How are you powering the Uno?

From the USB side, or using a 9-12V wall wart?

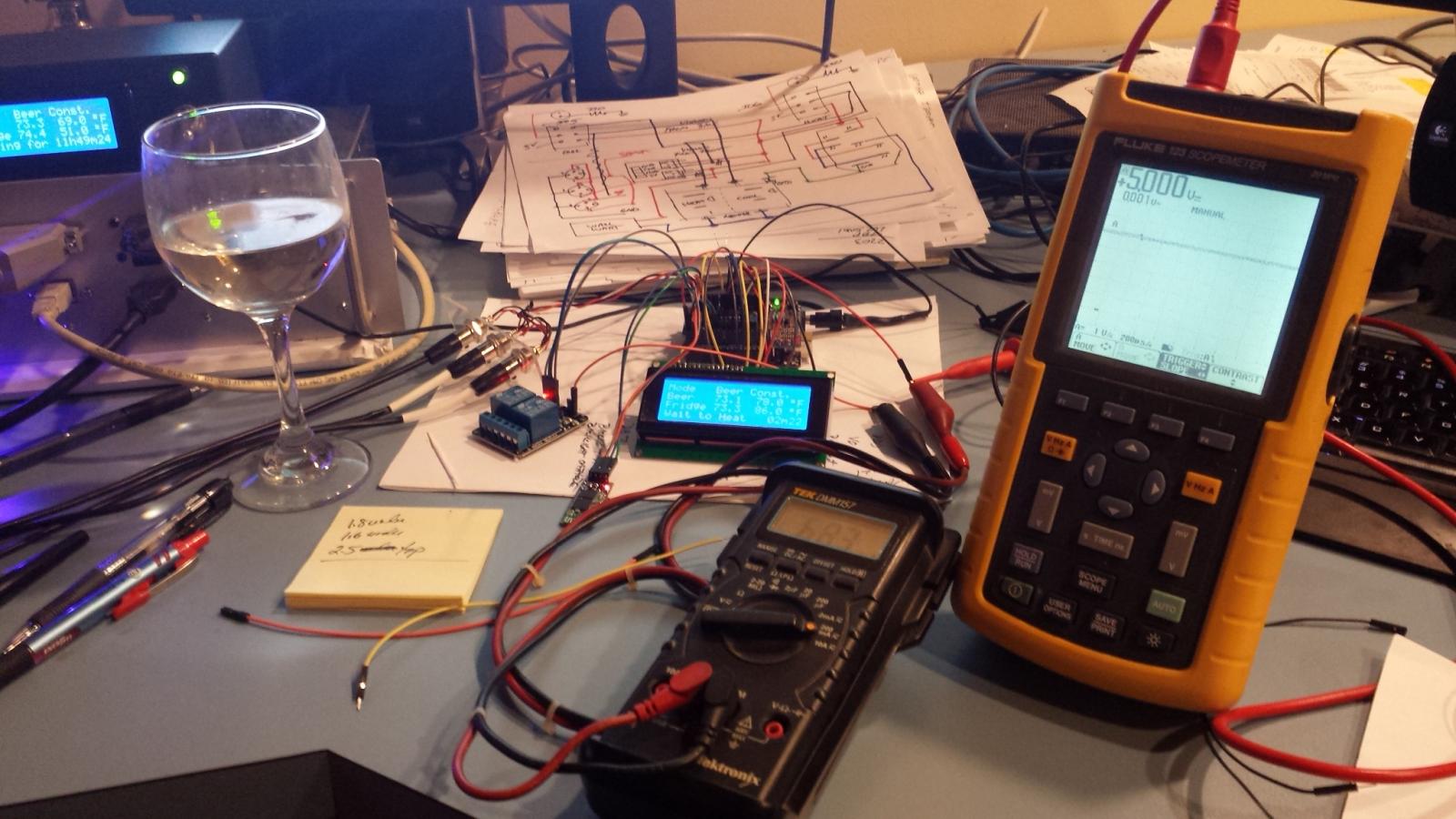

Cheers!

From the USB side, or using a 9-12V wall wart?

Cheers!

Yes it's that one,

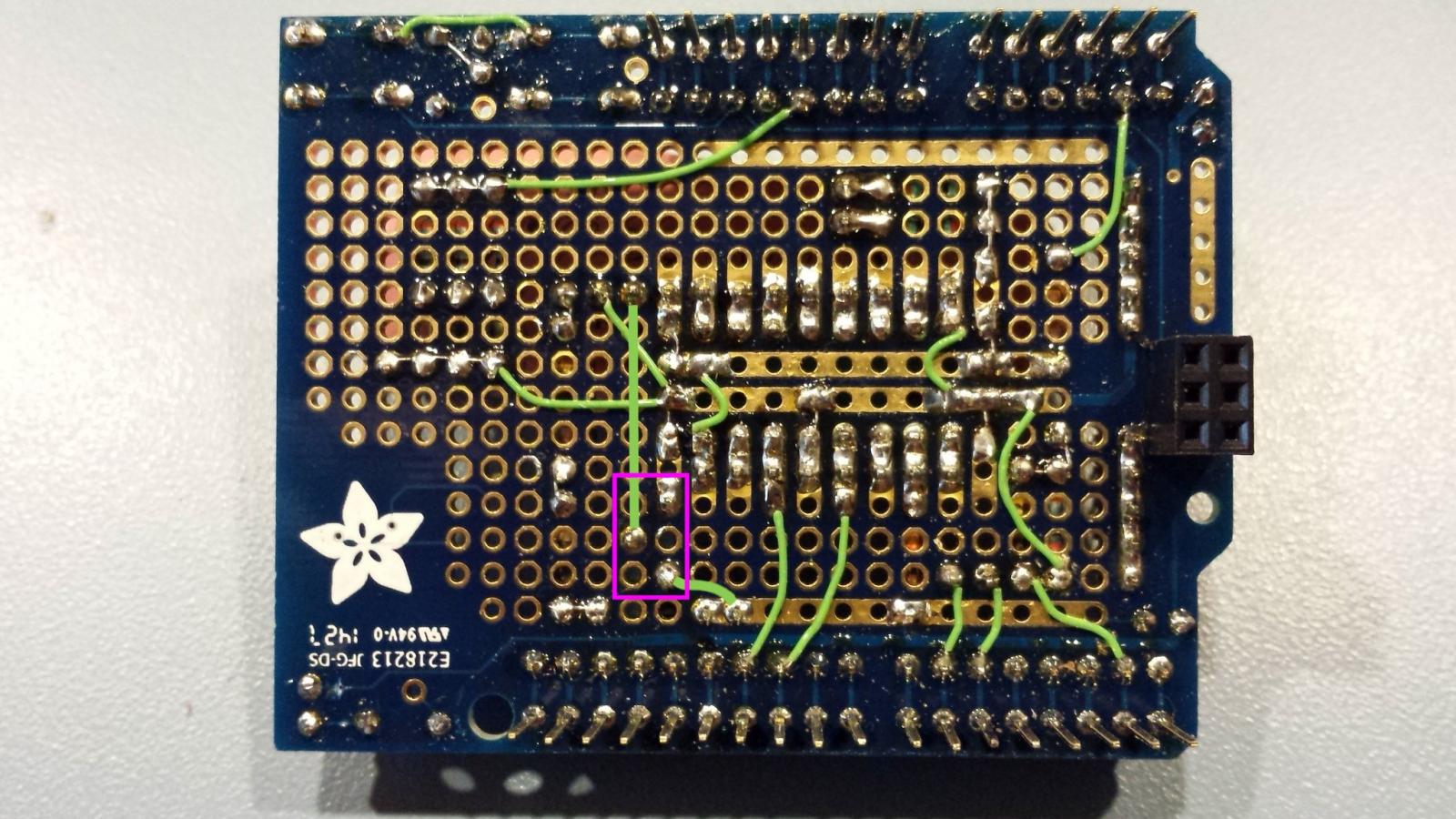

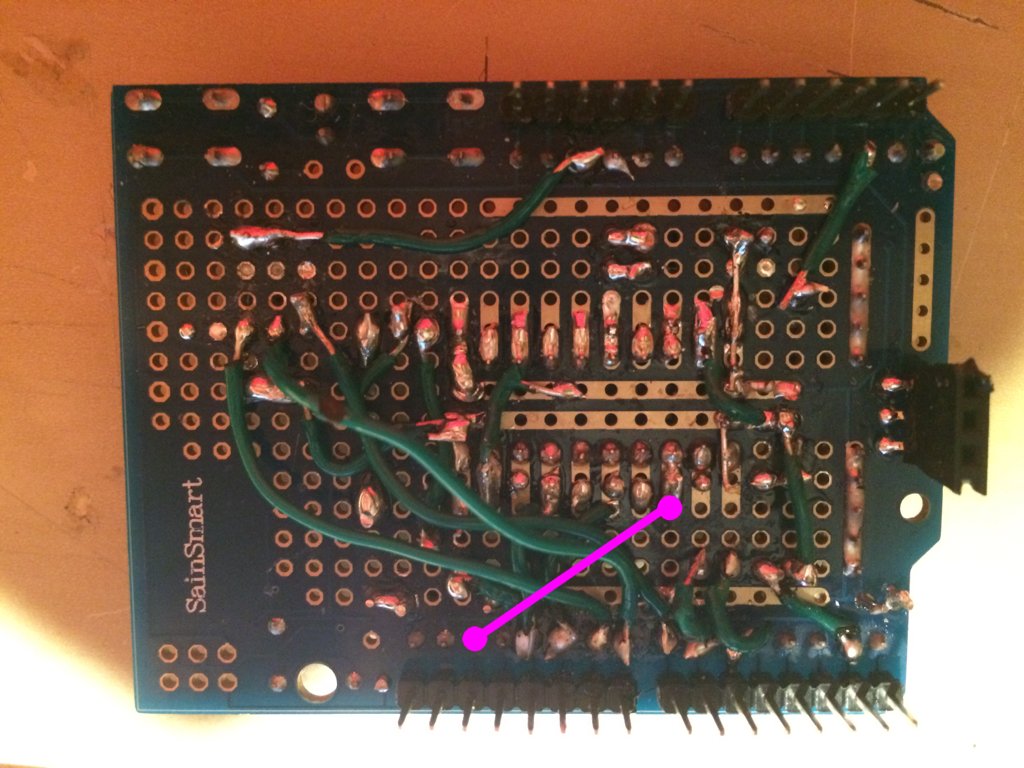

My uno is a Sainsmart uno rather than an arduino uno

I'll have to check but I think I have a spare rotary encoder or two. I used these - and they work.

http://www.ebay.com/itm/251453678924?_trksid=p2059210.m2749.l2649&ssPageName=STRK:MEBIDX:IT

I'll try and take some photos of my setup later today, and add them.

The only thing i've noticed is you seem to have a 5th wire coming out of the back of your relay, but i'm guessing that is purely to test the rather than having a function for the Brewpi?

[...]Having soldered most of it together am i right that the 10k pot isn't soldered in a line, I.e first pin starts below the extra capacitor middle pin one row to the right and last in under capacitor again?[...]

@day_trippr Just noticed you post on the other thread re v.5 shield.

on your diagram that you only use the header to connect the power and ground to rails so figured I didn't need a full length pin so with a couple of bend in the pin I think it'll reach the arduino and still have enough metal to connect to the rails.

I'm not planning to stack anything on top of that.

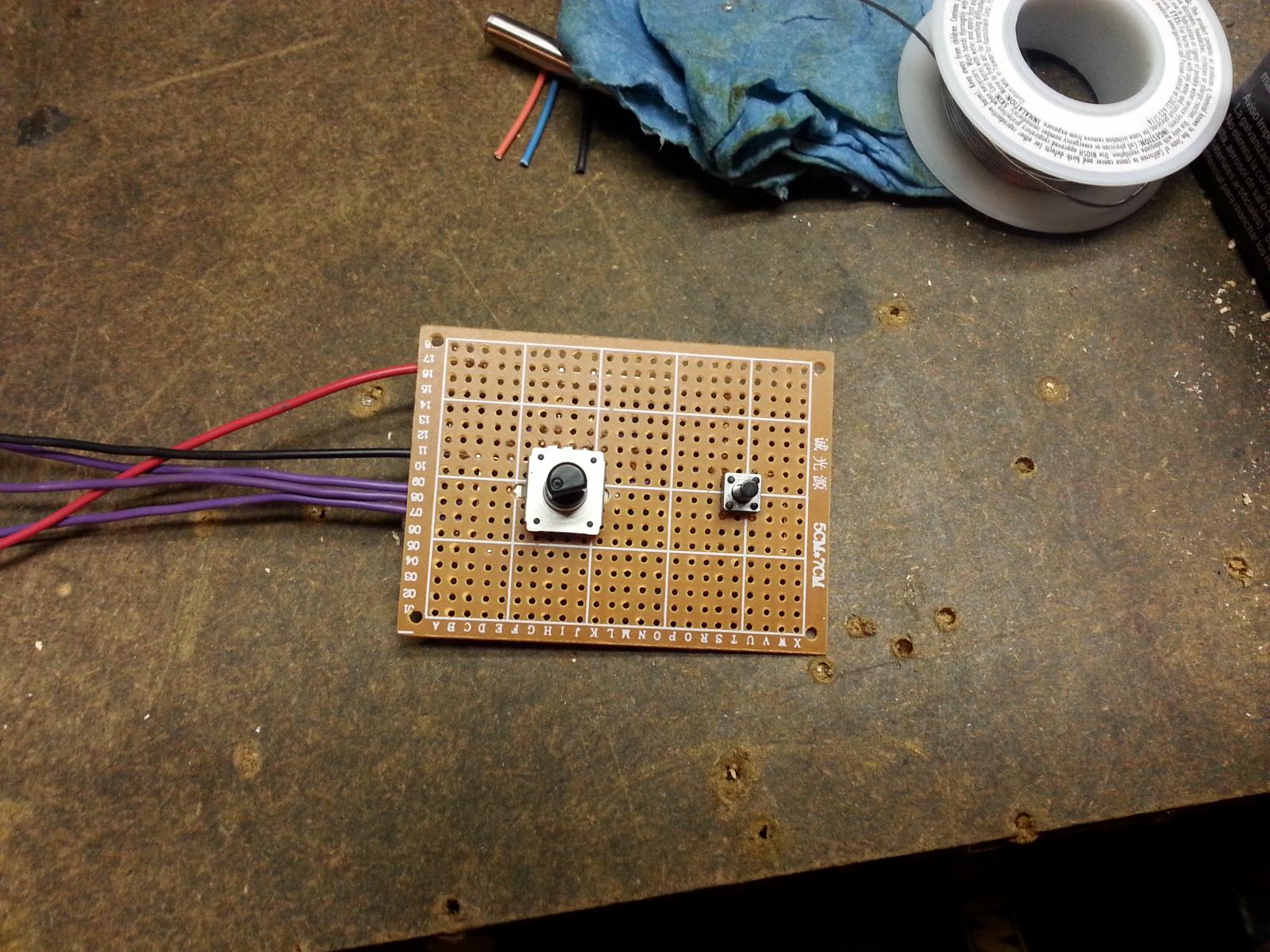

Do those have a pushbutton?

I'm still waiting on mine.

S l o w boat from China this time.

I hate it when that happens...

Cheers!

Enter your email address to join: