somekindofnick

Active Member

I compared two immersion chillers--a stainless steel 50ft 1/2" coil and a custom Hydra from JaDeD. I completed two tests--10 gallons of water and 5 gallons of wort.

The Hydra was the best performer, especially when the wort level was lower in the kettle (i.e. 5 gallon batches). The stainless did not perform as well as the Hydra because the coils were too tall and extended above the fluid level.

Furthermore, I don't mean to understate the craftsmanship and creativity that went into the Hydra. The Hydra splits the water flow into three separate coils before returning to one outlet. This is like using three immersion chillers at once!

Summary results:

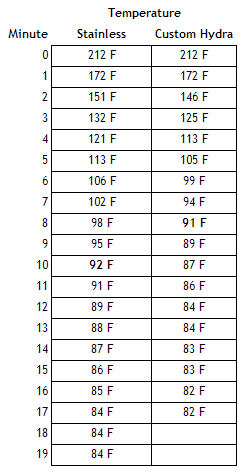

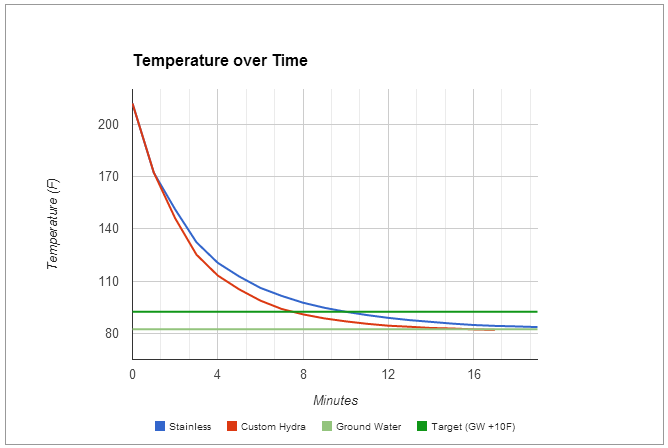

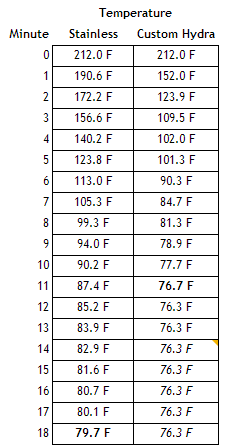

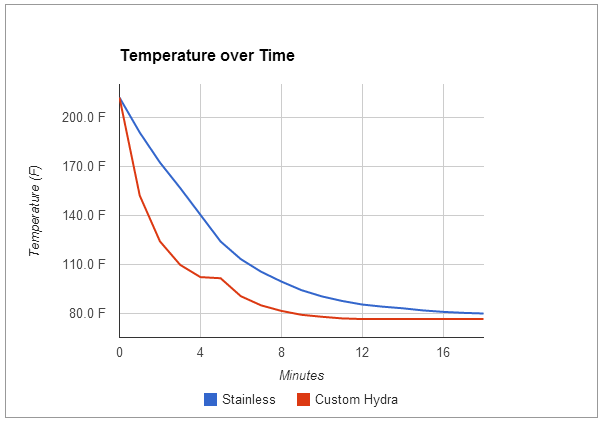

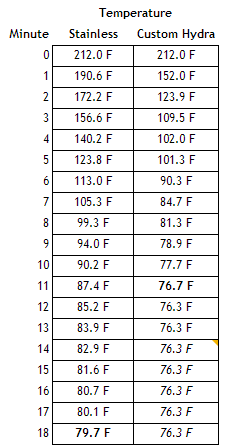

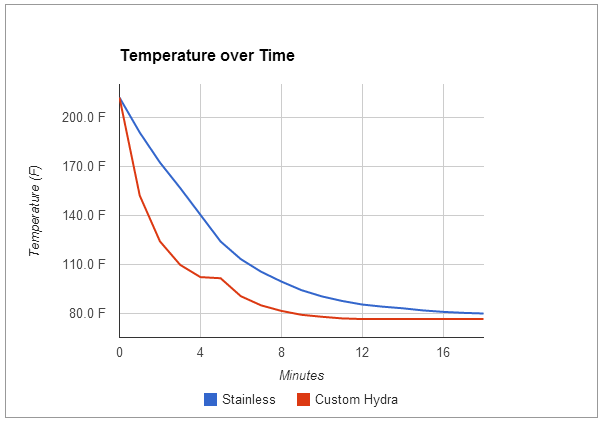

10 gallons of water:

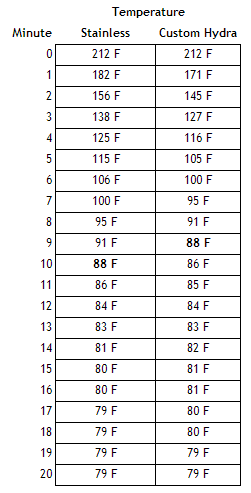

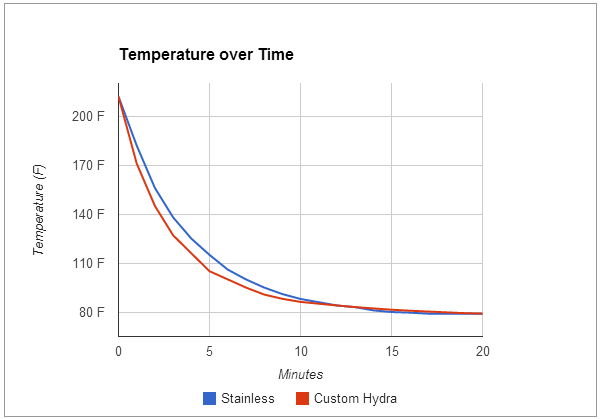

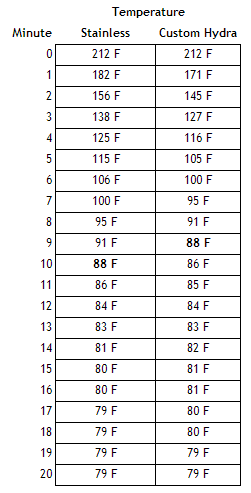

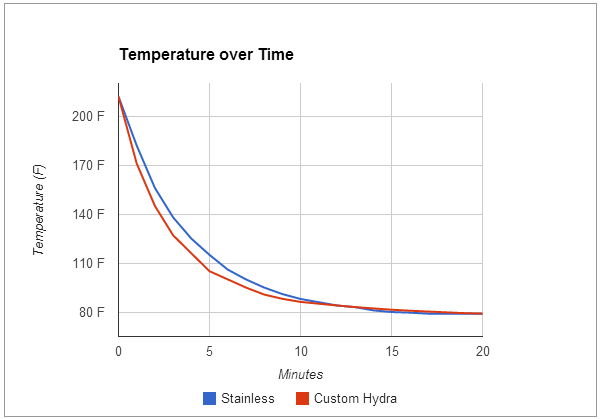

5 gallons of wort:

I documented my results here with detailed data sheets: http://e30dohc.com/wordpress/?p=13

I spoke to JaDeD about the results and they were not satisfied with the chilling time. In addition to pointing out a couple of issues/anomalies (i.e. Hydra chilling wort to cooler than ground water temp, hose length longer than 6ft), JaDeD felt that the Hydra should be chilling twice as fast as my results. As such, I plan to run additional tests in the coming weeks. More to come!

The Hydra was the best performer, especially when the wort level was lower in the kettle (i.e. 5 gallon batches). The stainless did not perform as well as the Hydra because the coils were too tall and extended above the fluid level.

Furthermore, I don't mean to understate the craftsmanship and creativity that went into the Hydra. The Hydra splits the water flow into three separate coils before returning to one outlet. This is like using three immersion chillers at once!

Summary results:

10 gallons of water:

5 gallons of wort:

I documented my results here with detailed data sheets: http://e30dohc.com/wordpress/?p=13

I spoke to JaDeD about the results and they were not satisfied with the chilling time. In addition to pointing out a couple of issues/anomalies (i.e. Hydra chilling wort to cooler than ground water temp, hose length longer than 6ft), JaDeD felt that the Hydra should be chilling twice as fast as my results. As such, I plan to run additional tests in the coming weeks. More to come!