The title says almost all of it. I usually end the year by running starsan through the lines and leaving them, however I just found that I forgot to do it last year. I opened it up today and ran some sanitizer through it, and there are some funky floaties. How do I clean out these metal lines?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help! I forgot to clean out the lines in my jockey box last year.

- Thread starter Stoney28

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

You'd need more than a mere sanitizer to clean the gunk out.

Recirculate, a warm/somewhat hot (definitely not boiling) PBW (or Oxiclean) solution through the coils. Or fill then let stand for an hour or so, flush, repeat, until clean.

You could add a small amount of drain cleaner (Sodium Hydroxide, NaOH) to the alkaline cleaning solution for extra oomph. Wear gloves and eye protection. Seriously!

Once the coils are clean, check the vinyl connection lines, QDs, faucets, and connectors for being clean too. Or soak and brush out separately. Vinyl lines are easily replaced too.

When everything is clean, run water through them to flush out the cleaner, followed by sanitizer.

Recirculate, a warm/somewhat hot (definitely not boiling) PBW (or Oxiclean) solution through the coils. Or fill then let stand for an hour or so, flush, repeat, until clean.

You could add a small amount of drain cleaner (Sodium Hydroxide, NaOH) to the alkaline cleaning solution for extra oomph. Wear gloves and eye protection. Seriously!

Once the coils are clean, check the vinyl connection lines, QDs, faucets, and connectors for being clean too. Or soak and brush out separately. Vinyl lines are easily replaced too.

When everything is clean, run water through them to flush out the cleaner, followed by sanitizer.

Last edited:

Hot PBW soak for 1 day, rinse, sanitize.

I went nuclear on a keg that went out-of-control infected. Ended up burning a hole in it - turns out straight bleach in a corny will indeed etch through stainless steel. I had heard that but didn't believe it.

Oh well. Now I'm gonna go put my hand on the stovetop to see if it's actually hot. BRB

There is nothing quite like experimentation.I went nuclear on a keg that went out-of-control infected. Ended up burning a hole in it - turns out straight bleach in a corny will indeed etch through stainless steel. I had heard that but didn't believe it.

Oh well. Now I'm gonna go put my hand on the stovetop to see if it's actually hot. BRB

In a lifetime, and it's nearly that for me, you do experience a lot of things, and you learn. That's called wisdom. I imagine some people really are geniuses and don't require the failures, but I'm not one of those.

I hope we hear back from @Stoney28. His situation is common and correctable. I'm glad he found our forum and asked.

I hope we hear back from @Stoney28. His situation is common and correctable. I'm glad he found our forum and asked.

FYI, although the name may suggest it being a specialty product, that stuff is not all that magical at cleaning beer lines.

It's not any better than PBW (or just TSP/90) + some Sodium Hydroxide (Lye, drain opener) added. For good measure one could add a little EDTA to that, but not all that critical.

From BLC's MSDS:

Potassium Hydroxide 5-10%

Tetrapotassium Pyrophosphate ≤ 2.5%

Disodium Metasilicate ≤ 2.5%

The latter is known as TSP/90; PBW or a homemade version contains 30% of it.

In short, it's mostly water... 85-90%

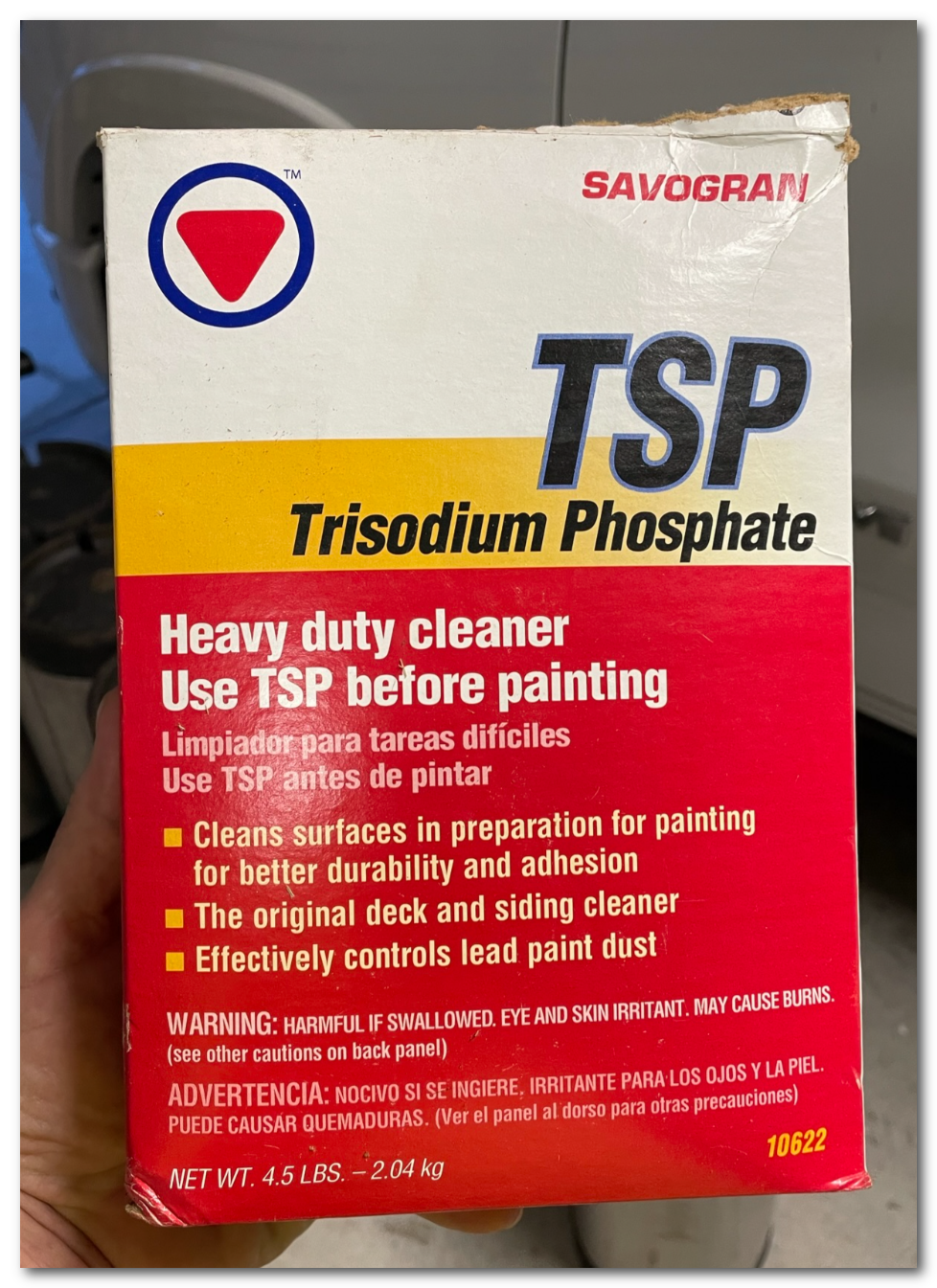

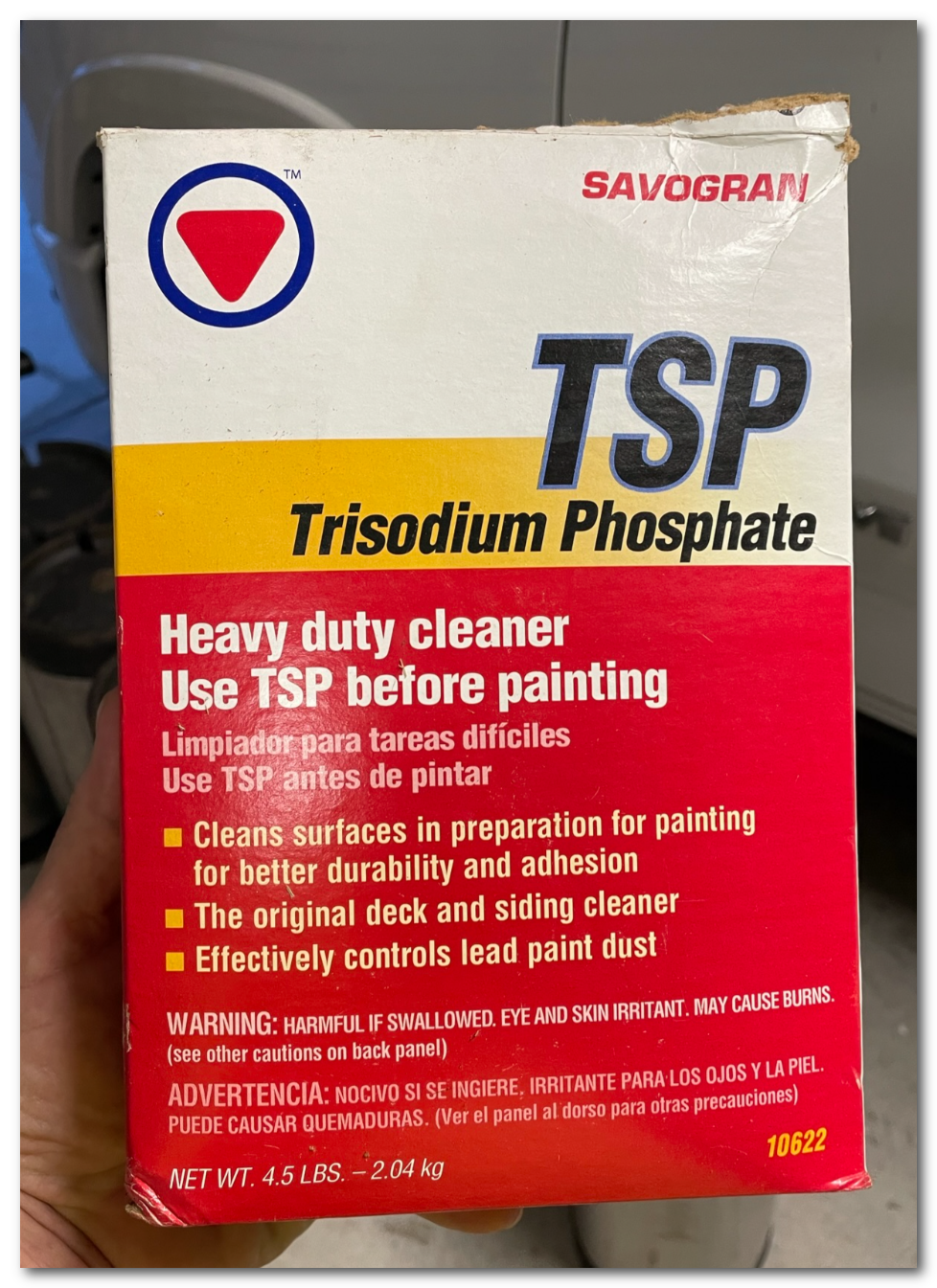

I thought you couldn't buy TSP anymore?

As long as you're using food-grade caustic I think that's probably right.FYI, although the name may suggest it being a specialty product, that stuff is not all that magical at cleaning beer lines.

It's not any better than PBW (or just TSP/90) + some Sodium Hydroxide (Lye, drain opener) added. For good measure one could add a little EDTA to that, but not all that critical.

From BLC's MSDS:

Potassium Hydroxide 5-10%

Tetrapotassium Pyrophosphate ≤ 2.5%

Disodium Metasilicate ≤ 2.5%

The latter is known as TSP/90; PBW or a homemade version contains 30% of it.

In short, it's mostly water... 85-90%

TSP (Tri Sodium Phosphate) was mainly "outlawed" for a few decades as it contains Phosphates that ended up in effluents, and thus eventually in surface water, causing algae blooms, resulting in suffocating lakes and ponds.I thought you couldn't buy TSP anymore?

TSP/90 is Disodium MetaSilicate and thus phosphate free. You can get bags of it in hardware stores. It's the 30% component in PBW. The balance (70%) being mostly Sodium Percarbonate (also found as a major component in Oxiclean).

They shoulda called it DS/90!

But nobody would recognize it by that name, which is a main part of marketing.They shoulda called it DS/90!

TSP/90 was the substitute for TSP. there's name recognition. On some containers it even reads: Phosphor-free TSP substitute. No clue what the 90 stands for, except the notion that higher numbers tend to sell better.

Let me correct myself, only 16 states banned the use of (original) TSP. But there are ways around it, for example, certain contractors could still use it and they have...

Here's an interesting sum-up of some very dangerous, highly toxic chemicals that were commonly used around homes in the not so far past, and without being questioned at the time:

https://www.thisoldhouse.com/home-safety/21018179/9-highly-toxic-old-household-products

'nuf sed!

We have straight TSP at home depot down here in FL. Paint dept. Your situation might be different.

Last edited by a moderator:

I was just thinking about this. Would you consider TSP to be a "very dangerous, highly toxic chemical. If your answer is yes, then I will bow out of this conversation immediately.But nobody would recognize it by that name, which is a main part of marketing.

TSP/90 was the substitute for TSP. there's name recognition. On some containers it even reads: Phosphor-free TSP substitute. No clue what the 90 stands for, except the notion that higher numbers tend to sell better.

Let me correct myself, only 16 states banned the use of (original) TSP. But there are ways around it, for example, certain contractors could still use it and they have...

Here's an interesting sum-up of some very dangerous, highly toxic chemicals that were commonly used around homes in the not so far past, and without being questioned at the time:

https://www.thisoldhouse.com/home-safety/21018179/9-highly-toxic-old-household-products

'nuf sed!

BrewerofBeers

Well-Known Member

Oh, dear friend, don't be so quick to just use PBW alone, It's a fantastic cleaner, no doubt, but on its own it's prone to leaving behind residue, especially on stainless surfaces, So before you call it a day, let me give you some cleansing services.

First things first, warm up some water and add PBW to it, Give it a good shake or some circulation to really let it sit. Let your items soak for a bit, let PBW do its thing, And then rinse with water, until you see the suds take wing.

But wait, there's more, don't stop there, it's not yet done, After PBW, you need an acid to make sure it's really gone. And when it comes to acids, vinegar is my personal pick, So soak your items in vinegar, and give it a good shake and flick.

Let it sit for a while, until the acid has done its work, And then rinse again with water, don't let any residue lurk. With this two-step cleaning process, your items will be pristine, And you'll be glad you took the time to make sure they're clean.

First things first, warm up some water and add PBW to it, Give it a good shake or some circulation to really let it sit. Let your items soak for a bit, let PBW do its thing, And then rinse with water, until you see the suds take wing.

But wait, there's more, don't stop there, it's not yet done, After PBW, you need an acid to make sure it's really gone. And when it comes to acids, vinegar is my personal pick, So soak your items in vinegar, and give it a good shake and flick.

Let it sit for a while, until the acid has done its work, And then rinse again with water, don't let any residue lurk. With this two-step cleaning process, your items will be pristine, And you'll be glad you took the time to make sure they're clean.

Last edited:

No need to bow out. TSP is by far the lesser noxious in that line-up. But one should not get it in their eyes, inhale the dry powder, while skin contact should be generally avoided or kept to a minimum, etc.I was just thinking about this. Would you consider TSP to be a "very dangerous, highly toxic chemical. If your answer is yes, then I will bow out of this conversation immediately.

My wife is impressed with your nod to meter and lyrical stylings. Thank you for your ideas, as well as their delivery.Oh, dear friend, don't be so quick to just use PBW alone, It's a fantastic cleaner, no doubt, but on its own it's prone to leaving behind residue, especially on stainless surfaces, So before you call it a day, let me give you some cleansing services.

First things first, warm up some water and add PBW to it, Give it a good shake or some circulation to really let it sit. Let your items soak for a bit, let PBW do its thing, And then rinse with water, until you see the suds take wing.

But wait, there's more, don't stop there, it's not yet done, After PBW, you need an acid to make sure it's really gone. And when it comes to acids, vinegar is my personal pick, So soak your items in vinegar, and give it a good shake and flick.

Let it sit for a while, until the acid has done its work, And then rinse again with water, don't let any residue lurk. With this two-step cleaning process, your items will be pristine, And you'll be glad you took the time to make sure they're clean.

- Joined

- Jan 6, 2008

- Messages

- 154

- Reaction score

- 19

These products are significantly cheaper than 5star stuff. Anyone use these on a regular basis? I use the 5star Beer Stone remove about once a years on my system and it's like $8 for a couple onces.

The pricing on many of their products is roundout crazy. They don't contain exotic ingredients justifying those.These products are significantly cheaper than 5star stuff. Anyone use these on a regular basis? I use the 5star Beer Stone remove about once a years on my system and it's like $8 for a couple onces.

Look up the ingredients (MSDS) and buy generics in bulk and mix your own. That's why many of us use homemade PBW, at less than 1/5 of the cost of a 1 pound canister or about 1/2 the cost if bought in 50# pails (and split with other homebrewers).

"I usually end the year by running starsan through the lines and leaving them"

Starsan is not a cleaner and you cannot sanitize what isn't first cleaned. That being said, tubing is cheap. Replace it.

Starsan is not a cleaner and you cannot sanitize what isn't first cleaned. That being said, tubing is cheap. Replace it.

I seriously doubt it would do a better job than PBW, given the ingredients in BLC and their (heavy) dilution.I might try the line cleaner, though too.

Chemical composition, concentration, contact time (e.g., soaking), temperature, and agitation (e.g., recirculation, pumping, pressure) are key variables in any cleaning system. A mechanical scrubber could shorten the time, but tricky to implement with long narrow coils.

Did you add some lye (e.g., Sodium Hydroxide, alkaline drain cleaner) to the PBW?

BTW, shout out for saniclean. That stuff gets rid of any left over aromas and flavors from plastic lines. I used it on some lines I served root beer from and then switched over to water. Zero leftover flavor or aroma.

VikeMan

It ain't all burritos and strippers, my friend.

- Joined

- Aug 24, 2010

- Messages

- 5,853

- Reaction score

- 5,970

The title says almost all of it. I usually end the year by running starsan through the lines and leaving them, however I just found that I forgot to do it last year.

There's been some good advice on fixing the issue.

But I'll add...

Jockey box lines should be cleaned and sanitized after every use, not just at the end of a season. My process, on same day as event:

- push beer out

- CIP the Beer Lines/Plates/Coils/Faucets with recirculating BLC

- Rinse

- Sanitize with properly diluted Iodophor (do not stain the lines with Iodophor solution that is too concentrated.

- Blow CO2 (or Air) through Lines/Plates/Coils/Faucets to dry

- Leave Faucets Open

- Remove, disassemble, clean, let dry, and reassemble Liquid QDs (don't reinstall during storage)

- Store Box with Lid and Faucets open (to continue drying)

I've seen some pretty nasty stuff in (and on) club jockey box lines and in the boxes themselves. And once there's something growing, it can be pretty hard to get rid of it permanently. For whatever reason, a lot of people think that jockey boxes don't need the same level of care as other cold side equipment.

- Joined

- Jan 3, 2020

- Messages

- 2,273

- Reaction score

- 2,357

Is there a particular reason you use iodophor vs. starsan or saniclean?There's been some good advice on fixing the issue.

But I'll add...

Jockey box lines should be cleaned and sanitized after every use, not just at the end of a season. My process, on same day as event:

- push beer out

- CIP the Beer Lines/Plates/Coils/Faucets with recirculating BLC

- Rinse

- Sanitize with properly diluted Iodophor (do not stain the lines with Iodophor solution that is too concentrated.

- Blow CO2 (or Air) through Lines/Plates/Coils/Faucets to dry

- Leave Faucets Open

- Remove, disassemble, clean, let dry, and reassemble Liquid QDs (don't reinstall during storage)

- Store Box with Lid and Faucets open (to continue drying)

I've seen some pretty nasty stuff in (and on) club jockey box lines and in the boxes themselves. And once there's something growing, it can be pretty hard to get rid of it permanently. For whatever reason, a lot of people think that jockey boxes don't need the same level of care as other cold side equipment.

Do you use a pump to recirc? I have the connections to chain my four coils together but my March and Riptide pumps aren't strong enough to even do two at time, too much resistance. I will give my Spike Flow a shot but I doubt it will either. So I have been wondering what size pump might do at at least two coils (I have 2 fifty 2 seventy foot coils).

VikeMan

It ain't all burritos and strippers, my friend.

- Joined

- Aug 24, 2010

- Messages

- 5,853

- Reaction score

- 5,970

Is there a particular reason you use iodophor vs. starsan or saniclean?

Iodophore is a broader spectrum sanitizer than starsan. And it's cheaper. But the main reason I like it for tubing is that it doesn't leave a chalky or slimy film on vinyl like starsan can. And since I clean my jockey boxes outside, I don't worry much about iodophore staining anything while mixing/splashing. That said, I have also used starsan for jockey boxes at times.

Do you use a pump to recirc? I have the connections to chain my four coils together but my March and Riptide pumps aren't strong enough to even do two at time, too much resistance. I will give my Spike Flow a shot but I doubt it will either. So I have been wondering what size pump might do at at least two coils (I have 2 fifty 2 seventy foot coils).

Yes. I use a "pond pump" rated at 21 GPM, but I do one coil (or plate line) at a time. I haven't tried ganging coils/lines together.

Connect them in parallel, cleaning them all at once. As long as liquid moves through the lines it's cleaning, high speed is not needed. Now warm or hot cleans better than cold, many chemical reactions typically double in speed at every 10°C temp increase.I have the connections to chain my four coils together but my March and Riptide pumps aren't strong enough to even do two at time, too much resistance. I will give my Spike Flow a shot but I doubt it will either. So I have been wondering what size pump might do at at least two coils (I have 2 fifty 2 seventy foot coils).

- Joined

- Jan 3, 2020

- Messages

- 2,273

- Reaction score

- 2,357

I've had a short pumps course and could be wrong here but I don't think it matters whether the lines are parallel or in series. I think one would add up the total resistence of both lines after the pump. Two or more pumps however it does make a difference whether the pumps are in series or parallel but I need to refresh my memory on that as to how it works as it just occurred to me that could be a solution.Connect them in parallel, cleaning them all at once. As long as liquid moves through the lines it's cleaning, high speed is not needed. Now warm or hot cleans better than cold, many chemical reactions typically double in speed at every 10°C temp increase.

Each line/coil has resistance. In series, all those resistances are added, reducing the flow.I don't think it matters whether the lines are parallel or in series.

In parallel, the pump's max head pressure, and thus flow rate, limits the total flow through all coils combined.

- Joined

- Jan 3, 2020

- Messages

- 2,273

- Reaction score

- 2,357

Gotcha thanks! I COMPLETELY forgot the section on laterals and anything more advanced. I did find my course notes. Thinking back, I did previously see at least one mention of using a manifold for something like this in the forum but it didn't strike a chord. Now if I am reading my notes correctly, I could put my two pumps in series to try to clean two coils at once, since I couldn't even pump through two coils before. However, sounds like a manifold (2 or 4 way) would be the better option and I could increase the flow rate by putting the pumps in parallel. Looks like I have all the fittings I need except a couple of ptc tees. It was drudgery doing these one at a time!Each line/coil has resistance. In series, all those resistances are added, reducing the flow.

In parallel, the pump's max head pressure, and thus flow rate, limits the total flow through all coil combined.

@Stoney28 I have Intertap faucets on my jockey box. These have threaded spouts, and there is a growler attachment that threads into the faucet with a barb. On my brew rig, I will then run the line back to my BK where I can keep PBW warm and feed it to my pumps. From the pump to a barbed x ball lock QD will get the cleaning solution to the coils. Since I have Evabarrier tubing, I can build a manifold out of three ptc tees and a ball lock disconnect, since I am trying to do them all at once.

Similar threads

- Replies

- 14

- Views

- 2K

- Replies

- 3

- Views

- 1K