Ok so this is pretty weird =]

I want to build a rotating dry hopper.

Lets say I have beer in a corny keg. I want to stick some hops in a small container and put that container in the keg. I want to attach the container to the lid of the corny keg, which will then be attached to a motor on the outside of the keg.

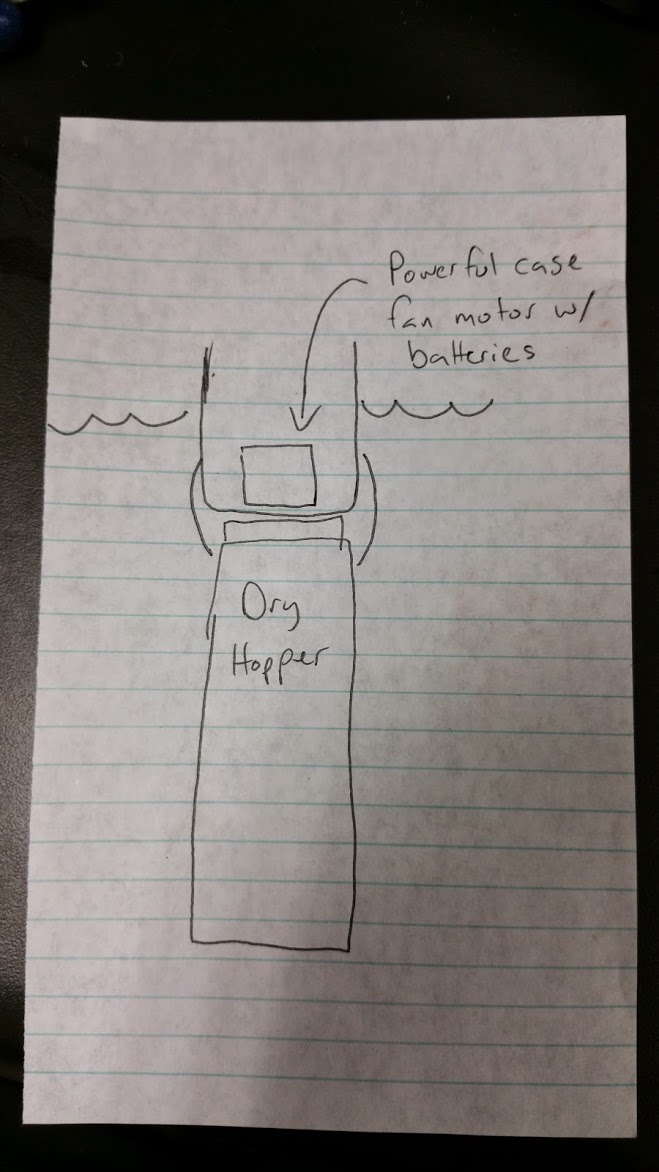

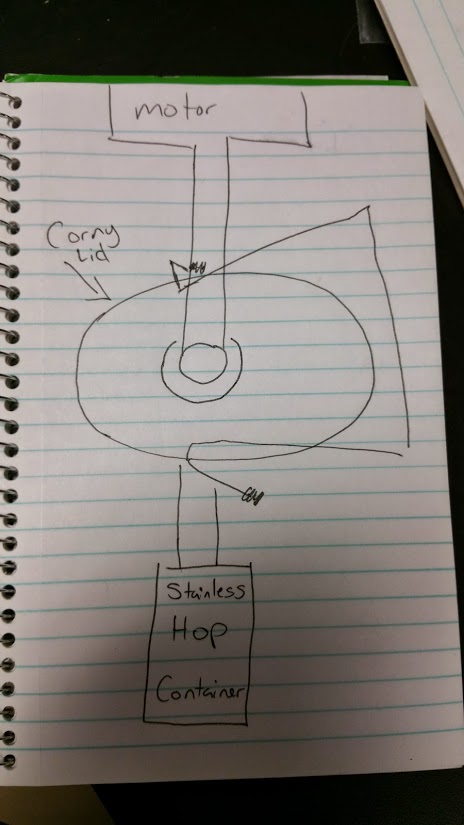

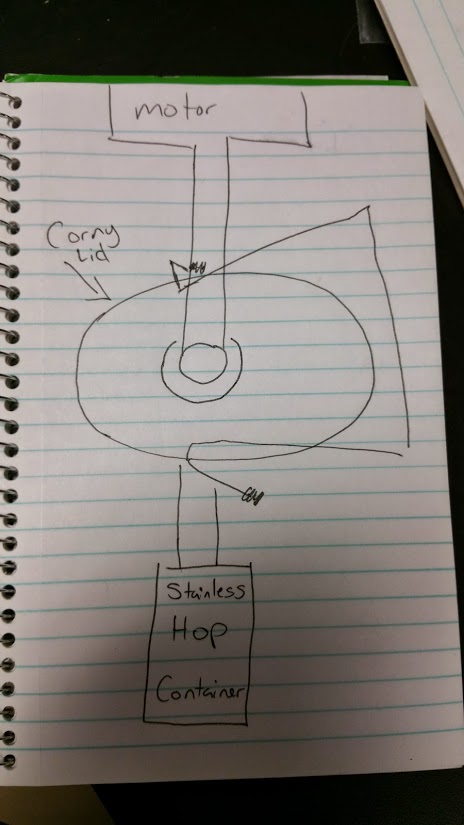

Here is a terrible drawing of the idea:

So the only issue is the thing I need to install in the keg lid. It ideally should be pressure capable and sanitary. Some sort of full enclosed pressure capable bearing would work, but I don't think that exists.

So I'm looking for ideas on how to do this. Any ideas greatly appreciated!

The easier way to do this would be to stick the keg on a rotating platform, but that would require a lot bigger motor, so I want to exhaust all options for the dry hop spinner first.

I want to build a rotating dry hopper.

Lets say I have beer in a corny keg. I want to stick some hops in a small container and put that container in the keg. I want to attach the container to the lid of the corny keg, which will then be attached to a motor on the outside of the keg.

Here is a terrible drawing of the idea:

So the only issue is the thing I need to install in the keg lid. It ideally should be pressure capable and sanitary. Some sort of full enclosed pressure capable bearing would work, but I don't think that exists.

So I'm looking for ideas on how to do this. Any ideas greatly appreciated!

The easier way to do this would be to stick the keg on a rotating platform, but that would require a lot bigger motor, so I want to exhaust all options for the dry hop spinner first.