First thing to do is connect your BCS with an Ethernet cable to your home network (router), and then power up the BCS (in that order). You should see the orange led in the BCS's Ethernet connector light up, and then the green led start blinking to show activity.

Your router will assign your BCS an ip address, similar to every other computer on your network. What you need to do is find that IP address so that you can type it into your browser to bring up the BCS. For example, if your router gives the BCS an ip address of 192.168.0.10, then in Firefox you type

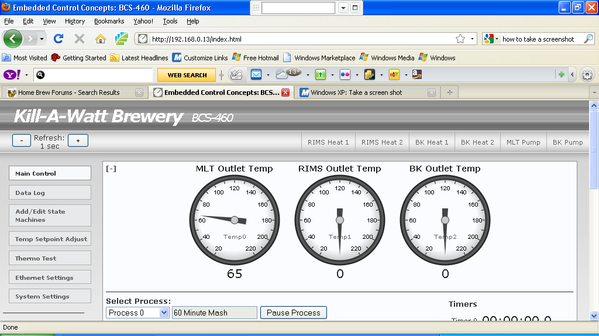

http://192.168.0.10 into the url bar, and the BCS's control screen will pop right up.

But, we have to be able to find the BCS on the network. I'm sure there is someone out there that could write a quick utility that would scan your home network for the BCS (please PM me if interested!), but currently no such utility exists. The easiest way to find that IP address is to log into your router, where it keeps a table of connected devices, along with their IP addresses.

You can usually log onto your router by typing http://192.168.0.1 which will bring up the router's configuration page. Look for the BCS, as noted by the MAC address printed on the bottom of the unit.

Alternatively, you can connect the BCS directly to your computer to bypass all of the network stuff, in which case it always assigns itself a known address. But in that case you would not be able to access it from other computers on the network, which is IMHO one of the coolest features of the BCS.

Some more info:

http://www.embeddedcontrolconcepts.com/wiki/index.php?title=Can't_Connect_to_the_BCS