luckybeagle

Making sales and brewing ales.

Warning, long post. I'd shorten it if I could! Any help is greatly appreciated.

I just finished putting together an eHERMS system with the following components:

I've done two brews on it: a 5 gallon Patersbier and a 10 gallon batch of Westmalle Tripel Clone.

On both of these batches, I've noticed the MLT lagging a bit in temperature when I am recirculating, which I've heard is normal. I AM recirculating water from the top down in the HLT, and am pumping sweet wort through the herms coil from the bottom up.

The Westmalle Tripel had a step mash with a rest at 124F followed by a saccharification rest at 147 and a mashout at 170F.

My process is to fill up the HLT to the brim, and my MLT to my desired strike volume. Then I begin the recirculating of the MLT through the herms coil, and the HLT from the bottom valve to the top (for even temperature distribution). I then dough-in at my desired temperature. No issues with that part of the process.

When the second step in my program kicks in (raise to sacc. temp of 147 for 60 minutes), the HLT heats up very quickly to this desired temperature, which in turn tells my PID to start the 60 minute timer. The problem is the grain is significantly lower than this temperature. Should I add 20 minutes to ensure the grain bed is thoroughly resting at 147F on a step mash like this?

When I increased my temperature to mash-out, the grain bed was 147F as intended, but I have no idea for how long. My 170F mashout temp was again reached in the HLT quickly, but the grain bed did not reach that temperature before the 20 minute timer elapsed. Should I add additional time to this, as well, or move on with fly sparging at this point?

Finally, and probably my biggest headscratcher, is how to maintain sparge water temperatures while fly sparging for one hour. Since I have to move the hoses around, the pump that was recirculating my HLT water is now moving water from the HLT to the MLT for sparging, and the other pump is moving the lautered sweet wort from the MLT to the BK. Since the flow is so slow and my PID controller's temperature probe is on my HLT water-out valve, it's reading a much lower temperature than what the water in the HLT is at. This causes my HLT to be fired up to boiling while the sparge water is at-or-below 170F. When I've stirred the HLT manually, the temperature coming in to sparge the grains jumps up to 190-200F+, which is wayy too hot. Should I just shut off the heat element once the HLT reaches 170 and sparge without the HLT heater firing?

Thanks so much for any and all advice.This is much more complicated than igloo cooler batch sparging, but I think it'll ultimately be great--if I can figure out how to run it right!

I just finished putting together an eHERMS system with the following components:

- 2x16 gallon Gasone Kettles (HLT and MLT)

- 1x15 gallon Concord Kettle (BK)

- 32ft 1/2" diameter Blichmann HERMS coil

- 2 x Amazon Brew pumps with stainless heads

- 2 x 5500w Camco water heaters

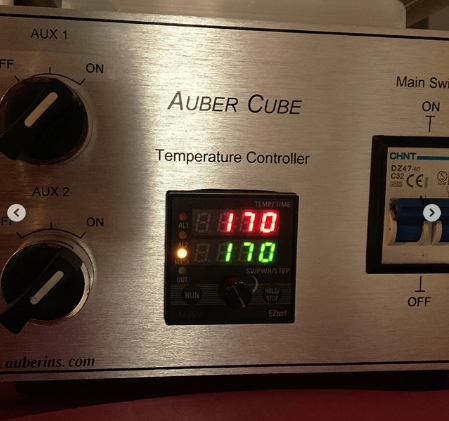

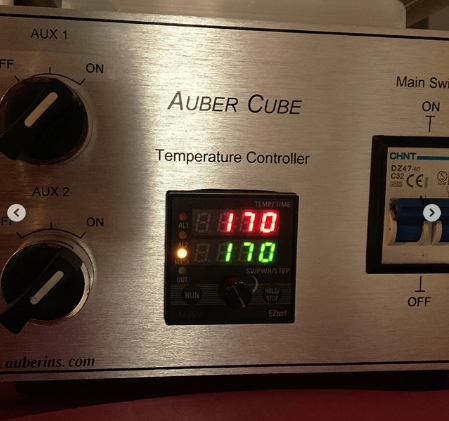

- Auber Cube 2E Controller

I've done two brews on it: a 5 gallon Patersbier and a 10 gallon batch of Westmalle Tripel Clone.

On both of these batches, I've noticed the MLT lagging a bit in temperature when I am recirculating, which I've heard is normal. I AM recirculating water from the top down in the HLT, and am pumping sweet wort through the herms coil from the bottom up.

The Westmalle Tripel had a step mash with a rest at 124F followed by a saccharification rest at 147 and a mashout at 170F.

My process is to fill up the HLT to the brim, and my MLT to my desired strike volume. Then I begin the recirculating of the MLT through the herms coil, and the HLT from the bottom valve to the top (for even temperature distribution). I then dough-in at my desired temperature. No issues with that part of the process.

When the second step in my program kicks in (raise to sacc. temp of 147 for 60 minutes), the HLT heats up very quickly to this desired temperature, which in turn tells my PID to start the 60 minute timer. The problem is the grain is significantly lower than this temperature. Should I add 20 minutes to ensure the grain bed is thoroughly resting at 147F on a step mash like this?

When I increased my temperature to mash-out, the grain bed was 147F as intended, but I have no idea for how long. My 170F mashout temp was again reached in the HLT quickly, but the grain bed did not reach that temperature before the 20 minute timer elapsed. Should I add additional time to this, as well, or move on with fly sparging at this point?

Finally, and probably my biggest headscratcher, is how to maintain sparge water temperatures while fly sparging for one hour. Since I have to move the hoses around, the pump that was recirculating my HLT water is now moving water from the HLT to the MLT for sparging, and the other pump is moving the lautered sweet wort from the MLT to the BK. Since the flow is so slow and my PID controller's temperature probe is on my HLT water-out valve, it's reading a much lower temperature than what the water in the HLT is at. This causes my HLT to be fired up to boiling while the sparge water is at-or-below 170F. When I've stirred the HLT manually, the temperature coming in to sparge the grains jumps up to 190-200F+, which is wayy too hot. Should I just shut off the heat element once the HLT reaches 170 and sparge without the HLT heater firing?

Thanks so much for any and all advice.This is much more complicated than igloo cooler batch sparging, but I think it'll ultimately be great--if I can figure out how to run it right!