I put hard in quotes as I don't need everything to be stainless fittings and pipe, but I wanted to figure out a way to have all my hose connections in place where I can direct wort flow with valves instead of disconnecting and moving them around the ports on the system like a switchboard. End result would still use my silicone hoses, but in conjunction with stainless tee's and butterfly valves. Looking for any tips from people that have done this with their system so I can start designing one for myself. Pics would be great!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"Hard" plumbing for 3 vessel E-HERMS system

- Thread starter kgranger

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

While I haven't done such a setup and am a single vessel BIAB brewer, let me suggest that you assemble your fixed plumbing site using TC clamps, pipes, tees and valves instead of threaded fittings. My logic behind this additional complication and possible cost is the ease to a) strip apart and rearrange if needed, b) cleaning some fixed items on an irregular basis might be easier if stripped, and c) adding or removing features as your fancy takes you is easier.

Just my $2 (TC isn't exactly cheap is it, but you do get butterfly valves that have TC flanges machined into them already)

Just my $2 (TC isn't exactly cheap is it, but you do get butterfly valves that have TC flanges machined into them already)

I definitely plan to go TC, I don't mind the extra expensive for ease of cleaning and removabilityWhile I haven't done such a setup and am a single vessel BIAB brewer, let me suggest that you assemble your fixed plumbing site using TC clamps, pipes, tees and valves instead of threaded fittings. My logic behind this additional complication and possible cost is the ease to a) strip apart and rearrange if needed, b) cleaning some fixed items on an irregular basis might be easier if stripped, and c) adding or removing features as your fancy takes you is easier.

Just my $2 (TC isn't exactly cheap is it, but you do get butterfly valves that have TC flanges machined into them already)

1/2" stainless tubing isnt much more than silicone. (less than $3/ft) if you get TC fittings with 1/2" compression ends you're all set. use a 1/2 conduit bender to make your bends. its pretty damn easy. same amount of TC fittings.

of course, if you dont have a brew stand (or fixed arrangement of your gear) then it loses its appeal.

of course, if you dont have a brew stand (or fixed arrangement of your gear) then it loses its appeal.

Actually haven't thought about using SS tubing, always just pictured larger spools with welded TC ends.1/2" stainless tubing isnt much more than silicone. (less than $3/ft) if you get TC fittings with 1/2" compression ends you're all set. use a 1/2 conduit bender to make your bends. its pretty damn easy. same amount of TC fittings.

of course, if you dont have a brew stand (or fixed arrangement of your gear) then it loses its appeal.

Either way, regardless of what exact materials I plan to use, what I am mainly looking for is advice on the layout designing for wort flow, i.e. placement of valves and tee's, etc.

- Joined

- Jan 3, 2020

- Messages

- 2,272

- Reaction score

- 2,357

Will you be using 1 or 2 pumps and what type of chiller? If using two pumps are you dedicating one for water only? Whirlpool/return port on your BK?

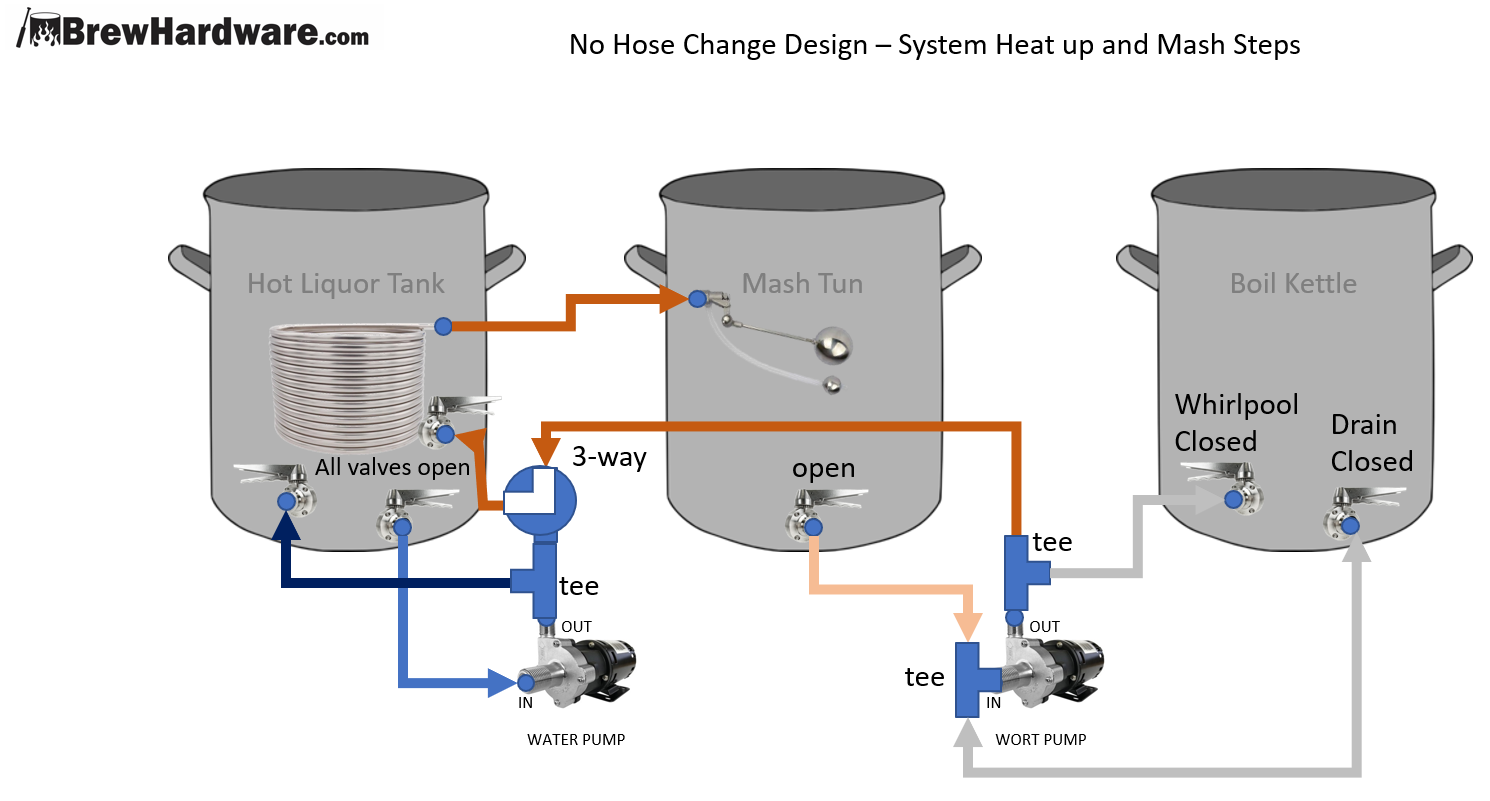

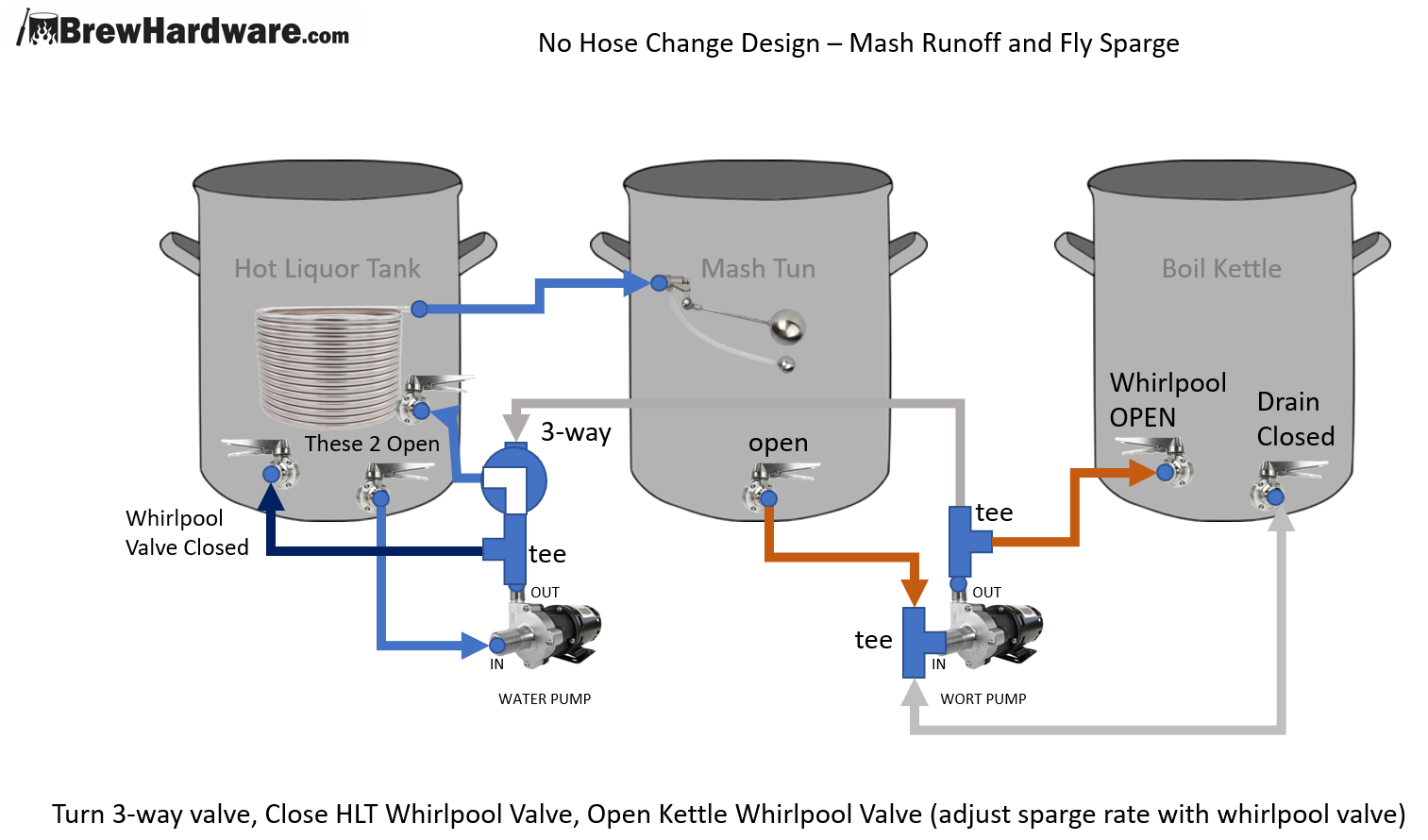

Using 2 pumps, one will be HLT only, so just water, other will switch between mash recirculation and brew kettle. Using a counterflow chiller. And yes there is a return port for the BK. It's a standard Spike brewing trio system.Will you be using 1 or 2 pumps and what type of chiller? If using two pumps are you dedicating one for water only? Whirlpool/return port on your BK?

TC clamps

I do agree with your post but this reminded me - one thing that bugs me about moving around tri-clamp fitting is temperatures. Depending on where you have them you may need gloves on to be able to make a swap and not burn yourself. It's easily overcome by having gloves around, but a bit of an annoyance at times. Not a show stopper but maybe something to consider.

Using spools to hard pipe vessel to pump and three way valves I do not have to change hoses during the process. I have two open ports on three way valves to connect short hoses to my stout SS counterflow chiller when it is time. Still some silicone but that makes it easier to move something if I need to.

Attachments

Awesome, this is exactly what I was looking for, thanks Bobby!It can be done mostly with tees but it will require either a 3 way valve or a tee with two output butterflys.

Using spools to hard pipe vessel to pump and three way valves I do not have to change hoses during the process. I have two open ports on three way valves to connect short hoses to my stout SS counterflow chiller when it is time. Still some silicone but that makes it easier to move something if I need to.

OT: do you have a thread or video on your setup ? What is your typical batch size ?

Awesome, this is exactly what I was looking for, thanks Bobby!

One thing I realized is that you COULD move that 3-way valve directly onto the HERMS coil port and erase that butterfly.

Similar threads

- Replies

- 39

- Views

- 791

- Replies

- 2

- Views

- 350

- Replies

- 4

- Views

- 565

- Replies

- 0

- Views

- 416

- Replies

- 3

- Views

- 1K