Mike_McBrew

Active Member

- Joined

- Jun 7, 2015

- Messages

- 36

- Reaction score

- 5

Hello all,

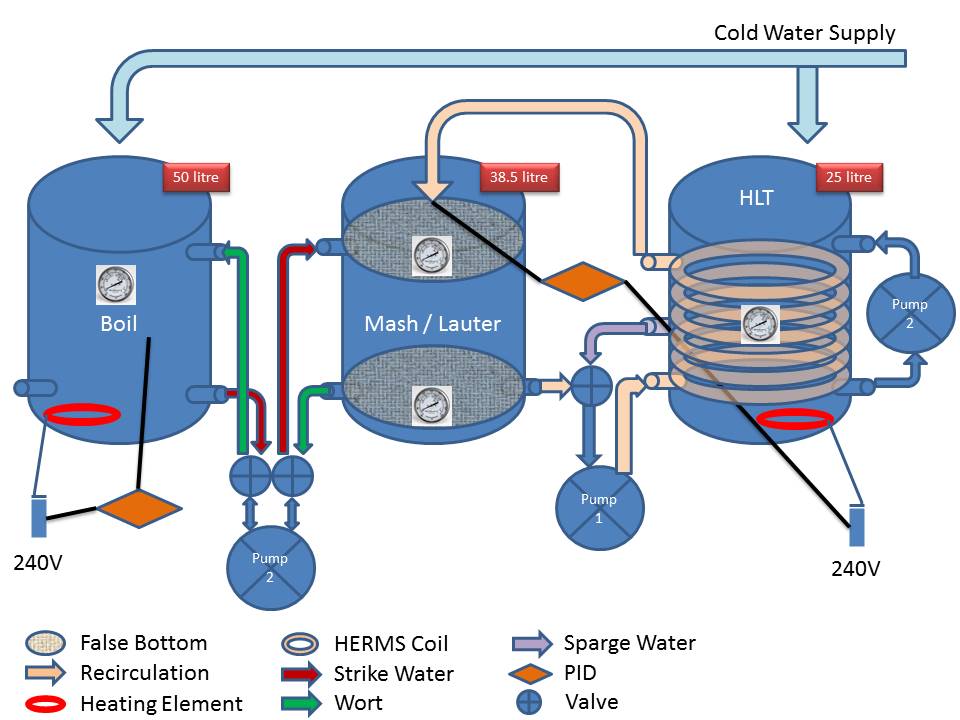

I am hoping to take advantage of your experience in designing a HERMS. I am in the middle of pricing the system and wanted to know if there are any glaring errors. I realise that every one will have their own preferences and I hope to ask some more specific questions later but in the first instance it's a question about major errors and omissions.

In order of events the idea would be to :

1. Heat the strike water in the boil kettle

2. Heat the water in the HLT to the temperature for recirculating the wort

3. Pump the strike water into the Mash tun

4. Add the grist

5. Start recirculating the wort through the HLT

6a. If the HLT water is at sparge temp. at the end of the mash then use that to supply the sparge water, pushing it through the coil so as to simplify the piping

6b. If the HLT water is not at the sparge temperature then heat the sparge water in the boil kettle and supply the mash tun directly

7. Pump the wort into the boil kettle

8. Add hops and boil

9. Cool the boiled liquid via a cooling coil (not shown)

10. Pump into the fermenter

The HLT is sized smaller so as to minimise the duration of temperature changes in multi step mashes.

The boil kettle is sized larger so as to avoid splashing / foaming over.

I have a false bottom on top of the mash tun as ell as the bottom to spread the recirculating wort across the entire surface. I have also seen people use the recirculation to cause (deliberately) rotation but I haven't understood the advantages and disadvantages yet - I'll ask this question in a separate thread in a different forum.

I would intend to use two pumps although if the piping is too long to recirculate (to maintain a consistent temperature) the water in the HLT (without too much cooling during its travels) then I'd add a third pump in order to shorten to circuit.

I'd intend that all entry / exit to the vessels would be tapped. The valves would be three way, one exit and two entries with a tap to switch between the entries.

Thanks in advance for all and any help.

Mike

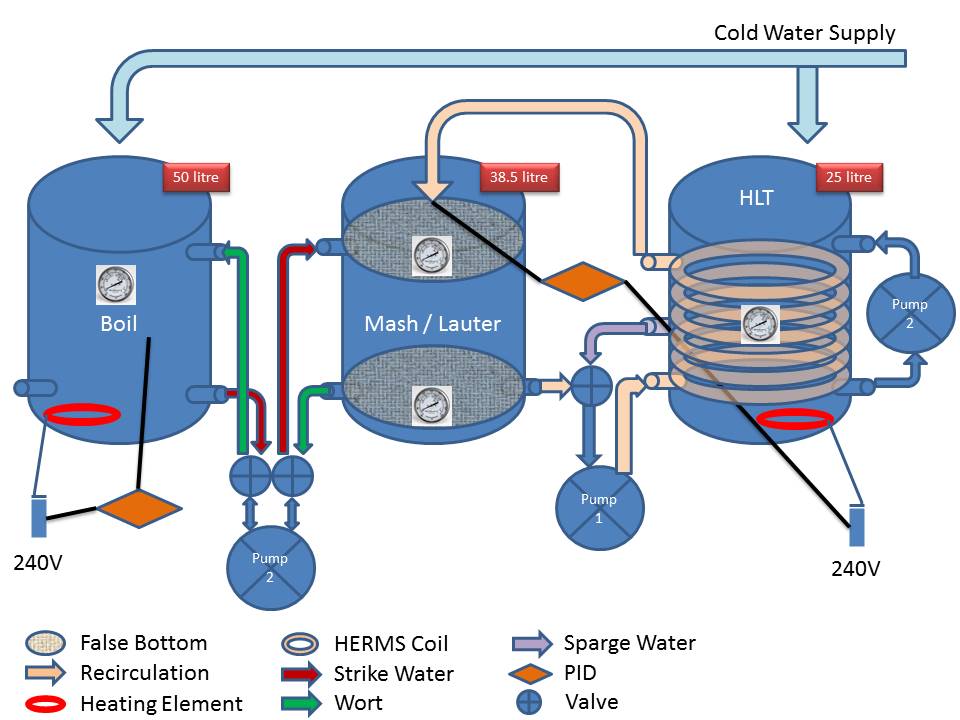

I am hoping to take advantage of your experience in designing a HERMS. I am in the middle of pricing the system and wanted to know if there are any glaring errors. I realise that every one will have their own preferences and I hope to ask some more specific questions later but in the first instance it's a question about major errors and omissions.

In order of events the idea would be to :

1. Heat the strike water in the boil kettle

2. Heat the water in the HLT to the temperature for recirculating the wort

3. Pump the strike water into the Mash tun

4. Add the grist

5. Start recirculating the wort through the HLT

6a. If the HLT water is at sparge temp. at the end of the mash then use that to supply the sparge water, pushing it through the coil so as to simplify the piping

6b. If the HLT water is not at the sparge temperature then heat the sparge water in the boil kettle and supply the mash tun directly

7. Pump the wort into the boil kettle

8. Add hops and boil

9. Cool the boiled liquid via a cooling coil (not shown)

10. Pump into the fermenter

The HLT is sized smaller so as to minimise the duration of temperature changes in multi step mashes.

The boil kettle is sized larger so as to avoid splashing / foaming over.

I have a false bottom on top of the mash tun as ell as the bottom to spread the recirculating wort across the entire surface. I have also seen people use the recirculation to cause (deliberately) rotation but I haven't understood the advantages and disadvantages yet - I'll ask this question in a separate thread in a different forum.

I would intend to use two pumps although if the piping is too long to recirculate (to maintain a consistent temperature) the water in the HLT (without too much cooling during its travels) then I'd add a third pump in order to shorten to circuit.

I'd intend that all entry / exit to the vessels would be tapped. The valves would be three way, one exit and two entries with a tap to switch between the entries.

Thanks in advance for all and any help.

Mike