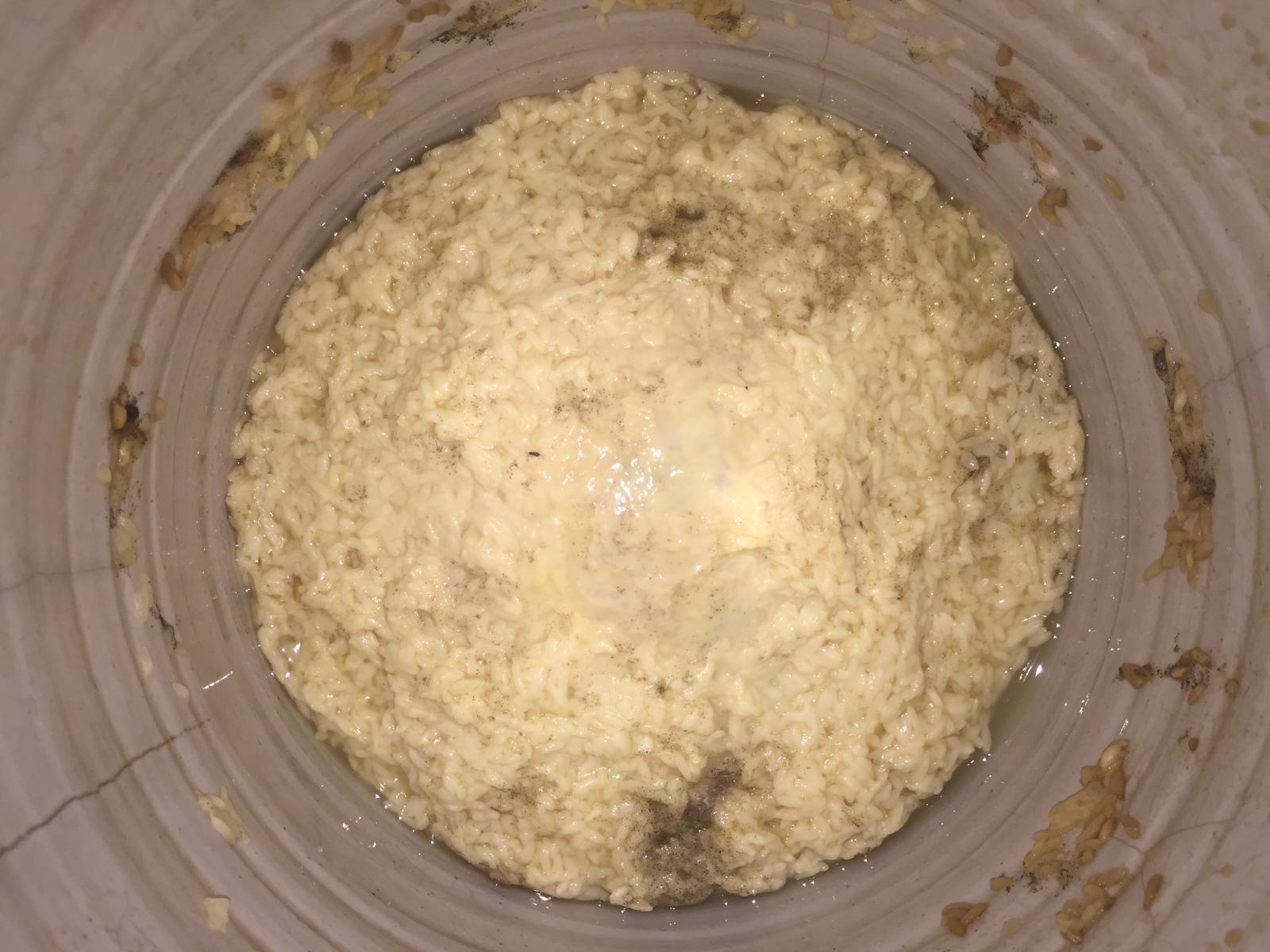

I just made a new batch on Wednesday. I was worried a little as I didn't hear much bubbling going on like I did ring my earlier batches, perhaps it is the cooler tenperatures but I took a quick peak inside and it is fermenting away! Still amazes me how there are so many living things in there.

I am almost out of my sweet rice. The next step I guess is to try Jasmine!

I am almost out of my sweet rice. The next step I guess is to try Jasmine!

Darthbrewder

Well-Known Member

Cuisinechemist, I didn't see any pictures of a package of arl posted by sarthak. But I did post a picture of a package.

Rhizopus oryzae is a fungus that can liquefy and break down starch into sugar at or slightly above room temperature. It is not yeast and cannot ferment the sugars that it produces on its own.

Much like aspergillus oryzae, also known as koji, the fungus is used to break down the starch in rice. Then, usually, a strain of sake yeast is incorporated to start the fermentation process.

While the two are not exactly the same, one could argue that the two fungi could be used interchangeably to produce sake.

Rhizopus oryzae is a fungus that can liquefy and break down starch into sugar at or slightly above room temperature. It is not yeast and cannot ferment the sugars that it produces on its own.

Much like aspergillus oryzae, also known as koji, the fungus is used to break down the starch in rice. Then, usually, a strain of sake yeast is incorporated to start the fermentation process.

While the two are not exactly the same, one could argue that the two fungi could be used interchangeably to produce sake.

cuisinechemist

Member

- Joined

- Sep 3, 2016

- Messages

- 14

- Reaction score

- 0

Cuisinechemist, I didn't see any pictures of a package of arl posted by sarthak. But I did post a picture of a package.

Rhizopus oryzae is a fungus that can liquefy and break down starch into sugar at or slightly above room temperature. It is not yeast and cannot ferment the sugars that it produces on its own.

Much like aspergillus oryzae, also known as koji, the fungus is used to break down the starch in rice. Then, usually, a strain of sake yeast is incorporated to start the fermentation process.

While the two are not exactly the same, one could argue that the two fungi could be used interchangeably to produce sake.

I know that yeast is added when making sake (My knowledge of the entire process of sake making is limited though) and often the rice wine we are making in this thread as well.

However, from what I am reading, the Rhizopus oryzae and Aspergillus oryzae can metabolize alcohol into sugar too.

From the textbook "Objective Botany" "Rhizopus oryzae brings about alcohol fermentation. Answer: True"

From a thesis on sugar metabolism in R oryzae "Rhizopus oryzae is a filamentous fungus, which can produce high amounts of L(+)- lactic acid and produces ethanol as the main by-product." (which agrees with many articles I have read)

What I'm thinking is that adding yeast will increase alcohol production, but even without it, you'll still get alcohol. I think yeast mostly ferments sugar into CO2 and ethanol. Whereas the R oryzae it seems, mostly produces lactic acid during aerobic respiration, with ethanol as a main byproduct. (Correct me if I am wrong, biologists

I recall reading here people experimenting with different ratios of yeast and ARL and seeing how it affected the end result/ flavour.

cuisinechemist, your thinking seems correct and spurred a little research on my end.

After reading over half of the pages in this thread, I have have some ideas as to why the addition of yeast improves ethanol production, why an open fermentation (with no airlock) seems to work well for rice wine production, and why a fermentation with an airlock also works well. I'll present my ideas first and the rationale second because the microbiology will bore some folks to death.

Thoughts about rice wine fermentations - Based on my biology background and skimming research papers, I think that:

1. Use of an airlock vs an open fermentation may affect metabolites produced. I suspect that an airlock results in a fermentation with a "cleaner" flavor profile and a lesser chance of contamination from bacteria.

2. Ferment on the colder side will reduce production of lactic acid and other undesirable "off-flavor" compounds (potentially acetate as well), and will reduce the chance of bacterial contamination.

3. Make certain that both yeast and fungi are present in the fermentation. There is no harm in adding supplemental yeast, especially yeasts with high alcohol tolerance.

That said, I will be trying side-by-side batches of rice wine with and without airlocks to see if there is a difference in the final product!

Microbiolgical background - In case you care about the reasoning for my ideas:

1. Filamentous fungi can produce a rice wine on their own without yeast. Some, if not all fungi used for rice wine can produce ethanol under both aerobic and anerobic conditions, but have a limited or lesser tolerance for ethanol than yeast, especially at higher temperatures (a).

2. Rice wine cannot be produced without fungi because yeast lack the enzymes to break down complex carbohydrates and starches into fermentable mono and disaccharides.

3. The addition of yeast and fungi improves the conversion of carbohydrates to ethanol, resulting in a higher ABV. (a)

4. An open fermentation without an airlock allows for production of ethanol through both aerobic (fungi) and anaerobic (fungi and yeast) pathways. However, the risk of lactic acid production from fungi and/or contaminating bacteria is higher as production of lactic acid is more energetically favorable through an aerobic pathway (b). Lactic acid production is also greater with increasing fermentation temperature (d).

5. The acetone or "solvent" flavors sometimes observed in a young rice wine will clear up over time. Fungi can produce acetate during a fermentation but it is consumed once glucose is depleted (c). Production of acetate is greater with increasing fermentation temperature (d).

I must add the caveat that I made some rather broad generalizations about fungal metabolism and didn't specifically look up the strains common to rice wine fermentation.

References -

(a): http://bmcbiotechnol.biomedcentral.com/articles/10.1186/s12896-015-0130-3

(b) https://en.wikipedia.org/wiki/Anaerobic_organism

(c) https://www.hindawi.com/journals/ijmicro/2009/571383/

(d) https://www.hindawi.com/journals/bmri/2014/426929/ <- this paper is a goldmine of information on optimization of yeast growth and ethanol production in rice wine!

After reading over half of the pages in this thread, I have have some ideas as to why the addition of yeast improves ethanol production, why an open fermentation (with no airlock) seems to work well for rice wine production, and why a fermentation with an airlock also works well. I'll present my ideas first and the rationale second because the microbiology will bore some folks to death.

Thoughts about rice wine fermentations - Based on my biology background and skimming research papers, I think that:

1. Use of an airlock vs an open fermentation may affect metabolites produced. I suspect that an airlock results in a fermentation with a "cleaner" flavor profile and a lesser chance of contamination from bacteria.

2. Ferment on the colder side will reduce production of lactic acid and other undesirable "off-flavor" compounds (potentially acetate as well), and will reduce the chance of bacterial contamination.

3. Make certain that both yeast and fungi are present in the fermentation. There is no harm in adding supplemental yeast, especially yeasts with high alcohol tolerance.

That said, I will be trying side-by-side batches of rice wine with and without airlocks to see if there is a difference in the final product!

Microbiolgical background - In case you care about the reasoning for my ideas:

1. Filamentous fungi can produce a rice wine on their own without yeast. Some, if not all fungi used for rice wine can produce ethanol under both aerobic and anerobic conditions, but have a limited or lesser tolerance for ethanol than yeast, especially at higher temperatures (a).

2. Rice wine cannot be produced without fungi because yeast lack the enzymes to break down complex carbohydrates and starches into fermentable mono and disaccharides.

3. The addition of yeast and fungi improves the conversion of carbohydrates to ethanol, resulting in a higher ABV. (a)

4. An open fermentation without an airlock allows for production of ethanol through both aerobic (fungi) and anaerobic (fungi and yeast) pathways. However, the risk of lactic acid production from fungi and/or contaminating bacteria is higher as production of lactic acid is more energetically favorable through an aerobic pathway (b). Lactic acid production is also greater with increasing fermentation temperature (d).

5. The acetone or "solvent" flavors sometimes observed in a young rice wine will clear up over time. Fungi can produce acetate during a fermentation but it is consumed once glucose is depleted (c). Production of acetate is greater with increasing fermentation temperature (d).

I must add the caveat that I made some rather broad generalizations about fungal metabolism and didn't specifically look up the strains common to rice wine fermentation.

References -

(a): http://bmcbiotechnol.biomedcentral.com/articles/10.1186/s12896-015-0130-3

(b) https://en.wikipedia.org/wiki/Anaerobic_organism

(c) https://www.hindawi.com/journals/ijmicro/2009/571383/

(d) https://www.hindawi.com/journals/bmri/2014/426929/ <- this paper is a goldmine of information on optimization of yeast growth and ethanol production in rice wine!

So the last reference in my post above contains some really great information about optimal fermentation temperatures to maximize ethanol production and minimize the production of volatile organic acids, primarily lactic and acetic acid. In summary:

1. Start fermentations at room temperature (23C/74F) to maximize yeast cell growth

2. Reduce temperatures (18C/64F) once fermentation is about 1/2 complete to minimize the effects of ethanol toxicity on yeast and obtain a higher final ABV

3. Cooler temperatures reduce production of volatile acids from both yeast and most importantly, from Lactobacillus which is the primary producer of lactic acid a high temperatures.

4. volatile acids produced result in "flavors" in the rice wine. A moderate level of these compounds is desirable but an excess (i.e., high temperature fermentation) will make the rice wine unpalatable.

Effect of Temperature on Chinese Rice Wine Brewing with High Concentration Presteamed Whole Sticky Rice

1. Start fermentations at room temperature (23C/74F) to maximize yeast cell growth

2. Reduce temperatures (18C/64F) once fermentation is about 1/2 complete to minimize the effects of ethanol toxicity on yeast and obtain a higher final ABV

3. Cooler temperatures reduce production of volatile acids from both yeast and most importantly, from Lactobacillus which is the primary producer of lactic acid a high temperatures.

4. volatile acids produced result in "flavors" in the rice wine. A moderate level of these compounds is desirable but an excess (i.e., high temperature fermentation) will make the rice wine unpalatable.

Effect of Temperature on Chinese Rice Wine Brewing with High Concentration Presteamed Whole Sticky Rice

Darthbrewder

Well-Known Member

Well I guess I was mistaken. I just got finished reading a lot of articles and research papers that are well over my head. In closing some that were shared in this thread. I never thought to research whether or not the fungus rhizopus oryzae was capable of producing ethanol. I just figured since it didn't produce any for the small experiments that I performed, that it wasn't able to do so, without the addition of some form of yeast.

Thanks for all the research and info on this. This thread is still interesting even after all this time.

My apologies for misinforming anyone on this matter. I was certain that I was right [emoji28].

That said I have 2.5 pounds of glutinous Thai rice waiting for inoculation. Cheers!

Thanks for all the research and info on this. This thread is still interesting even after all this time.

My apologies for misinforming anyone on this matter. I was certain that I was right [emoji28].

That said I have 2.5 pounds of glutinous Thai rice waiting for inoculation. Cheers!

I think everyone in this thread who provides their experiences or opinions (right, wrong, correct or incorrect or anywhere in between) is doing so with good intentions. That's what makes this site great. We are all hoping to make something we can drink, enjoy and be proud of.

Optimum process using Aspergillus Oryzae (koji)

1. Cook rice 1:1.1 ratio dry rice:water (or steam).

2. Cool rice to 95F.

3. Inoculate with spores and 2 tbs lemon juice per 5 gallon batch.

Koji converts starch to sugar at 95F in optimum amounts. Below this temperature you get more proteins produced by the mold.

4. Stir the koji rice at 95F every 12 hours until no whole grains remain. A. oryzae needs o2 to work.

5. Transfer to airlocked container with added aggressive yeast.

6.Wait until bubbles slow to 10 secs per bubble, break up cap and stir.

7. Wait till energized yeast slows to 10 secs again.

8. Strain, bottle.

55-65F for fermentation temp reduces possibility of sourness.

I just finished a 6.5 gallon batch that my friend back from Japan said was, "unquestionably good, even compared with professional sake."

1. Cook rice 1:1.1 ratio dry rice:water (or steam).

2. Cool rice to 95F.

3. Inoculate with spores and 2 tbs lemon juice per 5 gallon batch.

Koji converts starch to sugar at 95F in optimum amounts. Below this temperature you get more proteins produced by the mold.

4. Stir the koji rice at 95F every 12 hours until no whole grains remain. A. oryzae needs o2 to work.

5. Transfer to airlocked container with added aggressive yeast.

6.Wait until bubbles slow to 10 secs per bubble, break up cap and stir.

7. Wait till energized yeast slows to 10 secs again.

8. Strain, bottle.

55-65F for fermentation temp reduces possibility of sourness.

I just finished a 6.5 gallon batch that my friend back from Japan said was, "unquestionably good, even compared with professional sake."

cuisinechemist

Member

- Joined

- Sep 3, 2016

- Messages

- 14

- Reaction score

- 0

AgreedI think everyone in this thread who provides their experiences or opinions (right, wrong, correct or incorrect or anywhere in between) is doing so with good intentions. That's what makes this site great. We are all hoping to make something we can drink, enjoy and be proud of.

After all, it appears that adding yeast certainly does have benefits. I'm a little nervous about using my baker's yeast because I never have good luck with it, but maybe once I get my hands on some wine yeast...

I know! I am still reading through all the posts and not tired yet. Never expected to learn so much science... and never thought I would be reading microbiology papers. I do love a good scientific paper, but microbiology is often way over my head.This thread is still interesting even after all this time.

And thanks ten80 for the research and explanations. (Still going through those references with great interest

And I will try your temperature recommendations. I've been wrapping my batch in lots of blankets because it's freezing here, but now it seems that the fermentation is well underway so I might remove the blankets.

Once I buy more rice I will actually try some experiments to test the different factors out!

Adding simple bakers yeast has taken the fermentation to a different level. I added yeast 2 days back. The smell of the two batches was average, very Ricey, tart. Now they smell a lot of alcohol. There is a lot of liquid in the steamed batch too! Which was not present before.

But it amazes me, all those people who are avid brewers and have made rice wine with just ARL and rice, how? The batches had alcohol aroma before adding the yeast but it was not so prominent.

Also, if arl just convert the starch in rice to more sugar and less alcohol, then when is adding the yeast most appropriate? I think adding it on 14th day mark would be best because a lot of starch to sugar conversion would be done by then.

The wine yeast available at eBay here are these( see the picture attached). Now these are costly yeasts, when I buy these I wouldn't want to waste any on experimentation.

But it amazes me, all those people who are avid brewers and have made rice wine with just ARL and rice, how? The batches had alcohol aroma before adding the yeast but it was not so prominent.

Also, if arl just convert the starch in rice to more sugar and less alcohol, then when is adding the yeast most appropriate? I think adding it on 14th day mark would be best because a lot of starch to sugar conversion would be done by then.

The wine yeast available at eBay here are these( see the picture attached). Now these are costly yeasts, when I buy these I wouldn't want to waste any on experimentation.

The Cotes des Blancs is probably the best flavor, the 1118 will get you the most alcohol. Each pack makes enough for 5 gallons of liquid (so around 8 gallons of rice). These ebay listings are for 10 packs. In other words, one of these purchases will make you 320 dry lbs of rice worth of rice wine.

The Cotes des Blancs is probably the best flavor, the 1118 will get you the most alcohol. Each pack makes enough for 5 gallons of liquid (so around 8 gallons of rice). These ebay listings are for 10 packs. In other words, one of these purchases will make you 320 dry lbs of rice worth of rice wine.

So yeast is definitely required along with arl? And when to add, at beginning or at 14 day mark.

So yeast is definitely required along with arl? And when to add, at beginning or at 14 day mark.

In a sterile environment, probably. You should be using your preferred yeast anyhow, rice wine is flavored by 5 things: rice, water, yeast, mold, PH modifier.

Most homebrewers aren't going to be able to change their water supply, ARL brewers have mold set (Rhizopus Oryzae).

That leaves rice, yeast, and ph modifier. You can add acid or bacteria to lower ph our molds prefer 5.5-6. Cooked rice is 6.3-6.5.

Since bacteria is alive, it can skew results. This is why I choose to use lemon juice or some other acid.

Now what's left is rice and yeast. Most people on this thread are making the wine because it's decent and cheap. It follows that the cheapest passable rice is the best for our purposes. Costco members have access to .563 per lb jasmine rice. People near asian grocers can find decent "sushi rice" for .567 per lb.

This leaves yeast. Find a yeast you like the flavor of (I'll be testing around 10 in January and posting results) and use it to outcompete less productive/efficient wild yeasts.

So I understand that the ARL does not contain yeast. How about the rice yeast balls? I picked up a bag of "yeast" balls labeled "rice cake" from the local Asian grocery store. There is no mention of yeast on the package.

I checked on both the wine batches; the smell difference in boiled rice vs the steamed rice is like night and day. The cooked rice has a weak, slight alcohol, slight tang, slight rice smell. The liquid is very slight blue, cloudy in colour. On the other hand, steamed rice has very very pungent smell, it hits you in the face. The colour is ember and it is still bubbling.

Is there any difference in end product of steaming and cooking the rice? I'll put the steamed rice batch in a glass jar next time.

Is there any difference in end product of steaming and cooking the rice? I'll put the steamed rice batch in a glass jar next time.

So, I want to attempt to try this out for fun. I've read the first couple pages and some stuff from other sites, but I want to know does the rice wine needs to be kept in the refrigerator after the fermentation? What happens if it doesn't? Is there a way to allow it to age?

@sarthak: Boiled rice tends to have more liquid. More liquid in this brew makes more wine and more vinegar flavor.

@alien: If you like the flavor of the wine, pasteurize it. This will prevent further aging and make it shelf stable. Most people store in fridge after straining because it slows down fermentation, causes particulate to settle, and most people drink it faster than any difference pasteurization would make.

@alien: If you like the flavor of the wine, pasteurize it. This will prevent further aging and make it shelf stable. Most people store in fridge after straining because it slows down fermentation, causes particulate to settle, and most people drink it faster than any difference pasteurization would make.

I see, thank you. Also I want to ask if anyone knows of a technique of where you steam rice along with yeast ball to ferment into droplet of rice wine?

I was told, after I said I was going to attempt this, that my grandpa use to make rice wine by steaming the rice with the yeast ball. He would somehow extract the alcohol during that process. I can't exactly ask him anymore so now it's kind of a lost technique.

I'm not exactly if that is what he did or how it works.

I was told, after I said I was going to attempt this, that my grandpa use to make rice wine by steaming the rice with the yeast ball. He would somehow extract the alcohol during that process. I can't exactly ask him anymore so now it's kind of a lost technique.

I'm not exactly if that is what he did or how it works.

I see, thank you. Also I want to ask if anyone knows of a technique of where you steam rice along with yeast ball to ferment into droplet of rice wine?

I was told, after I said I was going to attempt this, that my grandpa use to make rice wine by steaming the rice with the yeast ball. He would somehow extract the alcohol during that process. I can't exactly ask him anymore so now it's kind of a lost technique.

I'm not exactly if that is what he did or how it works.

Are you asking about getting the wine out while it is still being fermented?

A simple method to do that is put a cheesecloth(any cloth with a lot a mesh of gaps in it) on the bottom of your fermenting jar. Then put your rice with yeast added onto the cloth. So that way, the wine produced will just strain out of the cloth leaving behind the rice which you can pull along with the cloth.

Like I'm this video: https://youtu.be/XrBTS7Ija1w

Do not add yeast to rice while steaming it or when the rice is still hot because that will kill the yeast.

Maybe they're talking about distilling. From my own tests, if you keep the rice at a constant 100F with the mold and proper ph above a filtration system, liquid glucose will collect at the bottom of the container. You can use that w/ yeast to ferment 100% liquid rather than the solid rice fermentation that makes up the bulk of this thread.

I think chonas is right. It's pretty much that. From what I learn he would have a setup where he would have water at the bottom and the rice with the yeast ball mixed in and steam/ferment at a temperature. The liquor would be extracted while it's steaming. If it's distilling and that is how it works I think that is what he probably did.

Yeast can be steamed at the right temperature. From what I know, yeast can produce an enzyme called 'catalase'. Since enzyme best temperature reaction temperature is at 97F or 32C, it makes sense that if it's steamed at low temperature it can ferment at a much faster rate. Any temperature too low (would make it less active) or high can denature these enzyme. The enzyme can be denature by too much acidity too. As a product of the enzyme, it breaks down sugar and release co2 and ethyl alcohol.

Thank you chonas. I think I'll look into how to distill. Or if possible point me to a guide about it.

Thanks again.

Yeast can be steamed at the right temperature. From what I know, yeast can produce an enzyme called 'catalase'. Since enzyme best temperature reaction temperature is at 97F or 32C, it makes sense that if it's steamed at low temperature it can ferment at a much faster rate. Any temperature too low (would make it less active) or high can denature these enzyme. The enzyme can be denature by too much acidity too. As a product of the enzyme, it breaks down sugar and release co2 and ethyl alcohol.

Thank you chonas. I think I'll look into how to distill. Or if possible point me to a guide about it.

Thanks again.

Maybe they're talking about distilling. From my own tests, if you keep the rice at a constant 100F with the mold and proper ph above a filtration system, liquid glucose will collect at the bottom of the container. You can use that w/ yeast to ferment 100% liquid rather than the solid rice fermentation that makes up the bulk of this thread.

So what that means is that after mixing in the rice and the mold and keeping it in a container to ferment; if the temperature of the container is maintained at say 100F, the wine production would be maximum?

I read somewhere earlier in this thread(maybe between page 270-290) that this mold that we use produce more esters or sweetness between temperature of 32C to 36C and it produces more acids between 36C to 40C.

So what that means is that after mixing in the rice and the mold and keeping it in a container to ferment; if the temperature of the container is maintained at say 100F, the wine production would be maximum?

I read somewhere earlier in this thread(maybe between page 270-290) that this mold that we use produce more esters or sweetness between temperature of 32C to 36C and it produces more acids between 36C to 40C.

The bacteria included in yeast balls produces sourness. Koji's optimum amylase production of sugars is at 95F http://www.taylor-madeak.org/making-koji-1/making-koji-2/ . Below 90F the mold produces more protein (people that make charcuterie use it for this purpose, also tempeh).

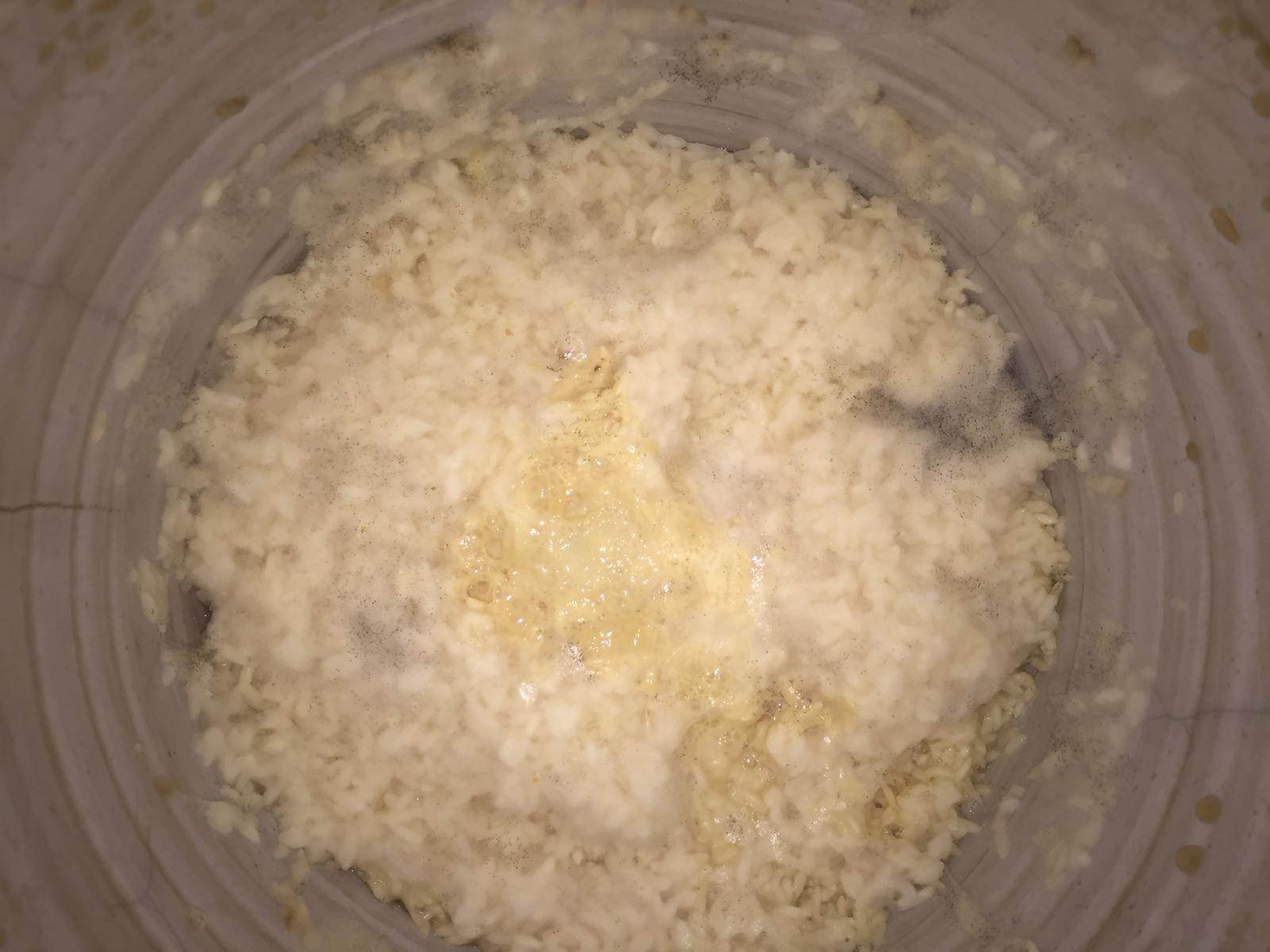

I came up with an automation idea (if I had the money) image included. That would require heat, a conical, and a filter.

Knowns: Koji needs oxygen to produce glucose. Koji's optimum glucose from amylopectin temperature is 95F.

In the image, you figure out how long the collection vessel takes to fill, add new rice and stir the koji at that time while collecting glucose. This oxygenates and renews glucose supply.

Move the glucose to secondary fermentation with your choice of yeast. This keeps oxygen out of the fermentation (reducing sourness), and allows the 2 steps of the fermentation to occur at their optimum temperatures. Plus yeast is happier in liquid than on solid rice.

cuisinechemist

Member

- Joined

- Sep 3, 2016

- Messages

- 14

- Reaction score

- 0

Just tried some of wine that has been fermenting for ~10 days. I tried it on day 5 and it was sweet and had slight alcohol, but now it is *not sweet* at all and quite strong, but the rice looks too solid for it to be done. It's not sour either, just tastes mostly like alcohol, with some rice aroma. It burns my nose and throat too. Really not sure what happened

I followed the same procedure as I always have. Sweet rice in rice cooker, let cool, add ARL + sugar.

Any thoughts/ solutions?

I like my wine sweet but I don't feel like I got enough liquid yet.

Should I pasteurize and sweeten with simple syrup? Add more cooked rice??

I followed the same procedure as I always have. Sweet rice in rice cooker, let cool, add ARL + sugar.

Any thoughts/ solutions?

I like my wine sweet but I don't feel like I got enough liquid yet.

Should I pasteurize and sweeten with simple syrup? Add more cooked rice??

cuisinechemist

Member

- Joined

- Sep 3, 2016

- Messages

- 14

- Reaction score

- 0

That makes sense! It does remind me a bit of rum...Oh sweetie. No sugar addition necessary in this brew. You only need the cooked rice and fermentation critters. You ve made a precursor to rum with rice flavoring.

I usually add sugar, but it's totally possible that I added a tad too much

In previous batches it is still super sweet and low alcohol by day 20. I know because I don't drink much and don't have a lot of tolerance, but I can drink quite a bit of the rice wine ...

You are right, I don't need sugar, but I just always added it because I wanted fermentation to start early and ward off any unwanted bacteria. I guess the mold fed off of that first and then the high alcohol content resulting stopped them from breaking down more rice starches?

I tried a bit flavoured with syrup. It makes for a very strong fermented rice dessert, but it tastes good

What do you suggest that I do?

trbig

Well-Known Member

- Joined

- Feb 11, 2013

- Messages

- 337

- Reaction score

- 96

OK, it's been a while since I posted here, but I have learned a few things. I make the rice wine both with and without the red yeast rice. For traditional wine according to some Chinese friends, you use:

10 lbs long grain sweet rice

One 12 oz package of red yeast rice

One yeast ball per pound of uncooked rice.

When done cooking rice, add 2 gallons of cold water in a 5 gallon or bigger bucket. Soak the yeast balls in warm water for a while. It makes them easier to break up. Add red yeast rice and yeast ball mix and stir well. The first couple days, I open the lid and stir it up once a day.

Pretty simple but here's what I have learned. Every time I have made this in the house at room temp, I get a sour wine. Talking with my Chinese friends, they traditionally don't make rice wine until the end of October when it is cooler. The BEST wine I ever made was last year when I used just cooked sweet rice and yeast balls with no additional water. I left the bucket out on my garage floor for a couple months where it was in the low 30's F for most of the time. The wine came out sweet and SUPER STRONG.. guessing @ 20% because a small 6 oz bottle will mess you up. I filtered all the solids out into a glass carboy and put that back out in the garage for another month or so.

I used a racking cane and filled a bunch of small bottles, corked them, then left them with the corks up. What was left in the carboy, I dumped into a couple half gallon jars and put those in the fridge. The solids will continue to drop out and leave clear wine where you can gently pour it off several times over severa weeks until just solids remain.

The red yeast rice recipe above with additional water makes a less potent, but still strong, dry wine. No additional water makes sweet, tasty, rocket fuel. lol. A year later, it still tastes very "alcoholy". If you keep it out of sunlight, I don't see any reason you can't age this for several years... if you can keep your hands off of it to do so.

So.. many recipes and ways, but try a cold-made batch and you won't be sorry. Cold doesn't seem to bother the yeast in these yeast balls. it may slow them down a little, but I've read many stories of blown up bottles in the fridge because this yeast keeps on truckin' in the cold if you put it there before it's done.

10 lbs long grain sweet rice

One 12 oz package of red yeast rice

One yeast ball per pound of uncooked rice.

When done cooking rice, add 2 gallons of cold water in a 5 gallon or bigger bucket. Soak the yeast balls in warm water for a while. It makes them easier to break up. Add red yeast rice and yeast ball mix and stir well. The first couple days, I open the lid and stir it up once a day.

Pretty simple but here's what I have learned. Every time I have made this in the house at room temp, I get a sour wine. Talking with my Chinese friends, they traditionally don't make rice wine until the end of October when it is cooler. The BEST wine I ever made was last year when I used just cooked sweet rice and yeast balls with no additional water. I left the bucket out on my garage floor for a couple months where it was in the low 30's F for most of the time. The wine came out sweet and SUPER STRONG.. guessing @ 20% because a small 6 oz bottle will mess you up. I filtered all the solids out into a glass carboy and put that back out in the garage for another month or so.

I used a racking cane and filled a bunch of small bottles, corked them, then left them with the corks up. What was left in the carboy, I dumped into a couple half gallon jars and put those in the fridge. The solids will continue to drop out and leave clear wine where you can gently pour it off several times over severa weeks until just solids remain.

The red yeast rice recipe above with additional water makes a less potent, but still strong, dry wine. No additional water makes sweet, tasty, rocket fuel. lol. A year later, it still tastes very "alcoholy". If you keep it out of sunlight, I don't see any reason you can't age this for several years... if you can keep your hands off of it to do so.

So.. many recipes and ways, but try a cold-made batch and you won't be sorry. Cold doesn't seem to bother the yeast in these yeast balls. it may slow them down a little, but I've read many stories of blown up bottles in the fridge because this yeast keeps on truckin' in the cold if you put it there before it's done.

cuisinechemist

Member

- Joined

- Sep 3, 2016

- Messages

- 14

- Reaction score

- 0

Will try that.Start a new batch, ARL and rice are pretty cheap. Follow the instructions I posted. If you can't maintain 100F any other way put in your oven with just the light on. I recommend 24 hours.

But I also ended up pasteurizing my last batch and adding some syrup. With some time and some sugar, I'd say it tastes pretty good now and doesn't really burn anymore. I can taste the fruitiness and rice again and it is definitely higher in alcohol than my previous batches. Definitely going to finish drinking it (eventually).

Start a new batch, ARL and rice are pretty cheap. Follow the instructions I posted. If you can't maintain 100F any other way put in your oven with just the light on. I recommend 24 hours.

Does keeping the light on provides it some temperature? Its winters here and the temperature is running around 20C.

And chonas, do you know how to brew beer? or ginger ale?

I know how to malt wheat or barley But what kind of yeast to use? Will those yeasts i show'd you in one of my previous posts work for beer?

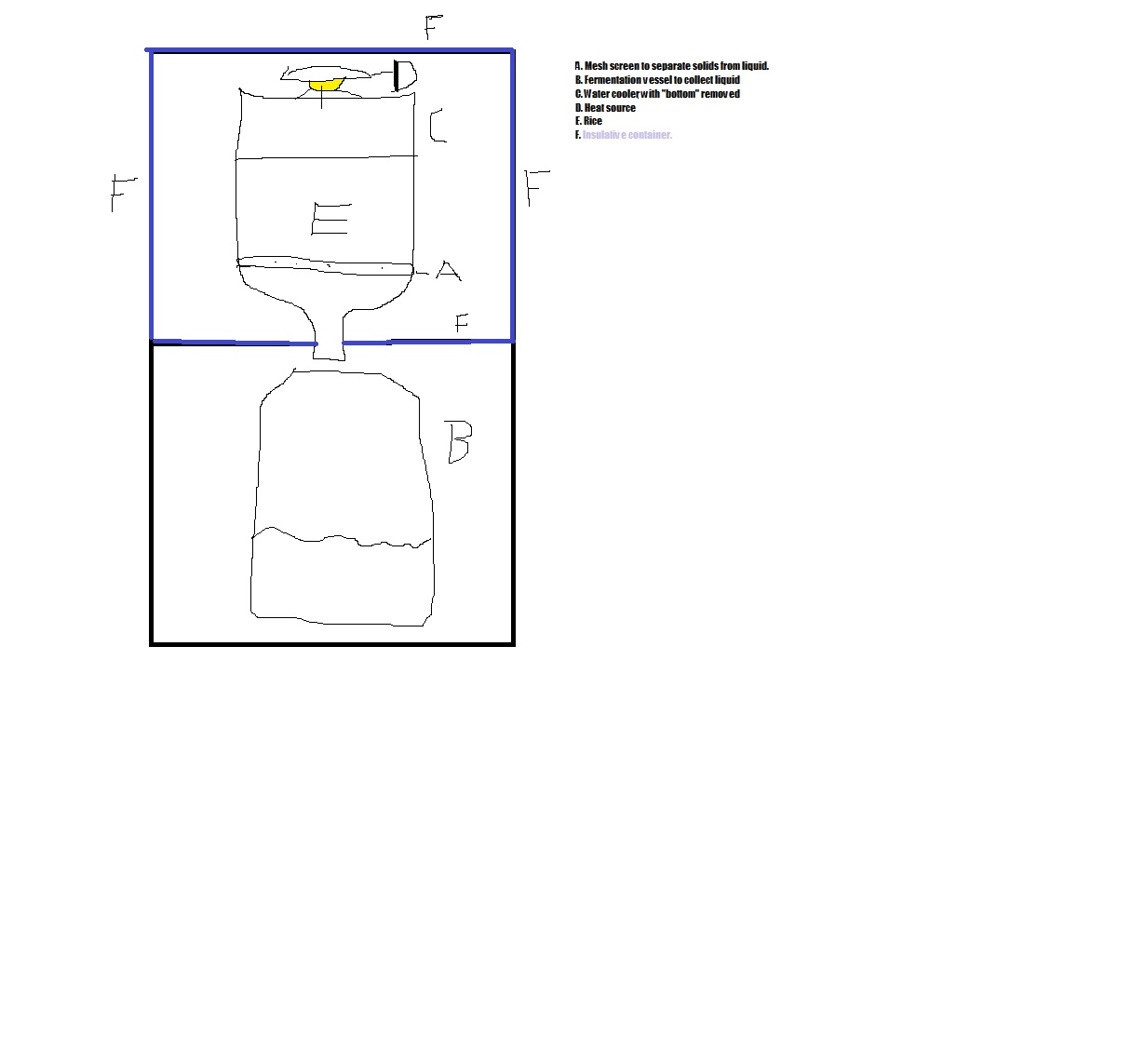

Okay. This is the 3rd week post on my rice wine. I had done 2 batches: water cooked and steam cooked.

Both the batches turned out very tart.

The steamed cooked rice has less tart and a lot of alcohol. I don't have a hydrometer to measure. The steamed cooked batch was 310grams of short grain rice. Amount of liquid yeilded is about 350ml. The rice grains appeared as if they were eaten 'inside out', only the outer shells remained. Flavour is very tart, very sour, like that of a sour red wine.

Boiled cooked batch turned out even more Sour, with a little bitterness. I tasted some with a spoon and immediately threw it. This batch was not drinkable.

I have attached pictures of this batch in here, the one with clear glass jar. Rest all the images are of steamed batch.

Will I be doing this again? Probably not. I am not a drinker, just occasional light drinking. Concept of rice wine intrigues me, so I tried it. But I will try a big batch of only steamed rice with arl. Will probably use 1Kg rice in it.

Both the batches turned out very tart.

The steamed cooked rice has less tart and a lot of alcohol. I don't have a hydrometer to measure. The steamed cooked batch was 310grams of short grain rice. Amount of liquid yeilded is about 350ml. The rice grains appeared as if they were eaten 'inside out', only the outer shells remained. Flavour is very tart, very sour, like that of a sour red wine.

Boiled cooked batch turned out even more Sour, with a little bitterness. I tasted some with a spoon and immediately threw it. This batch was not drinkable.

I have attached pictures of this batch in here, the one with clear glass jar. Rest all the images are of steamed batch.

Will I be doing this again? Probably not. I am not a drinker, just occasional light drinking. Concept of rice wine intrigues me, so I tried it. But I will try a big batch of only steamed rice with arl. Will probably use 1Kg rice in it.

Goodness. I hate to ask basic questions like this, but nearly 600 pages of possible revisions to the original recipe, plus the scientific details regarding yeast/enzyme strains, temperature, and alcohol production is a little overwhelming. Could someone please clarify a few of these for me?

Is steaming, boiling, or soaking best?

What's the difference between using red yeast rice and leaving it plain?

Mold seems to be fairly standard in this... Is there such a thing as too much or perhaps bad varieties?

Should the rice be stirred or just left for the 21-24 days?

What will happen if I don't pasteurize...Really dry alcohol or vinegar?

Is steaming, boiling, or soaking best?

What's the difference between using red yeast rice and leaving it plain?

Mold seems to be fairly standard in this... Is there such a thing as too much or perhaps bad varieties?

Should the rice be stirred or just left for the 21-24 days?

What will happen if I don't pasteurize...Really dry alcohol or vinegar?

Steaming.

RYR = more fruity, more hangover.

Too much not really an issue, Rhizopus and Aspergillus oryzae are both acceptable.

If it's a small batch you can leave it, larger batches require agitation, if using ARL or yeast ball and not a standalone mold you'll want to minimize oxygen contamination (just close the container and shake it if possible).

Flavors will change, the effect will be minimal if the rice wine is kept below 60F. Above that temperature, sourness and further fermentation are likely.

RYR = more fruity, more hangover.

Too much not really an issue, Rhizopus and Aspergillus oryzae are both acceptable.

If it's a small batch you can leave it, larger batches require agitation, if using ARL or yeast ball and not a standalone mold you'll want to minimize oxygen contamination (just close the container and shake it if possible).

Flavors will change, the effect will be minimal if the rice wine is kept below 60F. Above that temperature, sourness and further fermentation are likely.

Similar threads

- Replies

- 0

- Views

- 596

- Replies

- 0

- Views

- 530

- Replies

- 16

- Views

- 993

- Replies

- 11

- Views

- 1K