nudarkshadowl

Well-Known Member

- Joined

- Apr 4, 2014

- Messages

- 51

- Reaction score

- 26

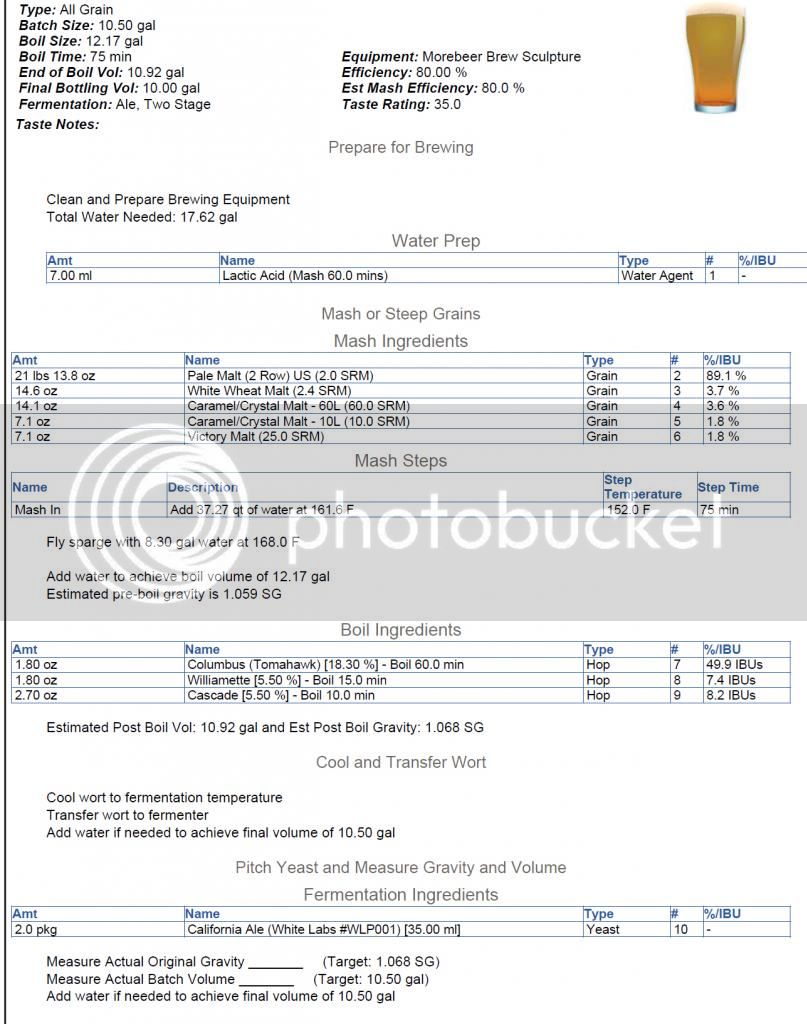

Well, I finally ordered my dream brew rig! A 10 Gallon Morebeer Single Teir Digital Brew Sculpture. This thing is going to be a beast, and is actually the exact system that commercial breweries such as Stone, Pike, etc. use for their pilot system. Can not wait to get this thing going. My first all grain batch will be on the new system, so im going to have to do some research over the next few weeks, but I am so excited! Also, I love the DIY aspect of this hobby, and have actually tackled quite a few projects already but I really wanted to get something that is a proven system right from the start, rather than building my own. I know I could have built something similar for slightly cheaper, but I really don't have the time, necessary welding skills, or honestly; the patience to build something that would be comparable to this unit.

I'm sure most know, but for those that don't, it's basically a fully automated system with auto sparge features, recirculation capability, temp controlled burners, water level float switches, etc.

Full list of components:

Stainless Steel Maximizers and Diverter

Analog Thermometers

Two High Flow March Pumps

Stainless Steel Sparge Arm Assembly

Stainless Steel Frame

Control Panel

Mash Tun and Hot Liquor Tank Float Switches

Mash Tun and Hot Liquor Tank Digital Temperature Control

Propane Gas System (Compatible With Low and High Pressure Propane)

Automated Hot Liquor Tank Burner

Convoluted Heat Exchanger

Boil Kettle Whirlpool Arm

All Necessary Tubing

CAN NOT WAIT! :rockin:

I'm sure most know, but for those that don't, it's basically a fully automated system with auto sparge features, recirculation capability, temp controlled burners, water level float switches, etc.

Full list of components:

Stainless Steel Maximizers and Diverter

Analog Thermometers

Two High Flow March Pumps

Stainless Steel Sparge Arm Assembly

Stainless Steel Frame

Control Panel

Mash Tun and Hot Liquor Tank Float Switches

Mash Tun and Hot Liquor Tank Digital Temperature Control

Propane Gas System (Compatible With Low and High Pressure Propane)

Automated Hot Liquor Tank Burner

Convoluted Heat Exchanger

Boil Kettle Whirlpool Arm

All Necessary Tubing

CAN NOT WAIT! :rockin: