Thats it. No help needed finding leaks or fixing anything. I'm checking to see if there is some in-line apparatus available to prevent a keg leak from totally draining the CO2 bottle. I have a 20lb bottle to a 4valve gas block, to 4 kegs in the kegerator. My new beer that I like had a loose keg post and it drained the whole c02 bottle. The gas block fortunately prevented the keg that will not die, of a brown that i hate, from emptying. This is now my only draft beer.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

In-line solution to Prevent CO2 bottle leak down ?

- Thread starter WesBrew

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

What you are looking for is a clairvoyant gas valve that is able to assess all parameters down stream and shut down if it thinks something is amiss.

Unfortunately, to my knowledge, such a "Holy Grail" device does not yet exist...

Cheers!

Unfortunately, to my knowledge, such a "Holy Grail" device does not yet exist...

Cheers!

Broken Crow

Ale's what cures 'ya

- Joined

- Oct 12, 2020

- Messages

- 2,066

- Reaction score

- 2,610

I'll take you at your word and the only possibly annoying nag I'll state is this: Keep a spare tank on hand!Thats it. No help needed finding leaks or fixing anything

The only real apparatus to prevent leaks is between your ears and developing the pedantic habit of close attention to detail every time to so much as touch your system. I dunno if you're using traditional lines or EVABarrier, but if the latter, though most folk who use it (myself included) love it, I have had it leak when I've bent the hose at the connector 'too much', even with the little blue retainer clips installed. No system is completely perfect, so we need to test every keg, line, tap and junction every we use them. I learned that both from my first 2 gas leaks and, like you, a loose post which amazingly did not leak (or at least not very much) until the keg had kicked and I discovered it while cleaning.

Just curious though; Can you post pics of your system, even though that means a lot of us will annoy you by filling this thread with stuff you already know, but just maybe when you trace the problem we'll all have a clearer picture of things to watch out for ourselves?

Sorry about your lost gas, hope you can get a replacement soon.

I figured. I couldn’t find anything. I was thinking more like something that prevents constant flow of gas. Either it doesn’t exist or it costs more than my breweryWhat you are looking for is a clairvoyant gas valve that is able to assess all parameters down stream and shut down if it thinks something is amiss.

Unfortunately, to my knowledge, such a "Holy Grail" device does not yet exist...

Cheers!

Carbing a new batch would "look like" a leak to the imagined widget. So, detecting leaks is hard-to-impossible to automate. A scale under your CO2 bottle will help you to become aware of gas leaks (and gas use!) before the gas is all gone, but still requires you to pay some attention.

A simple shutoff valve will prevent leaks but will also prevent carbing . @Broken Crow is right on target.

. @Broken Crow is right on target.

A simple shutoff valve will prevent leaks but will also prevent carbing

The post was snug I guess when I put keg on and just forgot to do a final tighten. I went futzing around in there 2 days ago to pull out some empties to clean, apparantly really loosened them up.I'll take you at your word and the only possibly annoying nag I'll state is this: Keep a spare tank on hand!

The only real apparatus to prevent leaks is between your ears and developing the pedantic habit of close attention to detail every time to so much as touch your system. I dunno if you're using traditional lines or EVABarrier, but if the latter, though most folk who use it (myself included) love it, I have had it leak when I've bent the hose at the connector 'too much', even with the little blue retainer clips installed. No system is completely perfect, so we need to test every keg, line, tap and junction every we use them. I learned that both from my first 2 gas leaks and, like you, a loose post which amazingly did not leak (or at least not very much) until the keg had kicked and I discovered it while cleaning.

Just curious though; Can you post pics of your system, even though that means a lot of us will annoy you by filling this thread with stuff you already know, but just maybe when you trace the problem we'll all have a clearer picture of things to watch out for ourselves?

Sorry about your lost gas, hope you can get a replacement soon.

On a positive note, the mention of backup prompted me to check my old steel unit. Gas! Not much but enough to put this keg back on pressure.

Bracc would reccomend putting your co2 tank on a digital scale that stays on unless you unplug it. Monitor it to make sure it doesnt drop unless you pull a pint, or are force carbing... accuteck sells one on Amazon for under $30 I think w8580-100 is the item number.

Curtis K.

Active Member

- Joined

- Nov 2, 2018

- Messages

- 26

- Reaction score

- 21

Bracc would reccomend putting your co2 tank on a digital scale that stays on unless you unplug it. Monitor it to make sure it doesnt drop unless you pull a pint, or are force carbing... accuteck sells one on Amazon for under $30 I think w8580-100 is the item number.

Made me think of the PLAATO Keg Management System, which didn't seem to have a lot of value to me because I don't need to monitor how many pints I've poured from a keg - it is empty when it is empty...

The PLAATO web site - PLAATO Keg Management System Clearing Sale - shows a CO2 bottle on one of their load cell units. However, it looks like the company is dropping their line of homebrewer products including the Keg Management System. If the system works to monitor CO2 bottles, maybe the product would have been more successful marketed differently.

I figured. I couldn’t find anything. I was thinking more like something that prevents constant flow of gas. Either it doesn’t exist or it costs more than my brewery

There are devices sorta to that end (velocity fuse) in hydraulics and possibly pneumatics but they are more for lock down, so to speak, in a catastrophic failure or major leak event, not slow leak.

a meter of some sort to alarm you when there is a constant flow of gas over time would have been nice. it looks like a scale is the only reasonable option, but you have to be looking at it.

If you have a slowwww leak or would be a matter of checking once and hour or less... if it's a steady leak you will likely see it drop steadily, the scale I mentioned will weigh to .01oz

the ability to monitor CO2 cylinders would be the most obvious and useful feature.Made me think of the PLAATO Keg Management System, which didn't seem to have a lot of value to me because I don't need to monitor how many pints I've poured from a keg - it is empty when it is empty...

The PLAATO web site - PLAATO Keg Management System Clearing Sale - shows a CO2 bottle on one of their load cell units. However, it looks like the company is dropping their line of homebrewer products including the Keg Management System. If the system works to monitor CO2 bottles, maybe the product would have been more successful marketed differently.

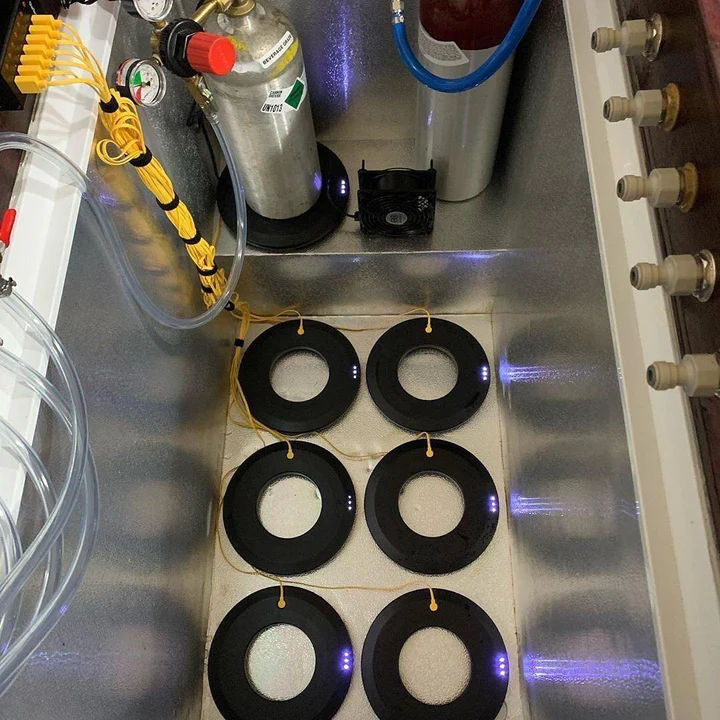

View attachment 832985

My setup is not fancy; Tapits sitting on the keg posts of a couple kegs, tank in there with the kegs. I carb in the keg with sugar before they go in the freezer.

With everything carbonated, I turn the inline valve off on my CO2 tank. If everything is tight, all’s good until I come back. When I pour a mug, I reach over and turn the valve on briefly to charge the system back up, then turn it off again. It’s not elegant, but it works. It’s no different than a bottle carbed up and sitting in the fridge.

I lost one tank a couple years back before I started doing this when a hose slipped a barb and clamp.

Since doing this, I’ve only lost one keg when a party tap froze and opened enough to empty the keg; it contained carbonated water. That really didn’t cost me anything but the time to clean up the mess. That’s also when I started looking into the Tapit to replace the party taps.

I could still lose a keg if the Tapit failed. The beer would flow until the pressure equalized. I used to pull the party taps off my kegs at night after the water keg loss, but that is hard on the o-rings and is messy with the spit of beer lost from the post as the poppet reseats.

Again, it’s not as elegant as a full keezer build with all the whistles and bells, but I still get my cold beer. For me, turning the valve on/off is a lot easier than rinsing yeast out of a bottle.

With everything carbonated, I turn the inline valve off on my CO2 tank. If everything is tight, all’s good until I come back. When I pour a mug, I reach over and turn the valve on briefly to charge the system back up, then turn it off again. It’s not elegant, but it works. It’s no different than a bottle carbed up and sitting in the fridge.

I lost one tank a couple years back before I started doing this when a hose slipped a barb and clamp.

Since doing this, I’ve only lost one keg when a party tap froze and opened enough to empty the keg; it contained carbonated water. That really didn’t cost me anything but the time to clean up the mess. That’s also when I started looking into the Tapit to replace the party taps.

I could still lose a keg if the Tapit failed. The beer would flow until the pressure equalized. I used to pull the party taps off my kegs at night after the water keg loss, but that is hard on the o-rings and is messy with the spit of beer lost from the post as the poppet reseats.

Again, it’s not as elegant as a full keezer build with all the whistles and bells, but I still get my cold beer. For me, turning the valve on/off is a lot easier than rinsing yeast out of a bottle.

Close. 8580-110. Only $25 now. 13K people can’t be wrongBracc would reccomend putting your co2 tank on a digital scale that stays on unless you unplug it.. accuteck sells one on Amazon for under $30 I think w8580-100 is the item number.

Broken Crow

Ale's what cures 'ya

- Joined

- Oct 12, 2020

- Messages

- 2,066

- Reaction score

- 2,610

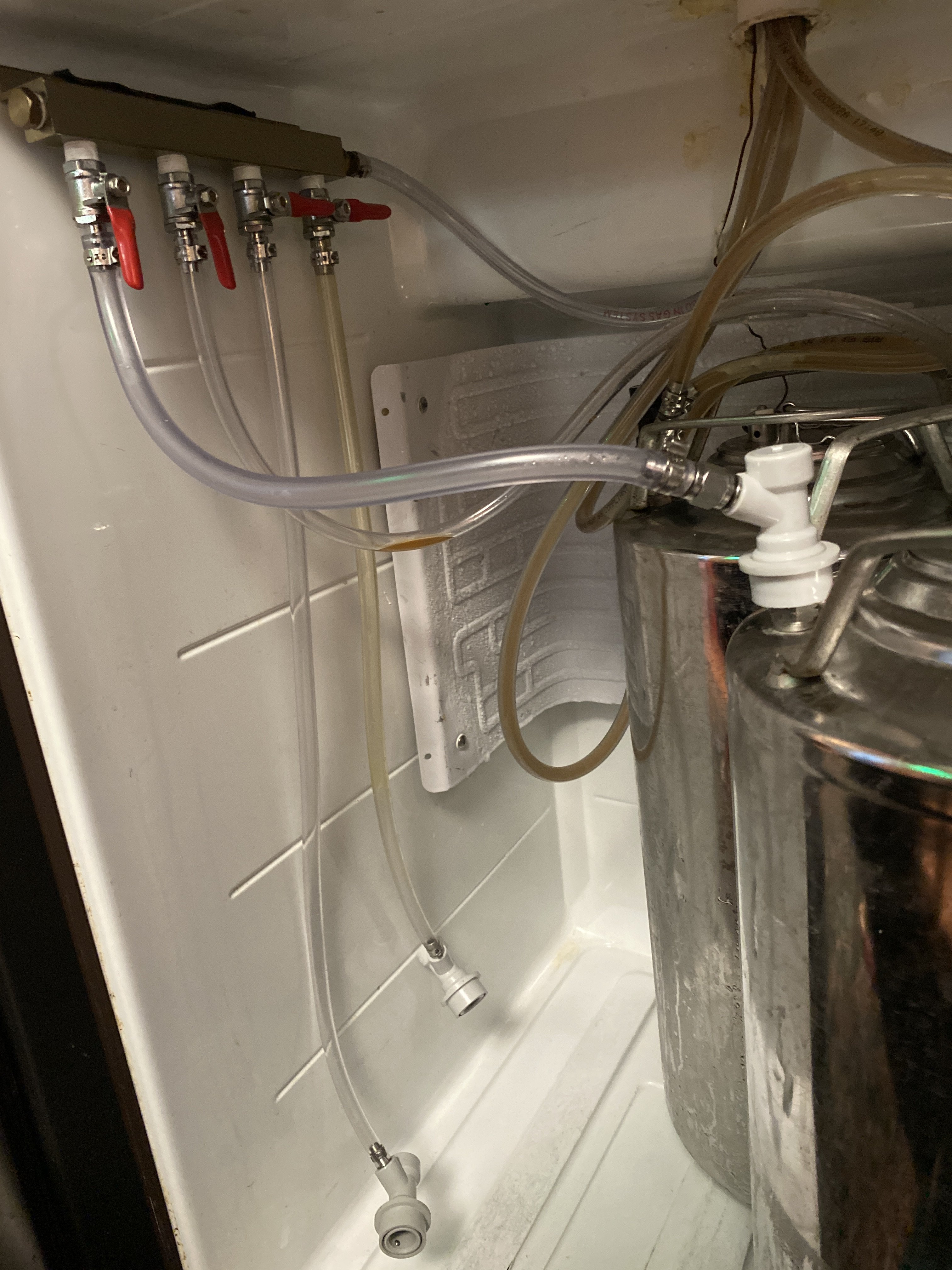

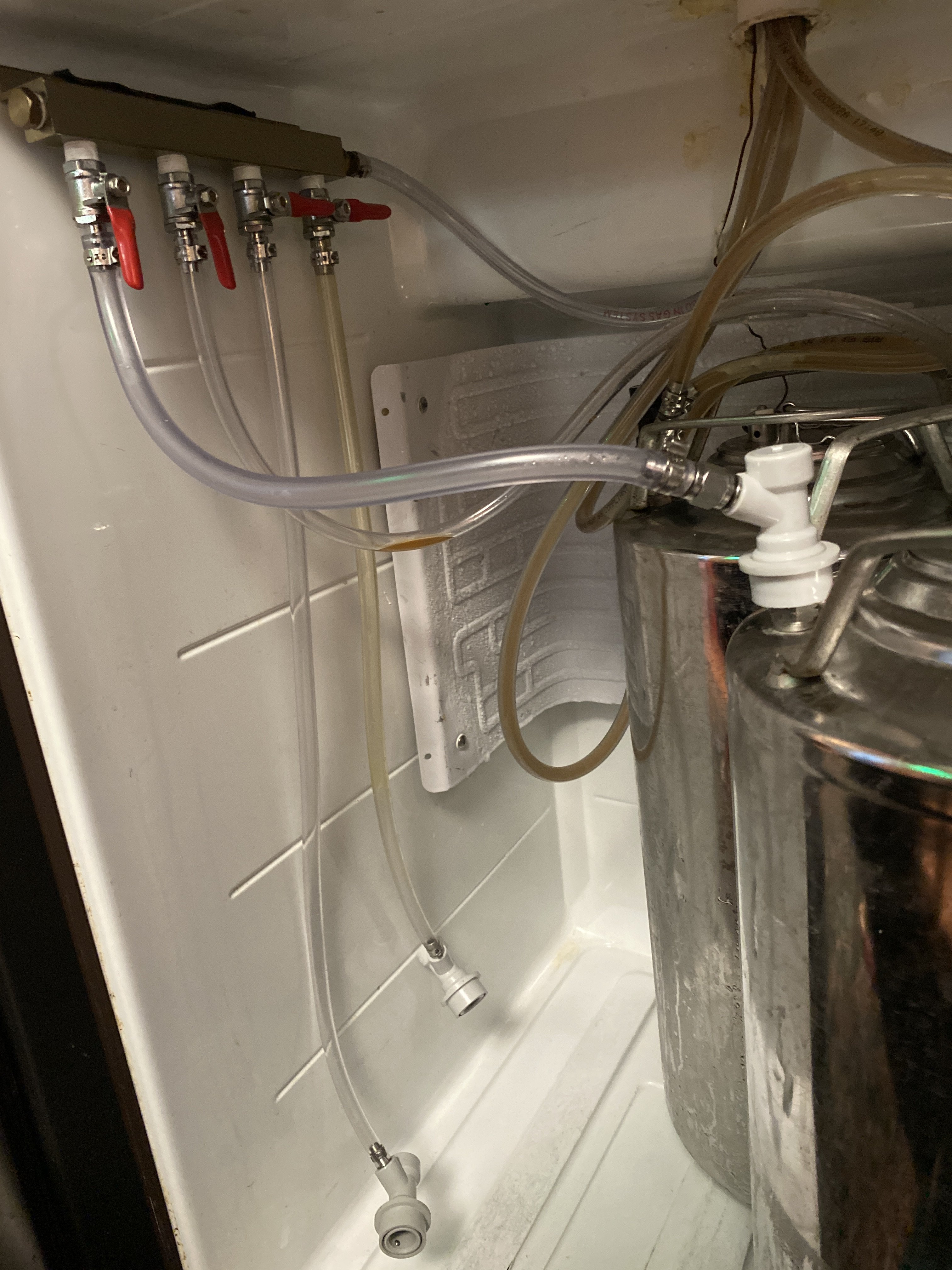

Thanks for posting the pics. I've got a bit of an alarm bell going off in the back of head; I've had various occasions where I've had to use 'larger than ideal' worm-clamps, and an annoyance I've encountered a few times is that when you screw an oversized one too tight, it no longer keeps a circular form and can actually pinch a line which if under pressure, can result in a slow leak....the splay usually occurs right behind the worm-screw and looks a lot like what I see on your first valve:

..Looks like a very oversized clamp on the manifold input too.

Just tryin to be helpful. Please let us know when you find the leak.

..Looks like a very oversized clamp on the manifold input too.

Just tryin to be helpful. Please let us know when you find the leak.

the leak was found at the keg immediately. just posted pics for the heck of it. Agree on the clamps. I was in the process of replacing with Oetiker clamps but ran out of the right size.Thanks for posting the pics. I've got a bit of an alarm bell going off in the back of head; I've had various occasions where I've had to use 'larger than ideal' worm-clamps, and an annoyance I've encountered a few times is that when you screw an oversized one too tight, it no longer keeps a circular form and can actually pinch a line which if under pressure, can result in a slow leak....the splay usually occurs right behind the worm-screw and looks a lot like what I see on your first valve:

View attachment 832991

..Looks like a very oversized clamp on the manifold input too.

Just tryin to be helpful. Please let us know when you find the leak.

Curtis K.

Active Member

- Joined

- Nov 2, 2018

- Messages

- 26

- Reaction score

- 21

Good eyes Broken Crow! I've had that happen too, and now I try to use Oetiker clamps for gas connections.Thanks for posting the pics.

I'd presume someone familiar with something like Arduino could program to take input from an electronic scale or load cell then have it control a solenoid/shutoff valve put at the outlet of CO2 bottle.

If the weight drops by a pound (or whatever) then shut off the CO2.

Of course, one would have to adjust/reset the weight differential monitor every now and then based on expected carbing or dispensing. Potentially could somewhat automate that too if possible to program weight change vs time (or some other relevant flag).

(Patent pending )

)

If the weight drops by a pound (or whatever) then shut off the CO2.

Of course, one would have to adjust/reset the weight differential monitor every now and then based on expected carbing or dispensing. Potentially could somewhat automate that too if possible to program weight change vs time (or some other relevant flag).

(Patent pending

If all my beer is carb'd and roughly steady state, I do leak checks by closing tank valve and seeing if I lose pressure. The high pressure CO2 in the stem is usually enough to hold pressure at steady state for a surprisingly long time.

Take a look at CO2 detectors and air quality monitors. Get a baseline and check it anytime you change out kegs. There's plenty out there that can be monitored on your phone too for $$.

Here's a cheap keychain monitor:

https://www.amazon.com/dp/B0CGLBRGC...ndustrial&sp_csd=d2lkZ2V0TmFtZT1zcF9kZXRhaWwy

Here's a cheap keychain monitor:

https://www.amazon.com/dp/B0CGLBRGC...ndustrial&sp_csd=d2lkZ2V0TmFtZT1zcF9kZXRhaWwy

Last edited:

For clamps, these type may be alternates to consider. The plastic zip clamp or the clamps with liners "Breeze" clamp is a mfg thereof.

Per clamp all but certainly more $ than the crimp/Oetiker, but if you have to buy a crimp tool for just a few connections those other clamp styles may be worth considering.

Per clamp all but certainly more $ than the crimp/Oetiker, but if you have to buy a crimp tool for just a few connections those other clamp styles may be worth considering.

Attachments

It won't stop the gas but a flow meter will show if you have a leak. I use this when I'm force carbing a keg

https://www.amazon.com/100-1000ml-O...gen+air+gas+conectrator,industrial,157&sr=1-1

https://www.amazon.com/100-1000ml-O...gen+air+gas+conectrator,industrial,157&sr=1-1

Take a look at CO2 detectors and air quality monitors. Get a baseline and check it anytime you change out kegs. There's plenty out there that can be monitored on your phone too for $$.

Here's a cheap keychain monitor:

Interesting. Something like that could be useful, even more so if it could be left in the kegerator and bluetooth to phone. I had a pretty good run of no leaks but when they happen, its usually in the kegerator.

Interesting. Something like that could be useful, even more so if it could be left in the kegerator and bluetooth to phone. I had a pretty good run of no leaks but when they happen, its usually in the kegerator.

Here's a cheap keychain monitor:

Last edited:

Good idea!It won't stop the gas but a flow meter will show if you have a leak. I use this when I'm force carbing a keg

But for leak detection a much smaller flow range is needed, such as 0.01 l/min, or perhaps you'd get away with 0.1 l/min.

I don't think there's a true flow meter that could actually detect a "leak"...

Cheers!

Cheers!

Broken Crow

Ale's what cures 'ya

- Joined

- Oct 12, 2020

- Messages

- 2,066

- Reaction score

- 2,610

I saw this years ago and haven't thought about it until just now so I looked it up;

https://www.ontariobeerkegs.com/micro-dbl-inline-leak-detector.htmlI'm wondering if one of those kegland FOB detectors could be modded to do the same thing?

https://www.ontariobeerkegs.com/micro-dbl-inline-leak-detector.htmlI'm wondering if one of those kegland FOB detectors could be modded to do the same thing?

FWIW, put a keg on the bottle last night. Leak check with well-foaming Starsan solution sprayed on fittings revealed a small leak at the regulated pressure gauge connection.

I have doubts any flowmeter-type device capable of reliably recognizing that miniscule amount would have the range to handle a normal flow situation.

I have doubts any flowmeter-type device capable of reliably recognizing that miniscule amount would have the range to handle a normal flow situation.

beren

Well-Known Member

Want to detect a leak? Use a co2 monitor. Won’t matter what the flow rate is if it’s in an enclosed space the numbers will build.

Want to detect a leak? Use a co2 monitor. Won’t matter what the flow rate is if it’s in an enclosed space the numbers will build.

Yeah, I get it.

My recent comment was essentially to that point re. flow-type measurements.

Since someone had to blow up my pic and point out the band clamps I hadn’t gotten to yet. Got off my azz and finished

A CO2 monitor in the kegerator is something I didn’t know about and likely wouldn’t have thought of. That is really the only place I’ve had a leak. Good ideas coming out of this thread

That meter needs roughly .1 lpm to show a flow. That would be a monstrous leak ime...I saw this years ago and haven't thought about it until just now so I looked it up;

https://www.ontariobeerkegs.com/micro-dbl-inline-leak-detector.htmlI'm wondering if one of those kegland FOB detectors could be modded to do the same thing?

Cheers!

You, know you've got beer in your gas line, yes?Since someone had to blow up my pic and point out the band clamps I hadn’t gotten to yet. Got off my azz and finished

The one thing about using Oetiker clamps over barbs is that you can't simply take the lines off to clean and dry them.

That's one of the reasons to use MFL fittings, everywhere.

Or even better, EVA Barrier line with p-t-c fittings.

Didn’t even notice . Sht. looks like I’ll be doing that one over. Whatever can go wrong….

Last edited:

This gauge will measure 100-1000 mL/minute (.1 - 1.0 L/min). Most connect CO2 at night and find an empty bottle in the morning. Some math; a 5lb tank hold 300 liters of CO2. If it empties in 12 hours, 300 liters in 12 hours is 25 liters/hr which is .416 liters/min which this gauge would detect. If it took 24 hours to empty that would be .21 L/m which this gauge would also detect.Good idea!

But for leak detection a much smaller flow range is needed, such as 0.01 l/min, or perhaps you'd get away with 0.1 l/min.

Thanks for the calculations, a 0.1 - 1.0 l/min gauge will show those common, slow leaky flow rates. Yes!This gauge will measure 100-1000 mL/minute (.1 - 1.0 L/min). Most connect CO2 at night and find an empty bottle in the morning. Some math; a 5lb tank hold 300 liters of CO2. If it empties in 12 hours, 300 liters in 12 hours is 25 liters/hr which is .416 liters/min which this gauge would detect. If it took 24 hours to empty that would be .21 L/m which this gauge would also detect.

The gauge should be placed right after the regulator's output, before any manifolds, splitters or Ts.

While on topic of "leaks," I had the PRV on one of my regulators starting to release around 35 psi, although the range of the regulator goes to 50-60 psi. I had a glass rinser attached to that channel, which really needs that higher pressure to do some serious spraying/rinsing. Oh yeah!

We heard it starting to blow off badly at 40-45 psi, so dialed it back, more and more , and ended up using it at 30 psi. Got to see if I can find a higher threshold PRV for that regulator...

Broken Crow

Ale's what cures 'ya

- Joined

- Oct 12, 2020

- Messages

- 2,066

- Reaction score

- 2,610

This is really bugging me... Since the brain injury, I've done my best to re-engage the neural pathways to my lost memory/knowledge/skills; Guided neuroplasticity..and it's worked to some extent. Between 2014 and 2020 I couldn't even comprhend how a screwdriver worked, I could still use one from memory but the intuition and comprhension of it's function eluded me until, in trying to relearn basic electrical systems and design my own BK controller (Thanks for ALL your marvellously detailed post and schematics @doug293cz !!!) a neuron finally reconnected and in an instant I regained a massive amount of basic problem solving skills and much of my basic electical knowledge..literally: POOF! There it was!

Anyway, This thread is exactly the kind of problem I would have siezed on prior to my injury and not rested until solved, so here's where my brain went:

Part of the IR spectrum is absorbed by CO2...One should be able to build a small inline unit, similar to a RIMS tube or inline oxygenation/carbonation unit, but at one end have an IR emitter, adjusted to the CO2 sensitive range, and at the other a simple diode...Due to Brownian Motion, there'll always be some variance which you use as your baseline measurement, when significant more photons are lost, it would indicate a greater mass (owing to the motion of a leak).

This is the sort of thing I would have tried to build before 2014, but I simply no longer hace the knowledge or skills...not to mention; my sense of proportion.

Maybe one of you sound scientific-minded could work with it, or at least tell me that I'm way off track.

Anyway, This thread is exactly the kind of problem I would have siezed on prior to my injury and not rested until solved, so here's where my brain went:

Part of the IR spectrum is absorbed by CO2...One should be able to build a small inline unit, similar to a RIMS tube or inline oxygenation/carbonation unit, but at one end have an IR emitter, adjusted to the CO2 sensitive range, and at the other a simple diode...Due to Brownian Motion, there'll always be some variance which you use as your baseline measurement, when significant more photons are lost, it would indicate a greater mass (owing to the motion of a leak).

This is the sort of thing I would have tried to build before 2014, but I simply no longer hace the knowledge or skills...not to mention; my sense of proportion.

Maybe one of you sound scientific-minded could work with it, or at least tell me that I'm way off track.

Similar threads

- Replies

- 32

- Views

- 783