[edited 01/16/2014 - added recommended wire type/size)

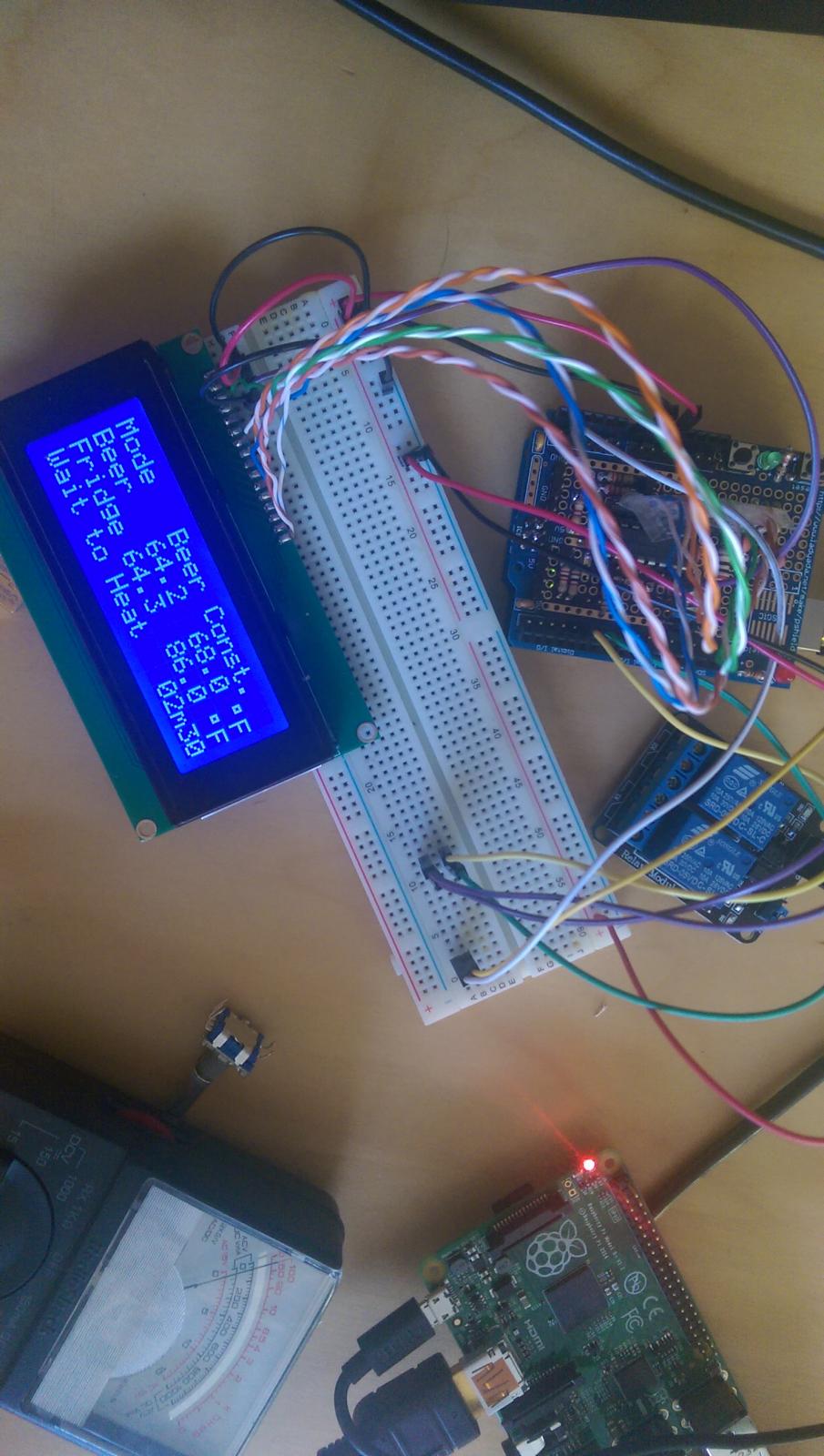

The second minion is up and running, so I had time to complete the protoshield build documentation.

The basic scheme supports the One-Wire bus and the LCD display.

Refer to the original post in this thread for links to the larger pieces.

There are also these support options:

- Bluetooth/Serial Module

- rotary encoder switch

- cool/heat panel LEDs

Parts: Starting with what's included in the Arduino Protoshield V6 (latest/greatest) the additional parts required for the basic scheme are:

- 20x4 white-on-blue parallel-entry display

- 74HC595D

- 10K 3-lead trim pot

- (2) IN4007 diodes

- 20 to 30 ohm resistor 1/2W

- 4.7K resistor 1/4W

- I recommend using 24-26 gauge solid, insulated wire

- optional but recommended: 16 pin IC socket

- optional but recommended: extra .1 UF >10V ceramic capacitors (2 or more)

- optional: extra header pins

Add for Bluetooth/Serial Module:

- 1K resistor 1/4W

- 2K resistor 1/4W

Add for Rotary Encoder:

- (3) .1UF >10V ceramic capacitors

- (3) 10K resistors 1/4W

Add for panel LED support:

- (2) 220 resistors 1/4W

Also, I've included a schematic of the AC switching scheme I'm using. This provides independent On/Off/Auto control for the Cool and Heat AC outlets. This uses a pair of

20A rated DPDT On-Off-On switches and a pair of LEDs along with the Sainsmart dual relay card. All of that is optional.

Building the base Protoshield: There is a tutorial for assembling the Arduino Protoshield

here. Unfortunately it is for an earlier revision PC board, but almost all of the instructions still apply.

The kit comes with the parts shown in the first picture below.

I used all parts but the two 1x5 headers and one of the 1x6 headers.

Caution: Note which side is "UP" before starting.

The only part that is installed from the BOTTOM side of the board is the 2x3 stacking header (shown at the left edge in the second picture).

Completing the Build:

I prefer not to use Dupont wires with male ends as they need more air space above the board and are intrinsically fragile. I've done this layout so all wire connections use female Duponts.

The kit comes with a strip of 36 header pins which is enough - if you install them where they are needed. If you have extra header pins on hand you can go nuts like I did, but if you're stuck with just the 36 pins in the kit, I've highlighted the

32 pins that need to be present. These pins match up with the jumper wire connection points in the diagram at the bottom of this post.

The IC orientation isn't optimal wrt the Protoshield etch (IC power and ground pins are on the "wrong" sides of the two bus strips), but was to keep the switching inputs to the IC as short as possible as HC series logic doesn't take well to input ringing.

So there it is. Hopefully there's enough here to successfully construct a protoshield, but feel free to post any questions/issues/objections/suggestions here...

Cheers!