It's been my plan for quite some time to ultimately run a 2 vessel kettle RIMS setup, but I've been acquiring equipment over time to spread out the cost. I started by going electric and using my cooler MLT. Then switched to recirculating eBIAB. I picked up a chapman thermobarrel on sale just before the holidays that I plan to use as an MLT. I finally got stuff setup to use it this weekend and have an autosparge on the way (for the return flow regulation).

So now I've got the kettle, controller, MLT, pump, etc for the whole thing. Here's how it should work:

Any thoughts, advice, critique, etc.? My planned brew day is 3/20, so I've got time to test and tweak. I'm also gonna try brewfather for first time too. I've been using brewer's friend, but thought I'd give brewfather a shot to see if I like it. Nothing like changing everything at once to ensure a smooth brew day!!!!

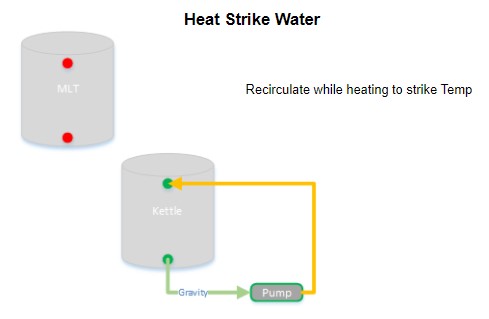

So now I've got the kettle, controller, MLT, pump, etc for the whole thing. Here's how it should work:

- Chapman thermobarrel with false bottom for MLT. I'll put the grains in dry and underlet by pumping from the kettle into the outlet port of the thermobarrel. I'll pump full volume to MLT.

- After underletting, I'll stir and let rest for 10-15 mins.

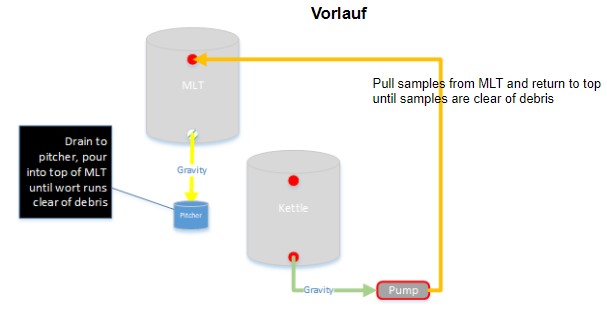

- Then I'll vorlauf...gravity draining to a pitcher until I get clear wort.

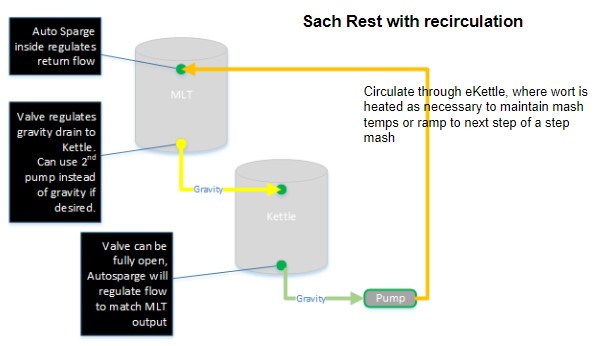

- Then I'll run the MLT outlet to the kettle return (Brewbuilt kettle with notched lid, I have a hose with SS float).

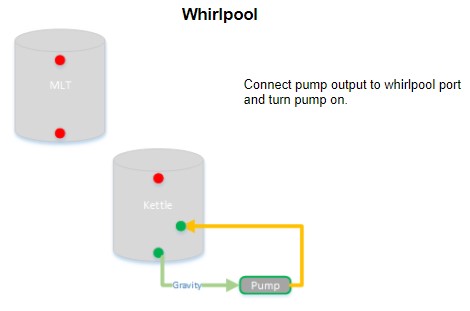

- Run the kettle out to the pump, then pump output back to the thermobarrel return (with autosparge).

- During recirc, I'll gravity drain from MLT to kettle, using the MLT valve to regulate recirc flow.

- Kettle will heat wort and circulate back to the MLT via pump/autosparge which will match the flow of the MLT drain

- Temp for controller will be at the kettle outlet, so temp of wort in kettle should be mash temp (or a degree or two higher if necessary).

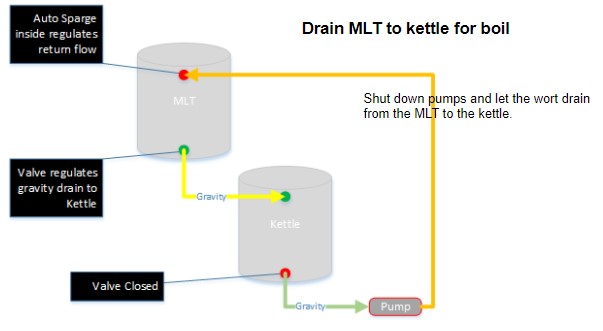

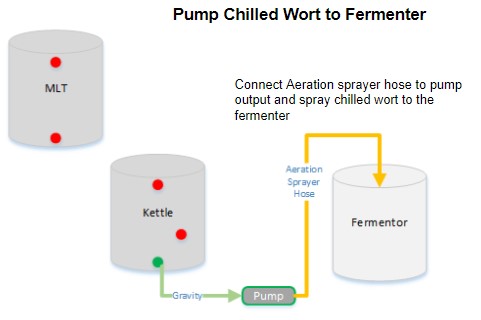

- When I'm done with the mash, I'll turn off the return pump and let MLT drain to kettle

- Boil as usual when draining is complete.

Any thoughts, advice, critique, etc.? My planned brew day is 3/20, so I've got time to test and tweak. I'm also gonna try brewfather for first time too. I've been using brewer's friend, but thought I'd give brewfather a shot to see if I like it. Nothing like changing everything at once to ensure a smooth brew day!!!!