trip2hard

Well-Known Member

Looking great!! Should have my keg washer done this week. Its at the welders

trip2hard said:Looking great!! Should have my keg washer done this week. Its at the welders

fastev said:Good day, and I didn't get busted for staying out too late!

Looks great Marc, glad to see the coolbot working. I'd imagine once the ac units are trimmed out the temp will really plummet in the cold room! We'll have to put bomber hinges on all the doors to keep them closed.

Have a great trip, I'm going to try to have the panel ready for Thursday...

Marc, next time im down in Santa Clara, I need to check this out. Who did your welding? I have a few fittings that are beyond my skill level.

Dukeman9988 said:I'm confused. Are you going pro or not? You keep hinting but I haven't seen a confirmation. Lol

Yes and no.

Dukeman9988 said:Ahhhhhh. That really clarified things

The best part is that I won't need to do it in the driveway and entertain another million breaking bad cracks from the passersby ; )

jaredr said:so true, pretty sure my neighbors think i'm "cooking" in my driveway.

awesome work, been enjoying following this thread.

Carlscan26 said:Can you clean multiple kettles at once?

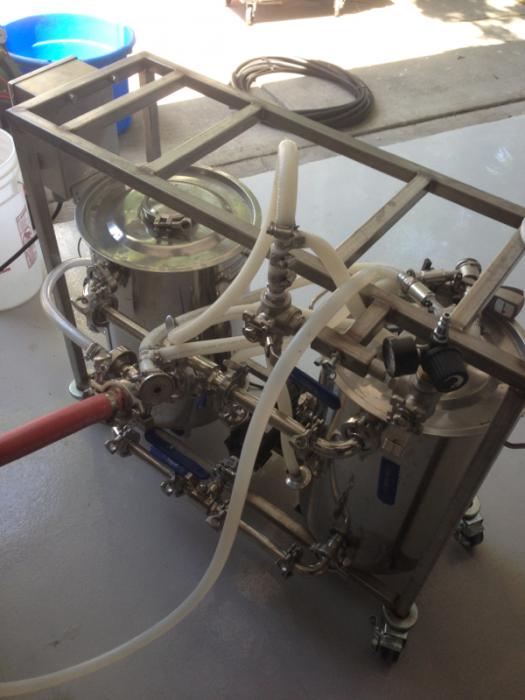

marcb said:Probably not unless I get bigger reservoirs. The 10 gallon reservoir is a little light to pump through the sprayball at volume. The pump does a great job though and my little keg washer kept the water at 185 (about 15 gallons total)

marcb said:Cold room sitting comfortably at 35 degrees!

Chamuco said:Yeaaaaaaah buddy!

marcb said:Check it!

Couldn't resist, had to uncrate a fermenter. Glacier tanks is awesome. Fantastic quality, super customer service, only downside is the wait for products. I'm very pleased with this purchase.

Jaybird said:Very NICE!!!!! so what are you going to use for a heat exchanger and cooling water? Are you going to do a hot water recovery tank to reclaim the hot water from the heat exchanger?

Nice looking build Marc

Cheers

Jay

Panel is in, should be heated up here pretty quick!

barryfine said:I've been loving this build, but just one suggestion. I also use an on demand hot water heater and found that silicone tubing connected directly to the water heater was a bad idea. If you open the valve on the wall without opening the valve on the tank you are filling, the silicone will balloon out and eventually pop off the fitting. To address this, I substituted stainless hose that is typically used to hook up a washing machine.

Now I'll go back to drooling over your awesome setup. Cheers!

Hi Barry! The tubing is actually reinforced silicone tubing and runs about $10 per foot! After turning regular 1/2" silicone tubing into a water weeny I went down this route. I've been having a hard time finding any tubing that is good enough (food safe and high temp) with a 1" diameter that isn't 20-30$ per foot! This tubing is good for up to 200 psi and is food safe. I think I bought it from McMaster.... I also used the same stuff on my keg washer.

Can't wait to see how the automation is set up! Great build.

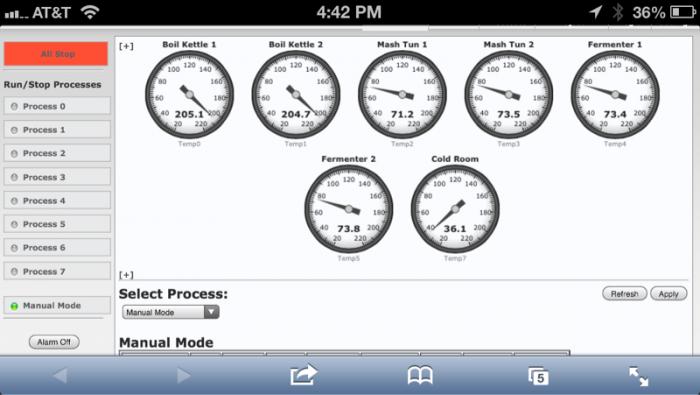

marcb said:Thanks! This will be BCS controlled (at least the mash/boil kettles) will be. Looks like I've got a bad contactor after two days of troubleshooting : (

Onward and upward, still not boiling water yet......

marcb said:Still troubleshooting the ghosts in the panel, now I'm off to 5 countries for work - on hold for another week : (

I'm sure in another month or so I'm going to look back at my impatience now and laugh but dammit, right now it ain't so funny! I need to brew!

Carlscan26 said:What is that thing to the left of the conicals?

Enter your email address to join: