I found a good discussion of potential causes of LCD scrambling here:

http://hackaday.com/2014/02/27/fail-of-the-week-reset-issues-with-595-and-hd44780/

http://hackaday.com/2014/02/27/fail-of-the-week-reset-issues-with-595-and-hd44780/

Read the whole thread, and along with the specific issue (programmed reset failing) nothing there really applies to our noise problem...

Cheers!

Since you haven't finished building yours yet you might find you don't suffer from the problem when it's done.How about using some wire that's shielded to the LCD?

Shielding is unlikely to be the answer to voltage/gnd sag - what I think is really going on.

I'd be interested in knowing if the folks having LCD scrambles are powering their Uno's via USB versus a dedicated 9-12VDC wall wart...

Cheers!

Yet Another Waste of Time...

I haven't put together a write up yet on the board, but you can use this link for a list of the parts.

https://www.mouser.com/ProjectManag...jectGUID=58a4b209-8794-4e83-abe7-86ceca4ae1f4

So it turns out that red soldermask is more photogenic than purple...

Thanks to @Bigdaddyale for the pcb from his batch of boards.

Populated the board, plugged it in, tweaked the pot and it's up and running.

Easy peasy...

Cheers!

There is something screwy with that link.I had 18 different parts when I ordered.This link still working for folks? I only see five parts on the list...

There is something screwy with that link.I had 18 different parts when I ordered.

Mfr. # Manufacturer Desc. Customer Part # Order Qty.Thought so. When I looked at it a few weeks ago it was a full list. I can make up my own order--unless you have a saved list somewhere...

here is a pdfMfr. # Manufacturer Desc. Customer Part # Order Qty.

85 Adafruit Adafruit Accessories Shield stacking headers for Arduino (R3 Compatible) Adafruit 1

SN74HC595N Texas Instruments Counter Shift Registers Tri-State 8-Bit U1 1

BSS84 Fairchild Semiconductor MOSFET SOT-23 P-CH ENHANCE U2 1

110-13-316-41-001000 Mill-Max IC & Component Sockets 16P GLD PIN GLD CONT Socket 1

450-4760 Eagle Plastic Devices Knobs & Dials SOFT TOUCH D SHAFT Knob 1

ACZ11BR1E-15FD1-20C CUI Inc. Encoders Encoders Rotary Encoder 1

22-28-4183 Molex Headers & Wire Housings 2.54MM BREAKAWAY Vertical 18 CKT Gold Headers 2

1N4001 Fairchild Semiconductor Rectifiers Vr/50V Io/1A T/R D1, D2 2

CF1/2CT52R200J KOA Speer Carbon Film Resistors - Through Hole 20 ohm 5% R10 1

MF1/4LCT52R221J KOA Speer Metal Film Resistors - Through Hole 1/4 WATT 220 OHM 5% R9, R11 2

MF1/4LCT52R202J KOA Speer Metal Film Resistors - Through Hole 1/4 WATT 2K OHM 5% R8 1

CF1/4CT52R102J KOA Speer Carbon Film Resistors - Through Hole 1K ohm 5% R7 1

MF1/4LCT52R472J KOA Speer Metal Film Resistors - Through Hole 1/4 WATT 4.7K OHM 5% R6 1

CF1/4CT52R103J KOA Speer Carbon Film Resistors - Through Hole 10K ohm 5% R3 - R5 3

299-10K-RC Xicon Carbon Film Resistors - Through Hole 10Kohms 5% R2 1

3296Y-1-103LF Bourns Trimmer Resistors - Through Hole 3/8" 10Kohms Sealed Vertical Adjust R1 1

SR205E105MAR AVX Multilayer Ceramic Capacitors MLCC - Leaded 50volts 1.0uF 20% C8 1

1C10Z5U104M050B Vishay Multilayer Ceramic Capacitors MLCC - Leaded 0.1uF 50volts Z5U 20% 2.5mm L/S C1 - C7 7

You don't have the P-FET on the board, and I don't see a modification either. Are you running the 5V to the diodes for the backlight?

This link still working for folks? I only see five parts on the list...

Shielding is unlikely to be the answer to voltage/gnd sag - what I think is really going on.

I'd be interested in knowing if the folks having LCD scrambles are powering their Uno's via USB versus a dedicated 9-12VDC wall wart...

Cheers!

I found some 3A power supplies so I'm going to try those if I have an issue and see if they help.

What is the reason to use Bluetooth attached to shield? And the Rotary encoder is used for what? About resistors, what is the best kind of? metalic, ceramic....? About resistors power, the value shown (ex 1/4W) this is the minimum power desired?

- to enable wireless Arduino agents

- to allow programming at the Arduino

- the resistor type is non critical, use whatever is easily available

- 1/4 watt is the most commonly available axial lead resistor

Cheers!

If you use the shield that I created, you have to go with the BSS84 because the shield has the surface mount pins already built in. If you use a protoshield design based on the original project created by day_trippr, you can use either the BSS84 or the PNP. The advantage of the PNP is that it is easier to solder because it has a through-hole design.

You could also modify the design of the board before you send it off to be printed to accommodate the PNP instead of the PFET.

@daytrippr, thanks for you fast reply.

About "to enable wireless Arduino agents" is used to connect Arduino to RPi/PC? And about "to allow programming at the Arduino" Could we programming Arduino w/o web interface? I didn´t undestand well how to for both questions, could you explain a little bit more?

Thanks again,

Fabiano

@CadiBrewer, is it possible use your board without BSS84? What this component do? I am having difficult to find it in Brazil. Is there other name/reference for this component?

Thanks,

Fabiano

Yes, it was solved on the hackaday link. It's caused by the lcd powering up later than the microcontroller. One commenter solved it by powering the lcd from a transistor activated by the microcontroller.

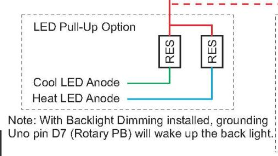

The bss84 p-channel mosfet deals with the auto shut off (dimming) of the LCD screen. Yes, you can use the board without the component if you don't mind having the screen always on. You would just solder a small wire between two of the three pads on the board. You want to tie the drain and source pads together.

If you look at the three pads as a triangle, the drain pad is the top of the triangle. The source pad is the bottom right leg of the triangle. Solder a small piece of wire between the two pads. You can use a cut off piece from one of your resistors.

.

Did it help?

Has anyone worked out what was causing the scrambling issue?

About LED, those have 2 poles. One pole should be linked to anode after resistor and the other should be linked to GND?

Thanks.

@CadiBrewer, thanks for explanation. From the file attachad (P-fet), I have to link D (3) with S (2)? May I ommit also PNP transistor? PNP transistor do the same of P-fet (shut off LCD)?

Thanks.

Yes, it was solved on the hackaday link. It's caused by the lcd powering up later than the microcontroller. One commenter solved it by powering the lcd from a transistor activated by the microcontroller.

Enter your email address to join: