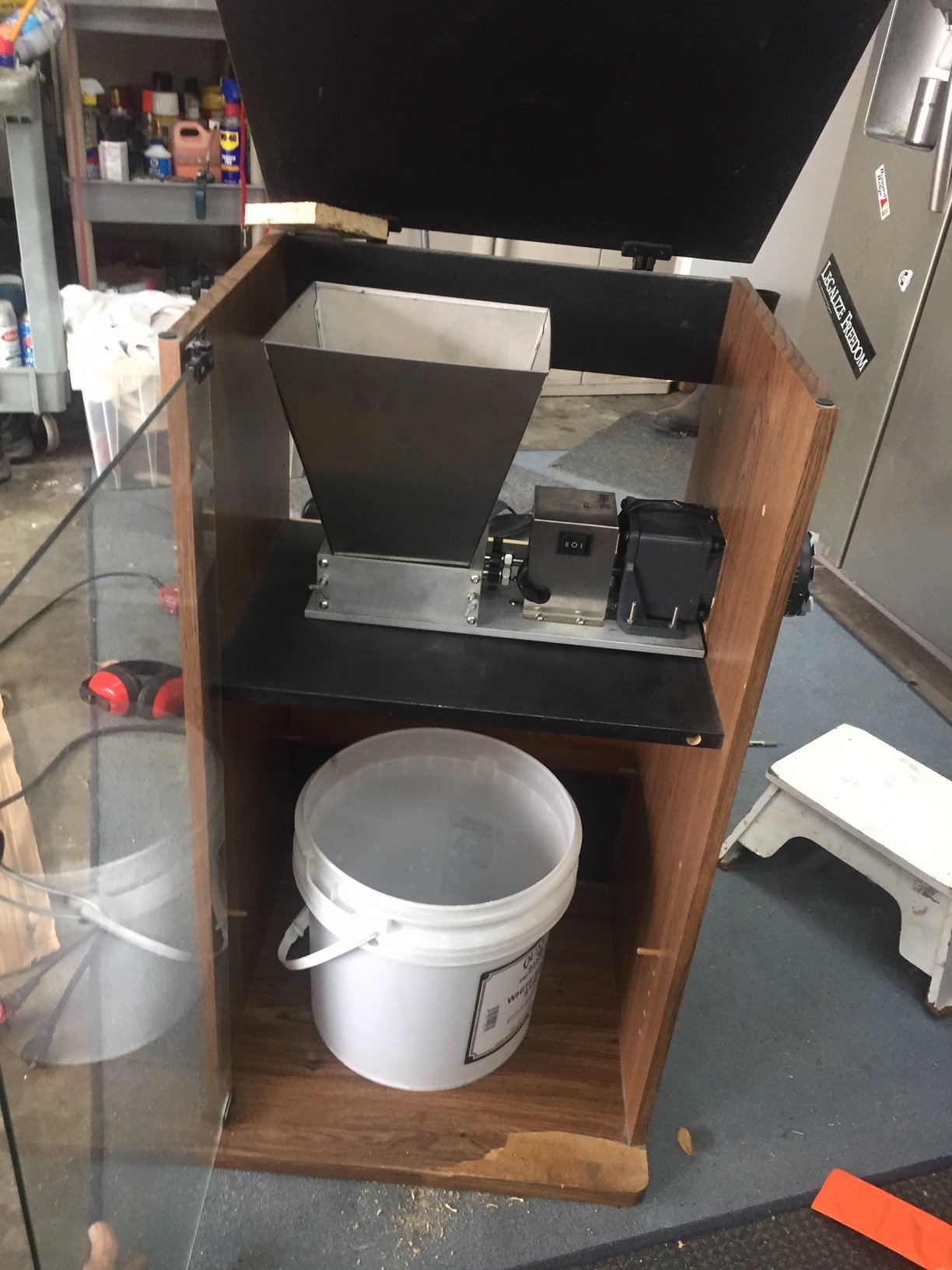

I need to build a stand/cart for my grain mill and I need some ideas. Right now I just have the mill screwed to a piece of plywood plopped over a bucket sitting on the floor. My old knees and back need it off the floor and on wheels.

Let's see what you got!

Let's see what you got!

)

)

....

....