melville

Well-Known Member

- Joined

- Sep 4, 2016

- Messages

- 422

- Reaction score

- 336

Being that we are getting such a noticeable presence of t58 even pitched at such extremely low ratio suggests that t58 grows and gets to work very fast. This could be beneficial to o2 scrubbing during refermentation. Although i still don't understand why they would be pitching additional yeast for refermentation at all. There should be plenty of the primary yeasts left for a beer that is being cranked out in 2-3 week turnaround.

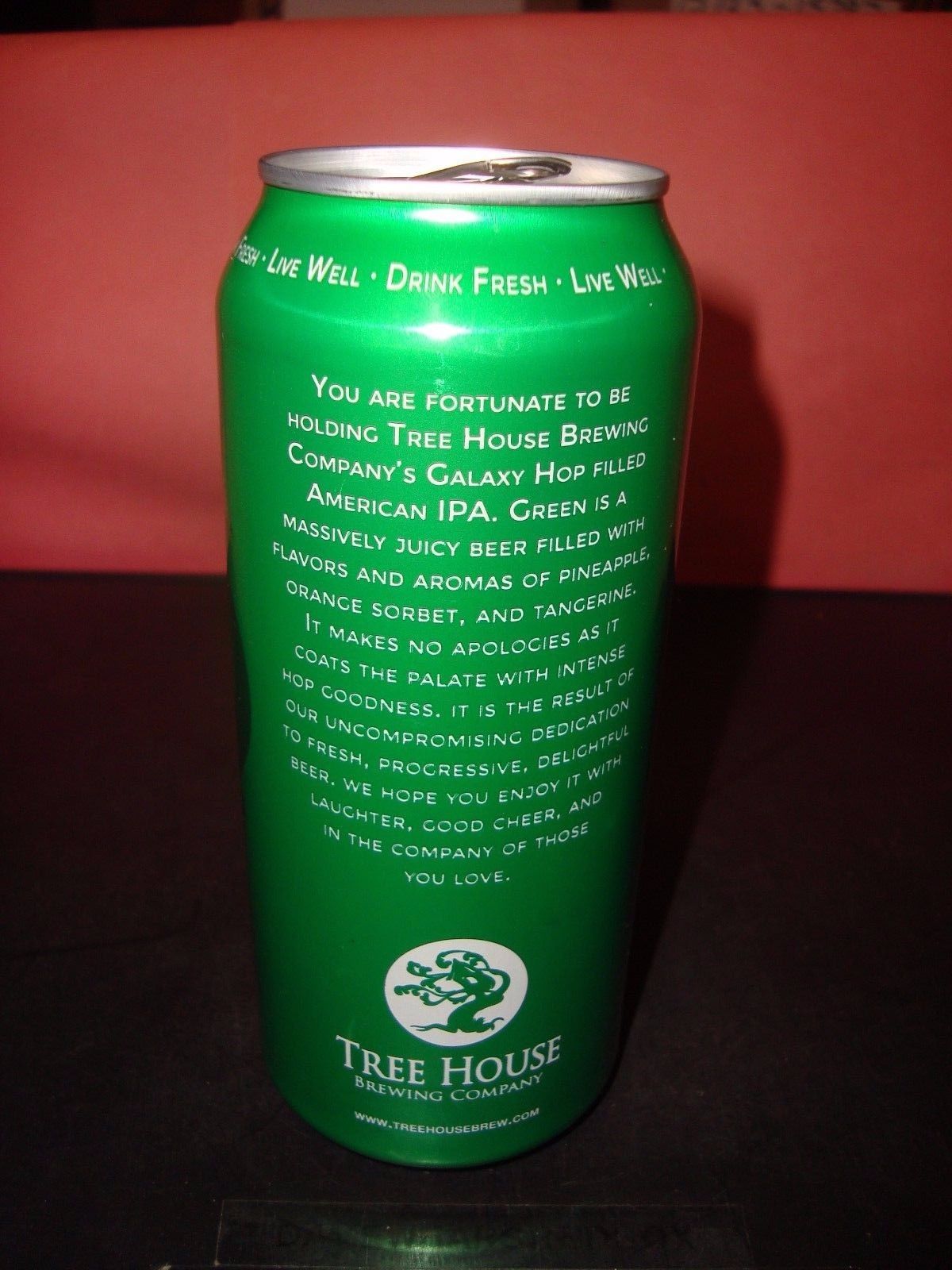

This naturally carbing thing has been driving me nuts, so I asked about it in the pro brewer Reddit. Got a few responses, but their scenarios are different one did add priming sugar in a tank, mix then put into bottles/kegs and the packaged beer referments with the yeast already in the beer. One specifically mentioned it wouldn't be ideal for hoppy beers, because it would add at least a week and probably two. None of the answers seem to grasp the concept of my example: putting already conditioned (and cold) beer into cans that are sold to customers and drinkable immediately (vs packaged, sit for two weeks, sell)