Toto's

Well-Known Member

hello,

i an new in this forum and i am really learning a lot, thank you so much for your knowledge sharing!!! i use to do a few batch on a gas stove in my kitchen but i would like to change that even if my girlfriend is really understanding and supportive and never said a work lol. I have a basement where i can set up a new system. Here is my actual material:

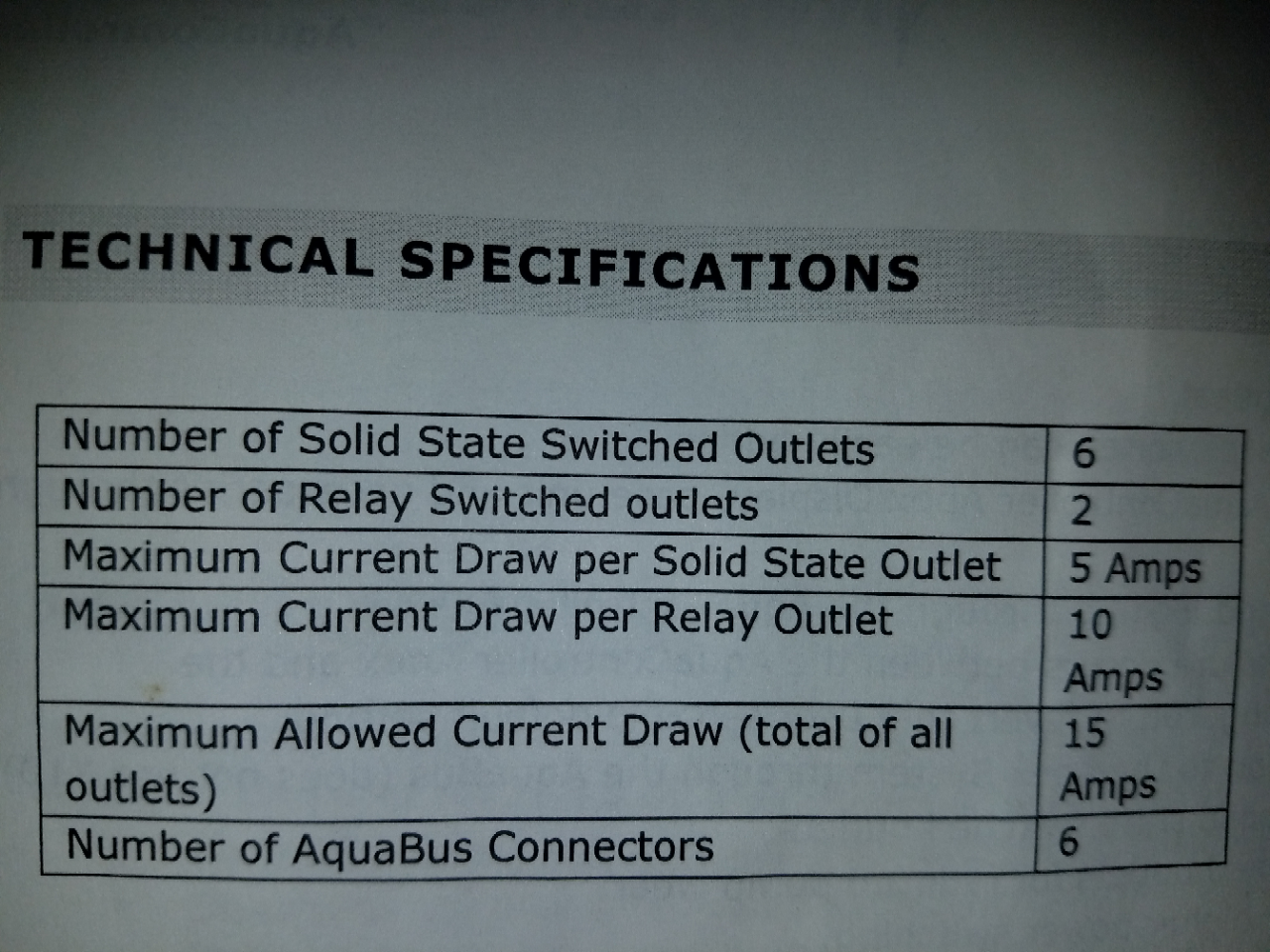

beer me boiler 30L. a kettle with 2 holes 30L. apex controller (https://www.neptunesystems.com/products/apex-controllers/apex-controller-system/)

i was thinking to recycle my controller which is design for salt aquariums but i think i can make it do beer since i quit the salt aquarium many years ago. it can be programmed to heat/stop heating, switch box, start any electrical devise you plug in the outlet you just need to program it. has ph and temperature probe .... can even send you an email !!!! lol

would not mind to get a 15 gallons kettle to improve the beer production. I know i need pump probably the Chugger Brew Pump - Inline Stainless Steel Head because i have a budget to respect lol. I am fully equipped with tools so no problems on that matter.

so here is the first question ...

1) Did someone already use a aquarium controller to make beer?

2) RIMS or HERMS

3) will go for standardizing the connections with camlocks but should i go with the 1/2 or 5/8?

4) for the cooling I was planing to go with something like that:

I was debating between plates VS immersions but I will go for lagers and read plates not so good for those type of beers... true?

Grey Kingsnake Stainless Steel Immersion Wort Chiller - 50' x 1/2"

https://www.ontariobeerkegs.com/ProductDetails.asp?ProductCode=ss-wort-chiller-50-12-gh&CartID=3

I guess I can use it as heating as well if I go for a HERMS. any comment?

5) I was looking how to install the temperature probe... should i put one just before it goes in the kettle? What is the system connection? is it a probe with NPT attachment system?

6) filtration .... i do wine too and would like to use something to filter beer and wine so will be able to stop putting yeast killer into my wine and will be 100% natural!! lol

is there something like this: Advanced beer filtering kit but can I use the Chugger Brew Pump instead of CO2? https://www.ontariobeerkegs.com/Advanced_Beer_Filtering_Kit_p/adv-beer-filtering-kit.htm

Well for now its all. I will try to take advantage of the black friday weed-end to get some equipment.

i an new in this forum and i am really learning a lot, thank you so much for your knowledge sharing!!! i use to do a few batch on a gas stove in my kitchen but i would like to change that even if my girlfriend is really understanding and supportive and never said a work lol. I have a basement where i can set up a new system. Here is my actual material:

beer me boiler 30L. a kettle with 2 holes 30L. apex controller (https://www.neptunesystems.com/products/apex-controllers/apex-controller-system/)

i was thinking to recycle my controller which is design for salt aquariums but i think i can make it do beer since i quit the salt aquarium many years ago. it can be programmed to heat/stop heating, switch box, start any electrical devise you plug in the outlet you just need to program it. has ph and temperature probe .... can even send you an email !!!! lol

would not mind to get a 15 gallons kettle to improve the beer production. I know i need pump probably the Chugger Brew Pump - Inline Stainless Steel Head because i have a budget to respect lol. I am fully equipped with tools so no problems on that matter.

so here is the first question ...

1) Did someone already use a aquarium controller to make beer?

2) RIMS or HERMS

3) will go for standardizing the connections with camlocks but should i go with the 1/2 or 5/8?

4) for the cooling I was planing to go with something like that:

I was debating between plates VS immersions but I will go for lagers and read plates not so good for those type of beers... true?

Grey Kingsnake Stainless Steel Immersion Wort Chiller - 50' x 1/2"

https://www.ontariobeerkegs.com/ProductDetails.asp?ProductCode=ss-wort-chiller-50-12-gh&CartID=3

I guess I can use it as heating as well if I go for a HERMS. any comment?

5) I was looking how to install the temperature probe... should i put one just before it goes in the kettle? What is the system connection? is it a probe with NPT attachment system?

6) filtration .... i do wine too and would like to use something to filter beer and wine so will be able to stop putting yeast killer into my wine and will be 100% natural!! lol

is there something like this: Advanced beer filtering kit but can I use the Chugger Brew Pump instead of CO2? https://www.ontariobeerkegs.com/Advanced_Beer_Filtering_Kit_p/adv-beer-filtering-kit.htm

Well for now its all. I will try to take advantage of the black friday weed-end to get some equipment.