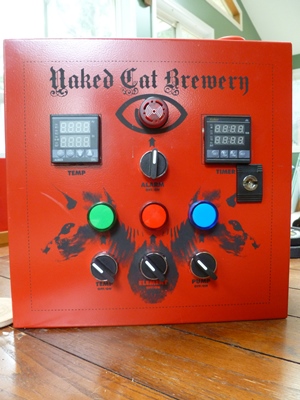

50a 5500 2 Element 4 outlet BCS 460

Would anyone be able to help me take something like this one (I'll be using a BCS-462), and show me how to add control for 2 (so I can see how multiple are connected) automatic valves from the following link? https://www.oscsys.com/store/product/291 - obviously, I'll be adding a 12VDC power source inside the panel.

Also, won't switching these elements to "manual" effectively just run them at 100%? I guess it wouldn't necessarily be a problem for the BK, but the HLT seems to me like it wouldn't be too useful. Would it be reasonable to throw in 2 PIDS for the manual modes of the HLT and the MLT pump, and a PWM for the BK?