Anthony_Lopez

Well-Known Member

Lets assume flow rate is the same across the board, regardless of pumping or gravity.

A copper tube enclosed in PVC pipe.I would agree as for the plate exchanger. What would be your definition for a tube in shell application in home brewing?

It is the same principle. There are several differnent types of tube in shell.its actually not the same principle.

A tube in shell would be in an enclosed pipe, however there is no way for the counterflowing liquids to be controlled. Yes, you can have water going in the bottom of the shell and out the top of the shell while the wort flows through the tube from the top to the bottom output, you are not forcing a counter-flow exchange across the entire surface area of the tube. This "tube in shell" would be a hybrid chiller, which is less efficient.

Water pressure ensures that you are getting a full counter-flowing heat exchange inside a CFC.

Is this really necessary given that your typical CFC or plate chiller can take the wort from boiling to 75-80 ish in one pass(given that the cooling water is proper temp)?

Who cares?

the whole idea of this is to try and come up with a cfc that doesn't need a pre-chiller. If everyone just accepts what they already have, then we would lose all drive to try and increase efficiency in every thing we do.

Convoluted CFC's already exist which do increase the turbidity of the cooling water.

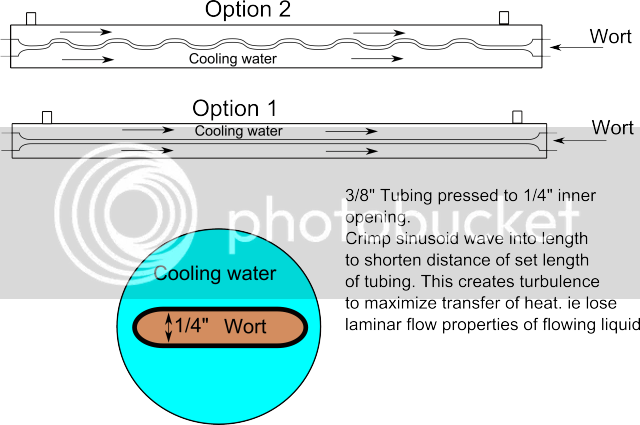

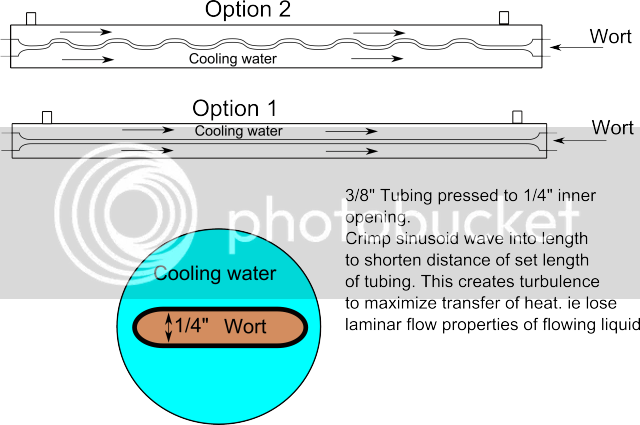

When I read about CFC chillers I can't help but think of this idea. Basically it reduces the cross-sectional distance in one direction, exposing the wort equally to the cooling water. Therefore a lower thermal gradient across the wort as it flows.

This is similar to your water/wort/water idea but simplifying the design.

I added the sinusoidal curves to cause turbulence and hopefully reduce laminar flow issues.

The original tubing would have regular round ends, just crimped midsection. I had even thought about making a U so that the length of the chiller would be ~ 1/2 as long.

I like these geek debates on how build a better mouse trap!! Keep it up

I completely agree JMD... comments like "who cares" kind of negate my entire career...

didn't mean to tip over your apple cart, sally.

didn't mean to tip over your apple cart, sally.

I kindly disagree. That's like saying we can't make our automobiles more efficient without using a different engine. Cars have become so efficient over the past 20 years, and it's because we keep trying to improve an existing design.

I'd have to kindly disagree with you too.. My first car, 1980 citation, would get 27mpg. Now a 2009 corsica with the same motor (3.0 V6) get 27mpg...??

Where's the benefit of 28 years of R&D? Cars are getting no better mileage now than they were in the 80's, it just costs more so we think about it more.

As to the chiller (CFC or not) You can only get as cold as the source water no matter what design or how long or how many tubes you run it through.

I'd have to kindly disagree with you too.. My first car, 1980 citation, would get 27mpg. Now a 2009 corsica with the same motor (3.0 V6) get 27mpg...??

Where's the benefit of 28 years of R&D? Cars are getting no better mileage now than they were in the 80's, it just costs more so we think about it more.

As to the chiller (CFC or not) You can only get as cold as the source water no matter what design or how long or how many tubes you run it through.

here we go!

That would work well in a tube in shell design I'd bet...

Please read the prior posts, the discussion is not whether you can "magically" cool water to below the temperature of the source, it's how you can cool it to that temperature more efficiently.

If your numbers are correct, could you also tell me the Horsepower/torque for both models? I have a hunch that the 2009 corsica has a bit more power.

The car is one example, if you'd rather have a closed mind about these types of things, then go for it. I for one would rather improve than conform.

The whole point of this forum is to discuss better ways of making beer. If you go into a discussion claiming that 28 years of R&D was a waste of time & money, then prove it.

Don't assume just because I'm from NY I'm a typical "New Yorker". We're trying to have an interesting discussion, and you are just trying to prove why we're wrong instead of adding anything to our conversation.

You don't have to explain the point of this forum or thread, I understand the principle. I also didn't say 28 years of R&D was a waste of time. I DID state that we are getting no better mileage based on my experience and knowledge of then vs. now mileage statements. You want to know the horsepower etc. of said models here you go;

1981 Chevy 60* v6 found in Citation x-11

170.87ci, 135hp/165#'s tq. Works out to .78hp per cubic inch.

1993 Camaro v6 (but now 3.4 litre)

207.48ci, 160hp/tq not listed. Works out to .77hp per cubic inch.

Later 2005-2008 V6 models (lumina, malibu, etc) do slightly better, but with larger engines as well.

3.4litre/207ci comes out to .86hp/ci - 3.8litre/231ci comes out to .86hp.ci

So it would seem pretty linear to me as far as R&D goes. Making more power is a byproduct of making a larger motor. If I swing a larger hammer, I can hit harder with same input force.

I'm going to make a pretty reasonable assertion that the mileage factor doesn't change a whole lot in 20-25 years. 18-24 (as posted above) seems to be the mean average I found as well with google.

I will didn't assume you as a typical NY'r, you acted like one. And twice now.

I even used the word "kindly" in my first post quoting you. My mistake.

You quickly jump and react like I was personally attacking YOU. When I simply disputed your basis for comparison.

I have no idea what heat transfer or drag coefficients need to be considered, but I'm not a complete idiot either and don't really appreciate you presuming that I am. Maybe you should push that chip off your shoulder before you reply to people.

Hopefully the original topic will resume.

Brad

Sweet Jesus... someones gonna scorch the grains with all these flames... Lets try to keep this conversation/discussion within the realm of my intent. If not, I'll just ask for it to be locked and deleted. I can do my own experiments with these HEX designs, I just thought it would be nice to let everyone in on what we have been talking about at work.

Enter your email address to join: