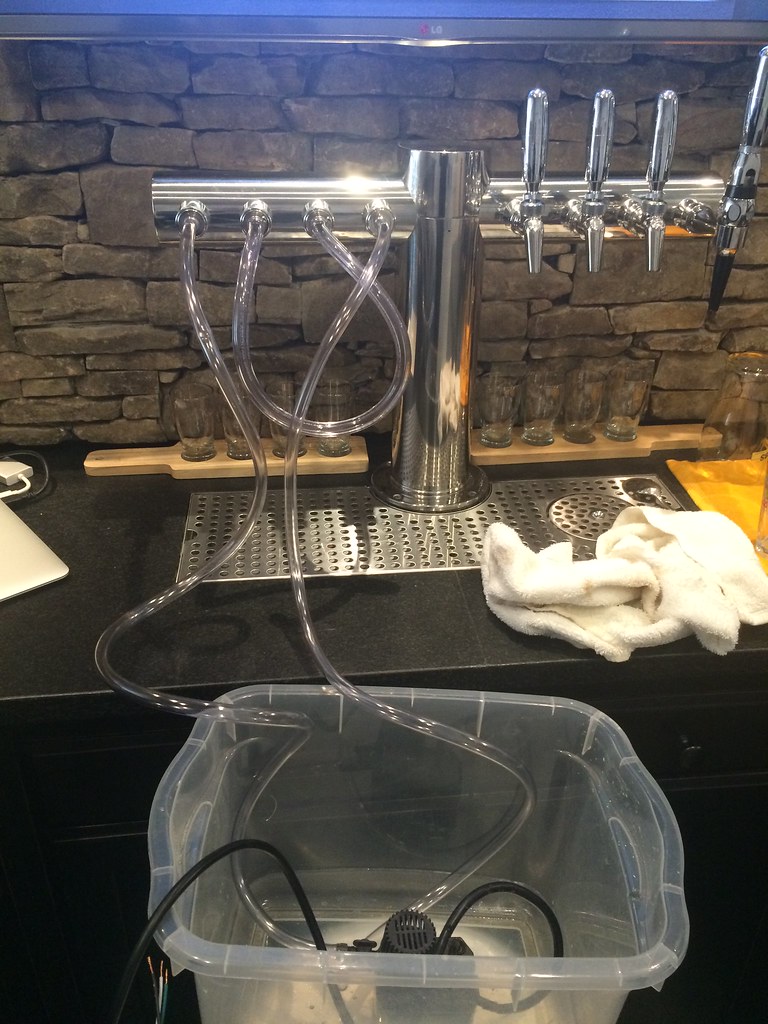

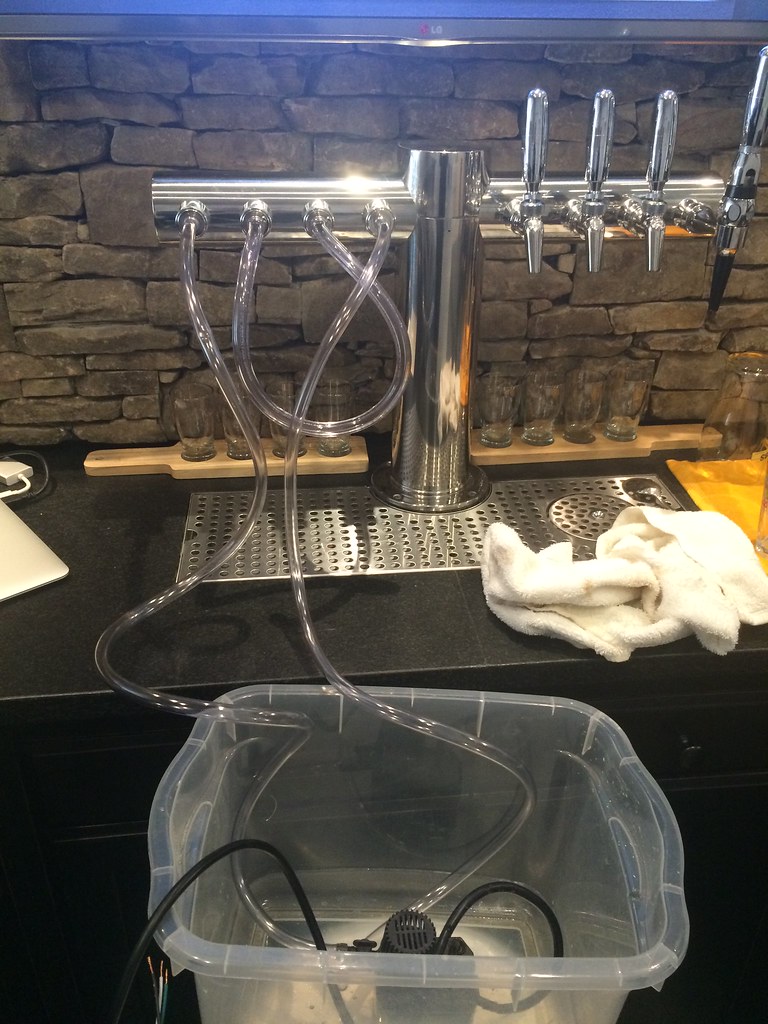

I have been researching the easiest way to clean my 8 tap T-Bar Micromatic tap system and have found the method below to be very effective. I ordered 2 beer cleaner faucet jumper hoses and hooked them to an aquarium pump in a bucket to clean 4 taps at the same time. I run PBW through for 20 minutes, star san through for 20 minutes and then re-hook my beer lines to the system. I will be cleaning the taps every two months in this way. I picked up two ball lock couplers to create a loop in the kegerator.

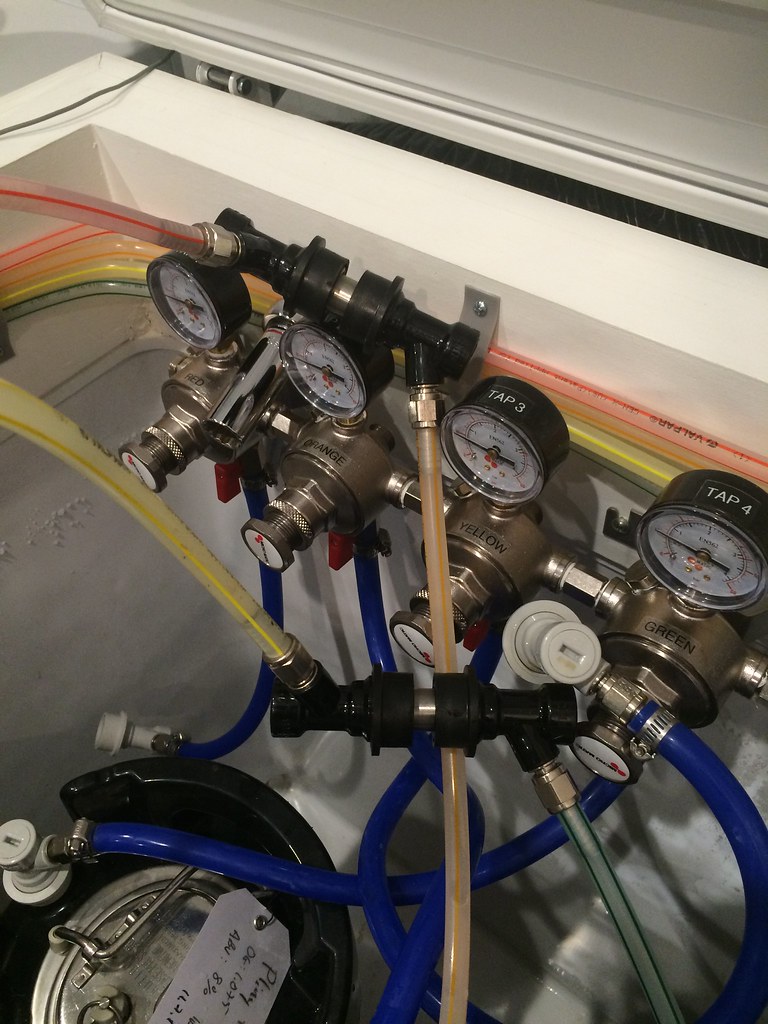

I send the cleaner in through tap 1 which is coupled with beer lines 1 and 2 in the kegerator, out through tap 2 through the jumper line to tap 3, coupled in the kegerator with lines 3 and 4 and out tap 4 back into the bucket. I do the same setup with taps 5-8.

Here are some pics:

IMG_0473 by jonymac, on Flickr

IMG_0473 by jonymac, on Flickr

Pump to Tap 1, jumper between Taps 2-3 and output back to bucket from Tap 4

IMG_0474 by jonymac, on Flickr

IMG_0474 by jonymac, on Flickr

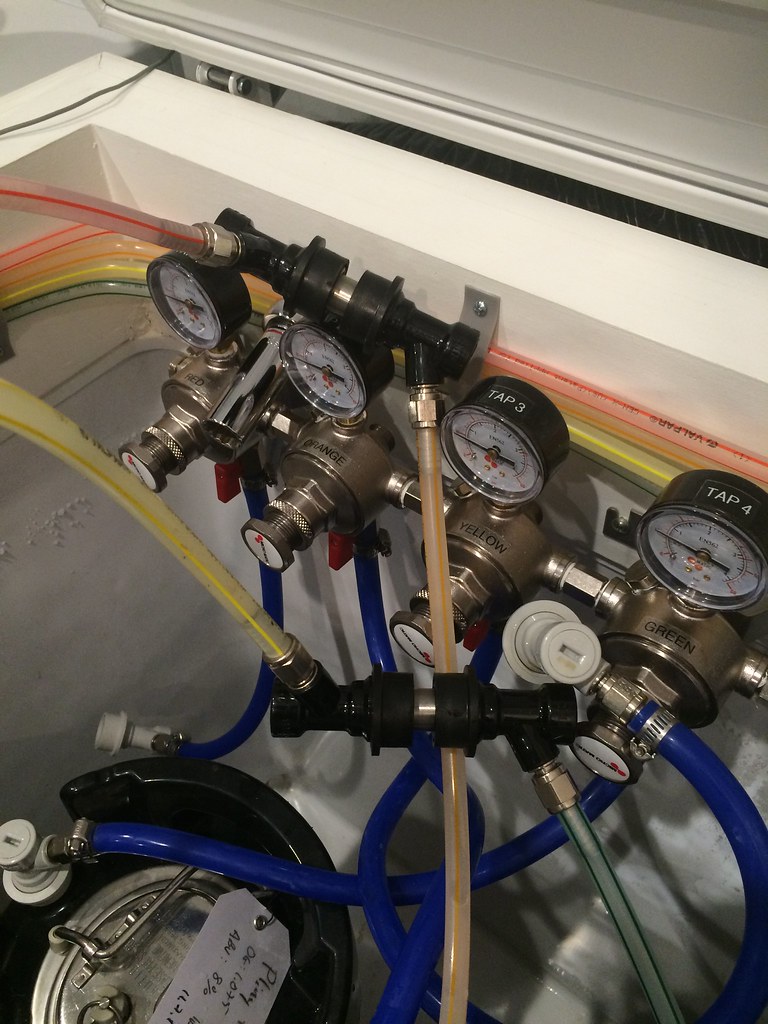

Ball lock couplers connected between beer lines 1&2 and 3&4

IMG_0478 by jonymac, on Flickr

IMG_0478 by jonymac, on Flickr

Ball lock coupler

IMG_0479 by jonymac, on Flickr

IMG_0479 by jonymac, on Flickr

Tap jumper hose

I send the cleaner in through tap 1 which is coupled with beer lines 1 and 2 in the kegerator, out through tap 2 through the jumper line to tap 3, coupled in the kegerator with lines 3 and 4 and out tap 4 back into the bucket. I do the same setup with taps 5-8.

Here are some pics:

IMG_0473 by jonymac, on Flickr

IMG_0473 by jonymac, on FlickrPump to Tap 1, jumper between Taps 2-3 and output back to bucket from Tap 4

IMG_0474 by jonymac, on Flickr

IMG_0474 by jonymac, on FlickrBall lock couplers connected between beer lines 1&2 and 3&4

IMG_0478 by jonymac, on Flickr

IMG_0478 by jonymac, on FlickrBall lock coupler

IMG_0479 by jonymac, on Flickr

IMG_0479 by jonymac, on FlickrTap jumper hose