- Joined

- Aug 7, 2014

- Messages

- 321

- Reaction score

- 182

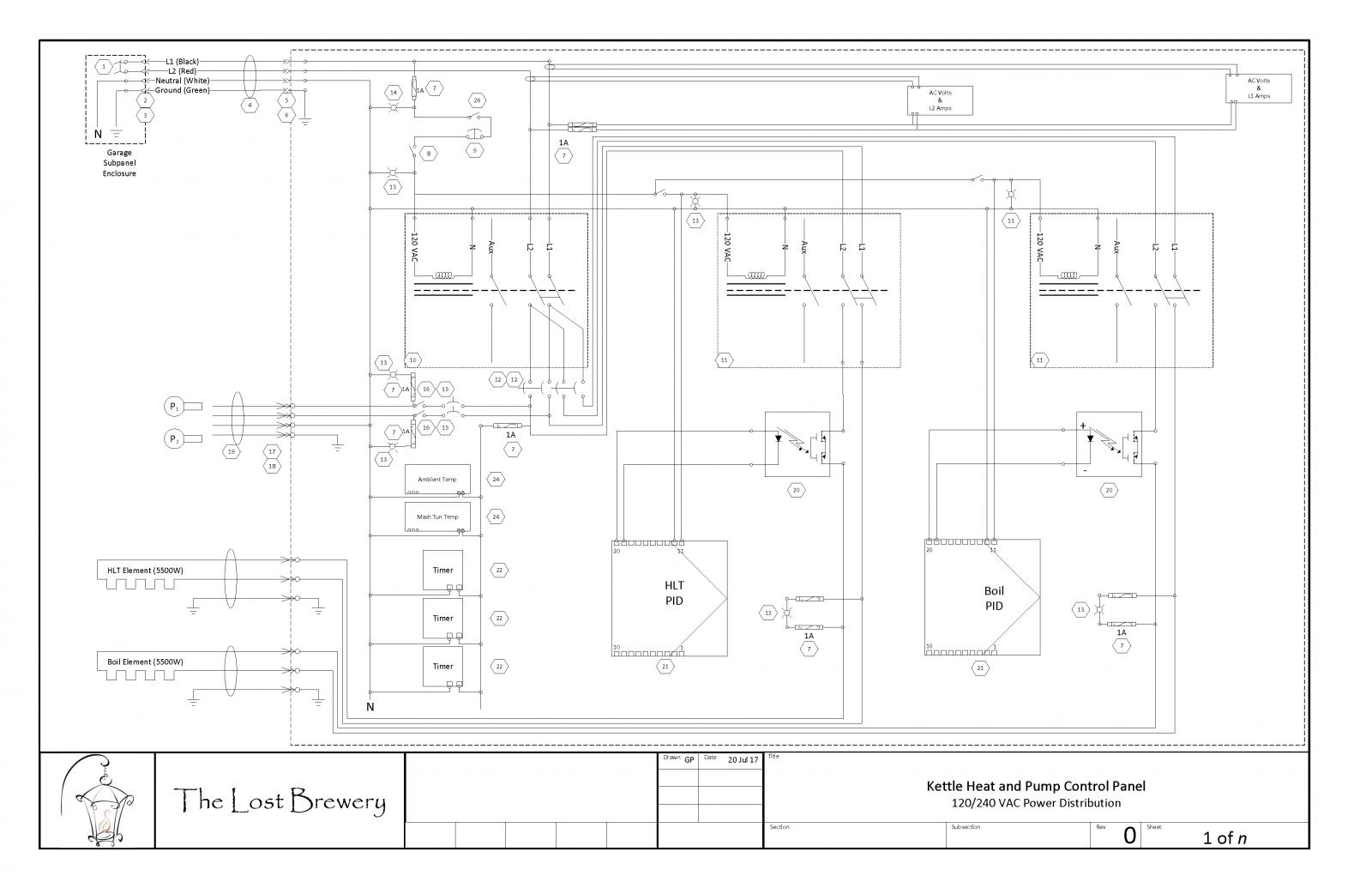

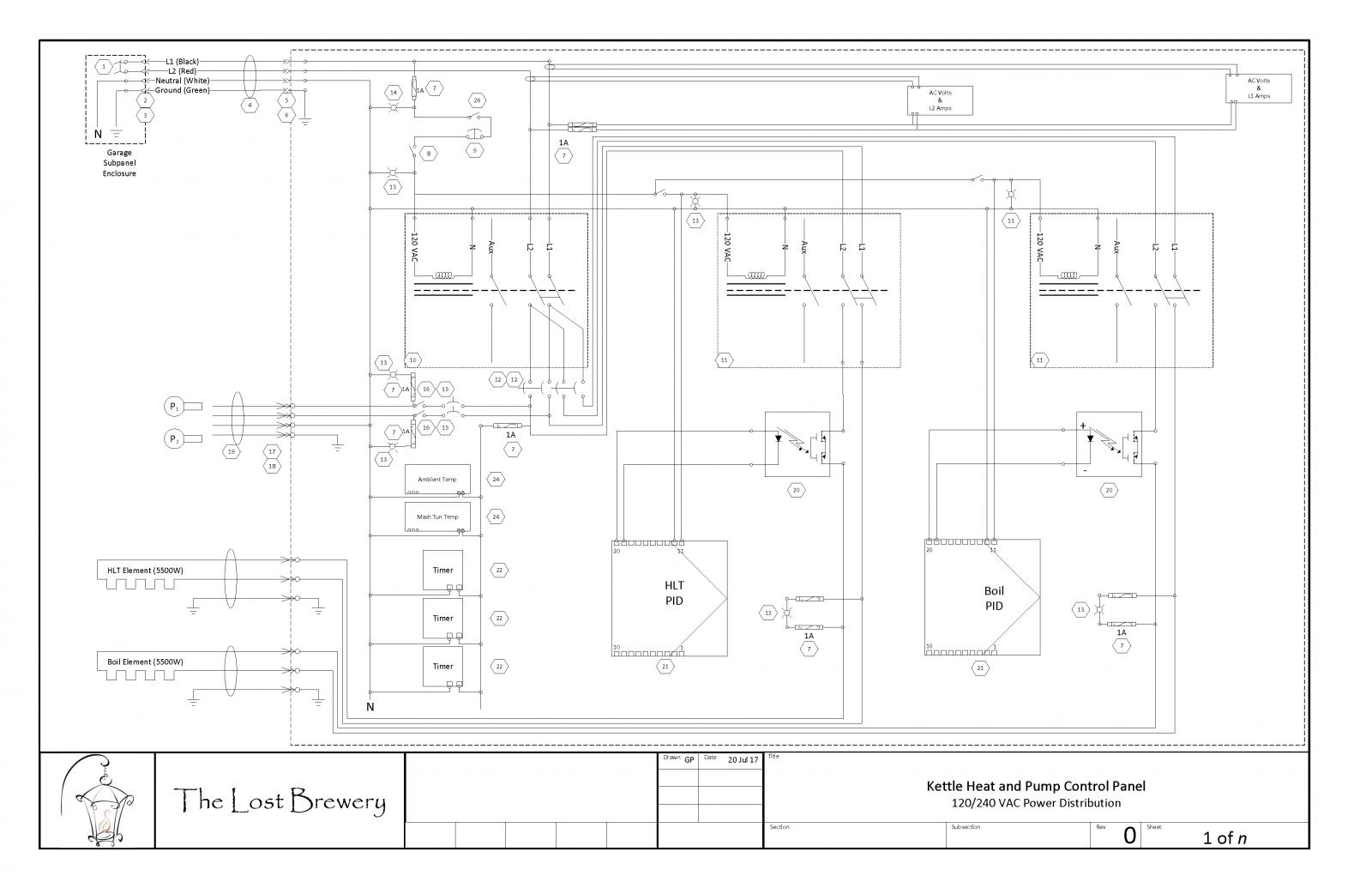

I posted in the Electric brewing forum and on Kal's site a few days ago about a panel I've been working on that is based on Kal's outstanding design, but incorporates a couple of things that I thought would be "nice to haves" for what I'd like to brew with. That design has come along nicely, and the latest iteration is attached. The only update for this round is an improvement in the metering. Now, the meters both read bus voltage, and are split so that one meter reads L1 and the other reads L2. They are also powered before the contactors, so they are on full-time, and I can always see the difference in current between L1 and L2.

Today, I was skipping around between the Electric Brewery forum and the HBT forum, and I fell down a Raspberry Pi rabbit hole. I also read Kal's sticky post about why he opted to not include automation of any kind, and his points are valid, especially regarding long-term support for a specific automation ecosystem.

So what I did was add the capability of switching between manual panel face control of a pair of PIDs and a pair of pumps and automated control via a Raspberry Pi system. I added one 3-position center-off single pole switch, two DPDT relays, one DPST relay, and two SPST relays. I think that as far as power and relay coils are concerned, it is a functional design. That drawing is also attached.

I still have to draw a sensor/signal diagram. I don't know if it will be easier to use a 4PDT relay to switch the output of a 4-wire PT100 sensor or add a second thermowell on each vessel. I still have to think that one through.

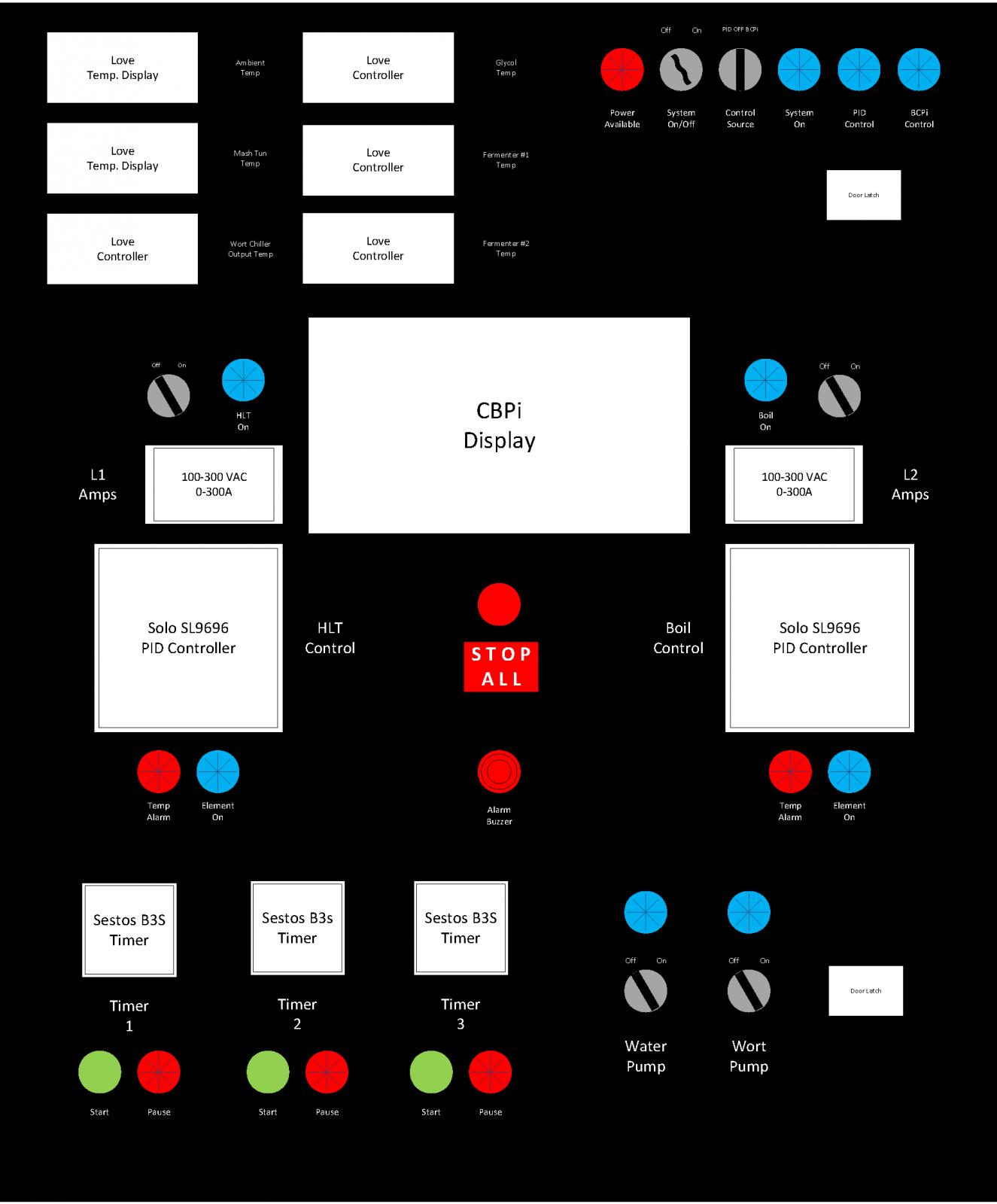

I also have to see if I can shoehorn a 7" touchscreen display and another 22mm switch onto the enclosure door.

Today, I was skipping around between the Electric Brewery forum and the HBT forum, and I fell down a Raspberry Pi rabbit hole. I also read Kal's sticky post about why he opted to not include automation of any kind, and his points are valid, especially regarding long-term support for a specific automation ecosystem.

So what I did was add the capability of switching between manual panel face control of a pair of PIDs and a pair of pumps and automated control via a Raspberry Pi system. I added one 3-position center-off single pole switch, two DPDT relays, one DPST relay, and two SPST relays. I think that as far as power and relay coils are concerned, it is a functional design. That drawing is also attached.

I still have to draw a sensor/signal diagram. I don't know if it will be easier to use a 4PDT relay to switch the output of a 4-wire PT100 sensor or add a second thermowell on each vessel. I still have to think that one through.

I also have to see if I can shoehorn a 7" touchscreen display and another 22mm switch onto the enclosure door.