Islandboy85

Well-Known Member

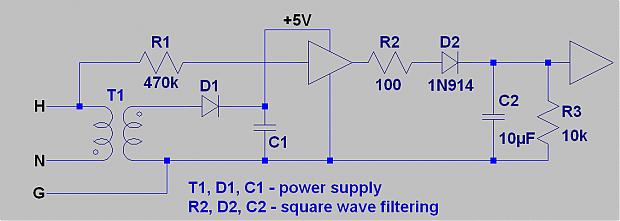

I'm drawing a logic circuit up to control a safety relay that prevents the SSR from energizing the heating element in my HEX if the pump isn't running, the float switch isn't tripped, and my heating element switch isn't closed. I want to also integrate it as a test circuit that will alert me which item in the logic chain is out bad. My problem is that I don't know how to bring the 110 vac to 5 vdc for the logic circuit since the ICs I have run on 5 vdc. What could I use besides a transformer to allow me to use my circuit.